Combined fixture used for fixing optical fiber stress rod

A technology of optical fiber stress and combined fixture, which is applied in the direction of grinding workpiece brackets, etc., can solve problems such as difficulty in ensuring circular symmetry, deviation of the concentricity of optical fiber stress rods, and affecting the quality of optical fibers, etc., to achieve the goal of overcoming excessive dependence and good circular symmetry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

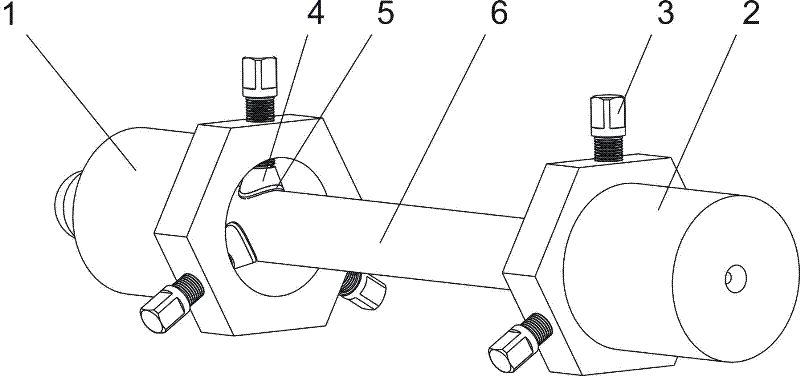

[0025] Such as figure 1 As shown, a combined clamp for fixing optical fiber stress rods of the present invention includes left fasteners 1 and right fasteners 2 for clamping both sides of optical fiber stress rods 6, and six sets of helical columns 3, clamping heads 4 and Gasket 5, specifically as follows.

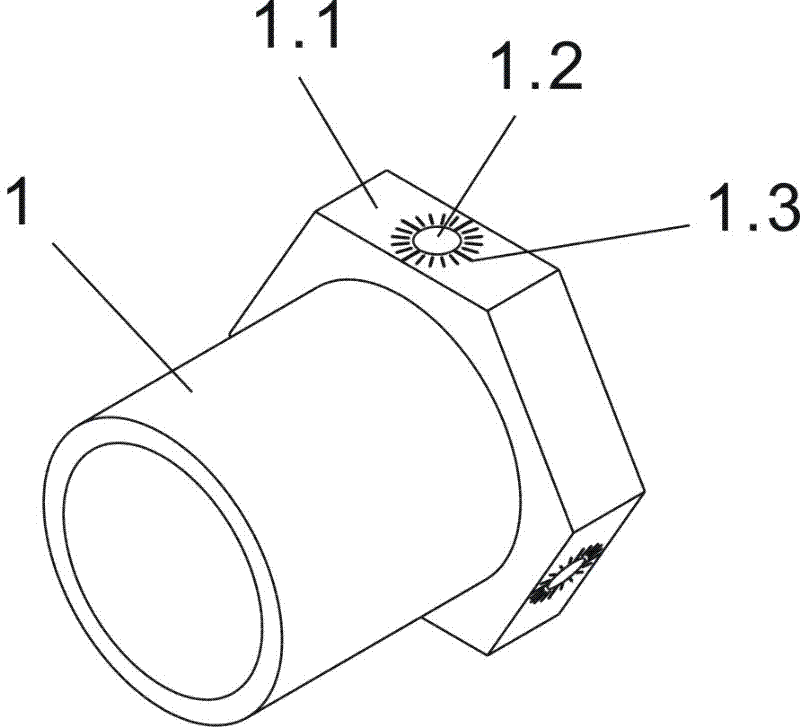

[0026] Such as figure 2 As shown, the left fixture 1 is hollow and cylindrical, and the outer surface of the left fixture 1 side is provided with a regular hexagonal flange 1.1, and the flange 1.1 is evenly provided with three radial screw holes 1.2, which are used to install the screw column 3 .

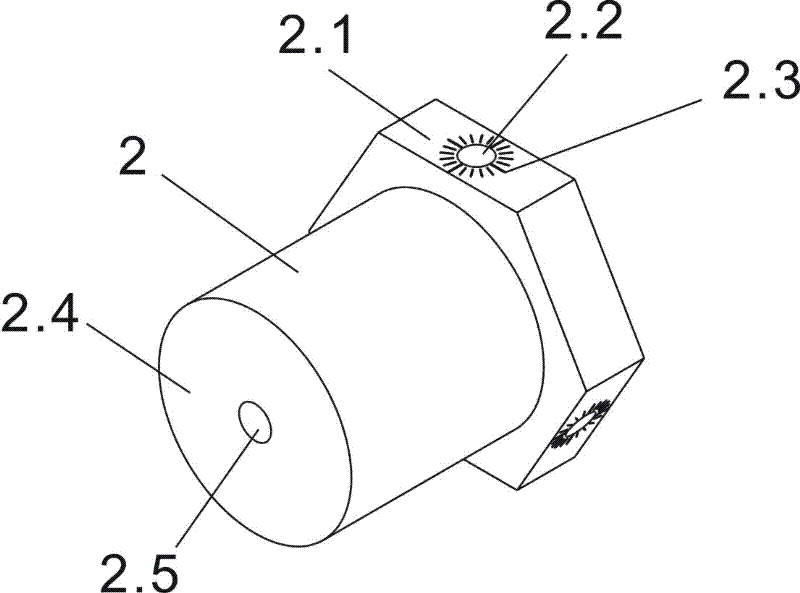

[0027] Such as image 3 and Figure 4 As shown, the right fixture 2 is cylindrical with one end closed, and the outer surface of the right fixture 2 side is provided with a flange 2.1, and the flange 2.1 is evenly provided with thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com