An annular stress zone-birefringence polarization-maintaining optical fiber and its preparation method

A technology of polarization-maintaining fiber and stress zone, which is applied in the direction of polarization-maintaining fiber, cladding fiber, glass manufacturing equipment, etc., can solve the problems that the core is not in a perfect circle, the fiber loses circular symmetry, and cannot be used to prepare circular polarization-maintaining fiber. Achieve the effects of high production efficiency, strong anti-interference ability and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

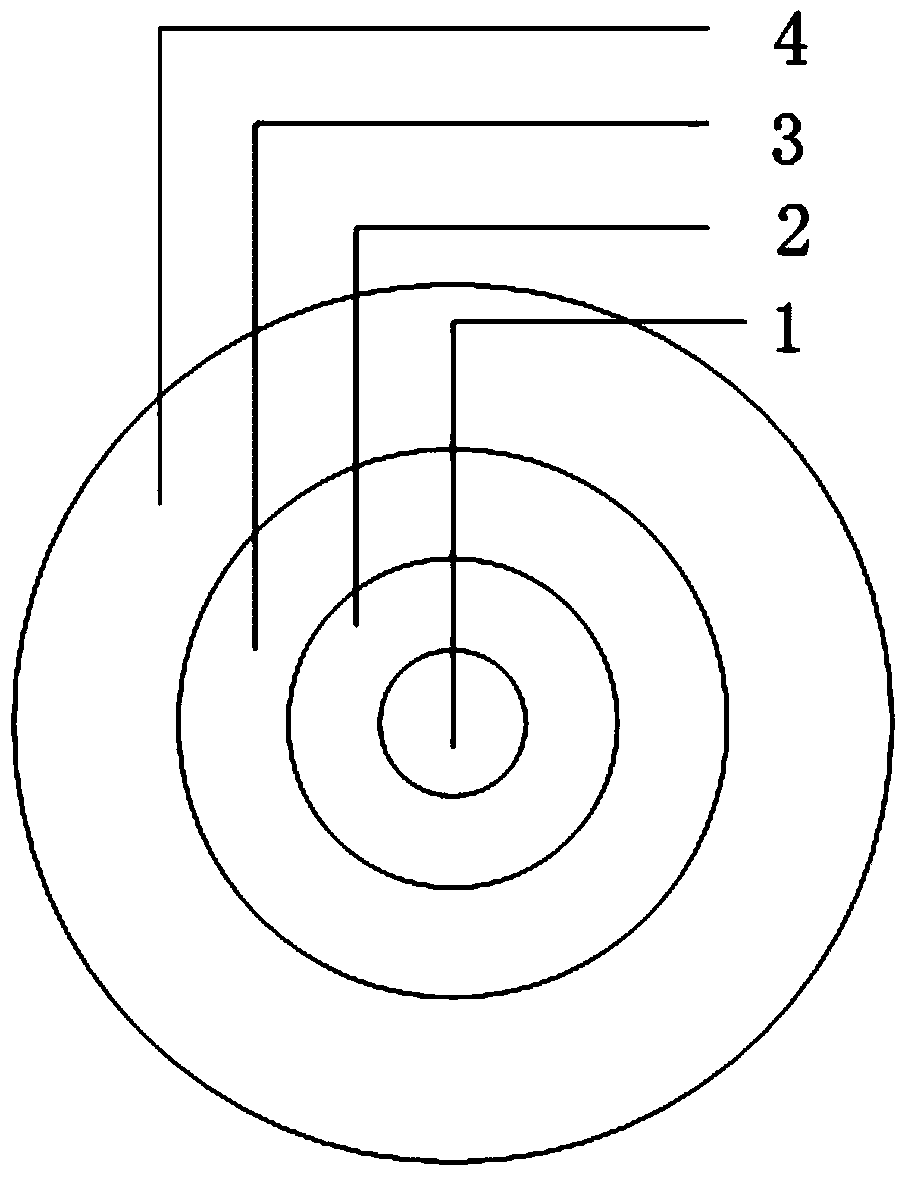

Image

Examples

Embodiment 1

[0031] A method for preparing an annular stress zone-birefringence polarization-maintaining optical fiber, specifically comprising the following steps:

[0032] (1) Depositing the outer cladding: control the deposition temperature to 1850°C and match the refractive index, and pass SiCl into the reaction tube of Φ30×2.5×500mm 4 (300mL / min), POCl 3 (30mL / m), CCl 2 f 2 (5mL / m) and O 2 (1800mL / min) reaction to generate SiO 2 ,P 2 o 5 and silicon fluoride;

[0033] (2) Deposition stress area: After the outer cladding is deposited, SiCl is introduced 4 (220mL / min), BBr 3 (400mL / min) and O 2 (1800mL / min), react at a temperature of 1800°C to form SiO 2 and B 2 o 3Deposited on the inner surface of the outer cladding obtained in step (1), forming an annular stress zone with a circular cross section;

[0034] (3) Deposit inner cladding: control the refractive index to be matched, and introduce SiCl 4 (300mL / min), POCl 3 (40mL / min), CCl 2 f 2 (5mL / min) and O 2 (1800mL / mi...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, the difference is that the GeCl of 5mL / min is also passed into step (2) simultaneously. 4 , the reaction product is SiO 2 , B 2 o 3 and GeO 2 A mixture of refractive index and outer cladding SiO 2 The refractive index is equal.

Embodiment 3

[0042] This embodiment is basically the same as Embodiment 1, the difference is that the MCVD process system used in this embodiment has special equipment for gas phase doping, and step (4) is to mix SiCl 4 (300mL / min), GeCl 4 (30mL / min) and O 2 (1800mL / min) at a temperature of 1850°C to generate SiO 2 and GeO 2 , deposited inside the inner cladding to form a core, and then shrunk into an optical fiber preform at a temperature of 1900°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com