Engineering machine balancing rocker arm chassis travelling device

A technology of construction machinery and walking devices, which is applied in transportation and packaging, fluid steering mechanisms, elastic suspensions, etc. It can solve the problems of difficulty in meeting the requirements of passability and stability at the same time, complex structure and driving form, complex and heavy chassis structure, etc. problems, to achieve the effect of improving stable operation ability, improving ride comfort and passability, and preventing rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

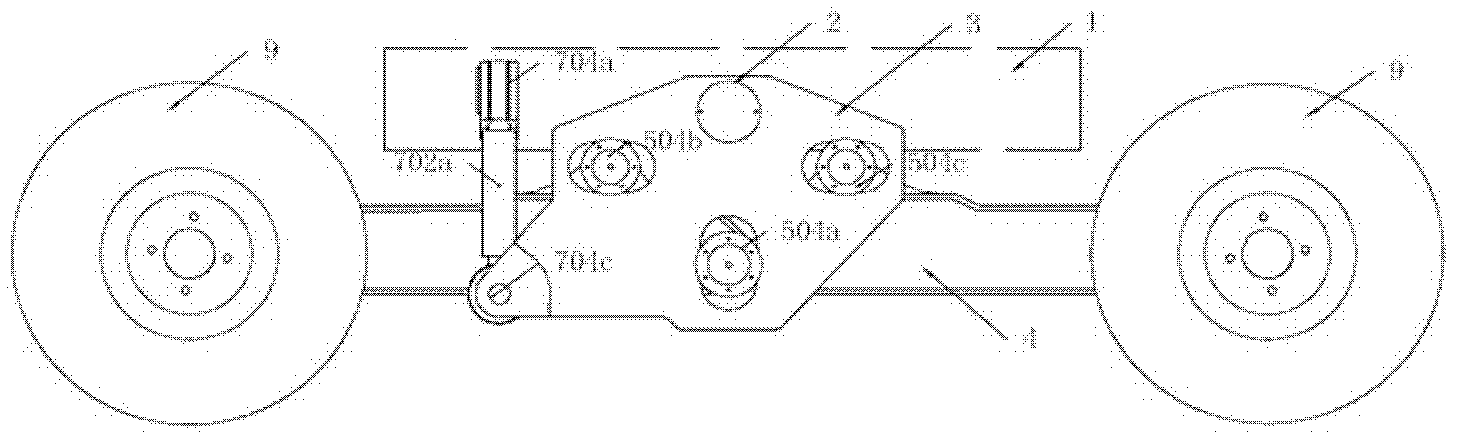

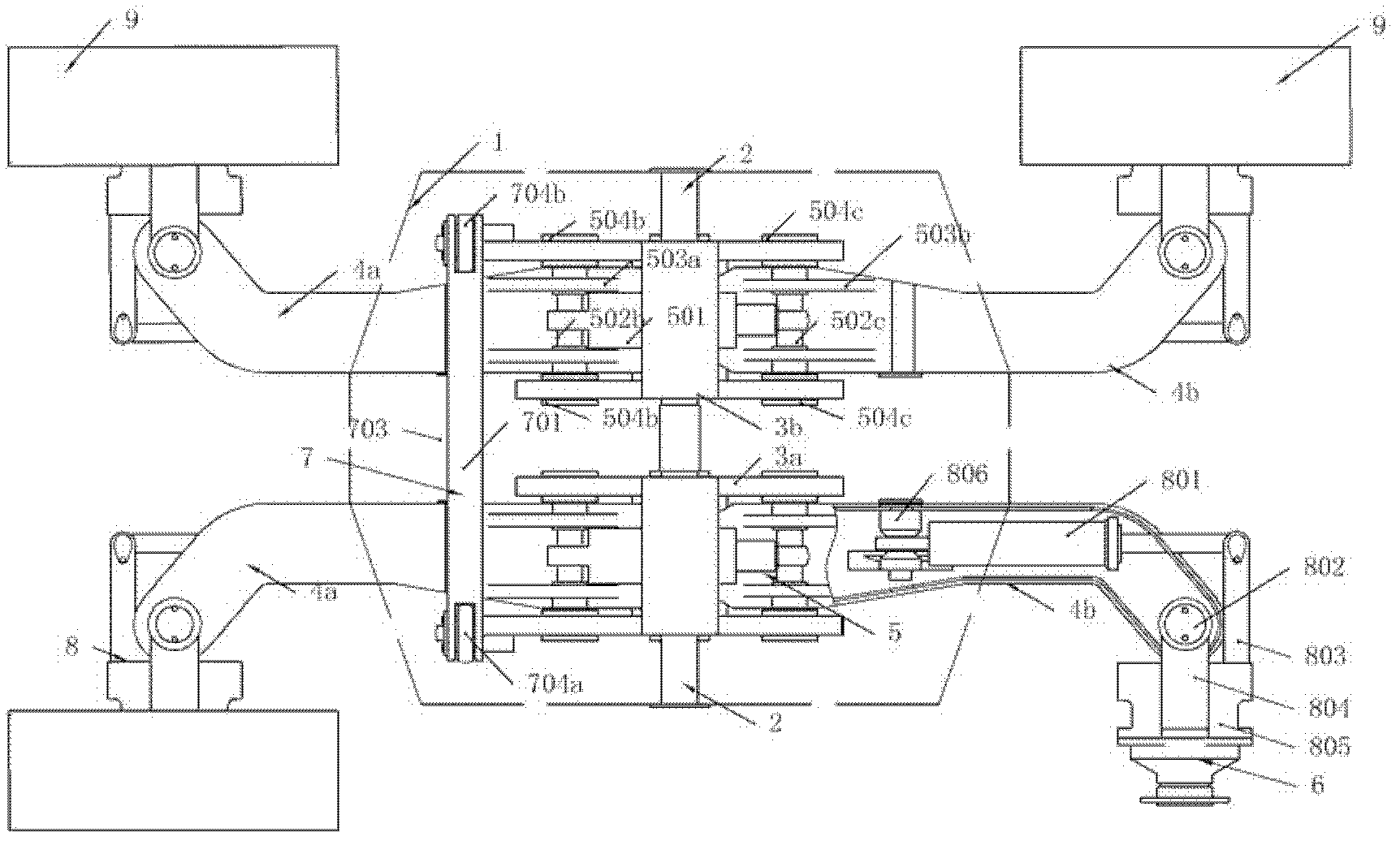

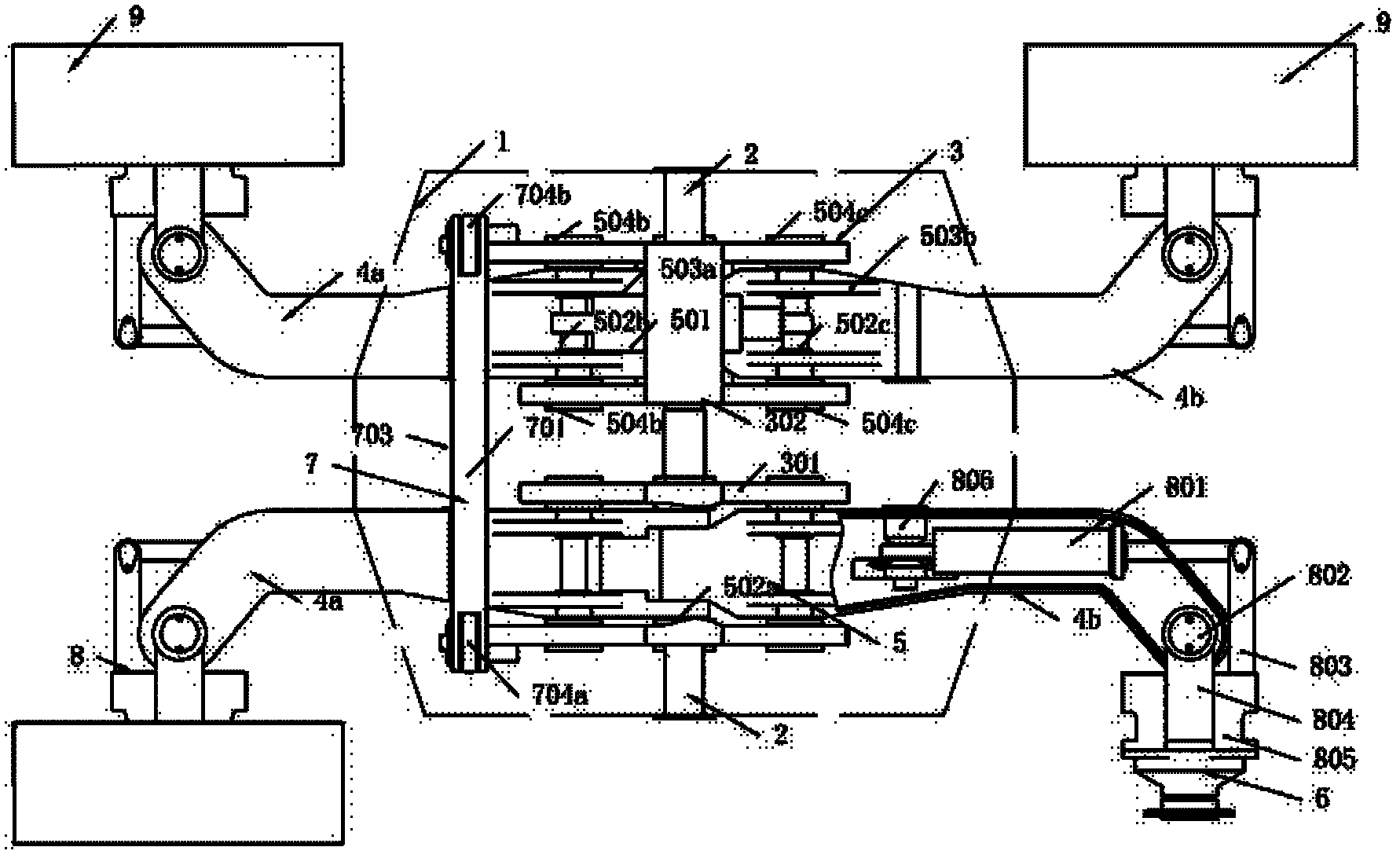

[0047] See figure 1 , figure 2 , the present invention is a kind of engineering machinery balanced rocker chassis traveling device, and it is made up of vehicle frame 1, middle main shaft 2, rocker frame 3, rocker arm 4, ground gap adjustment mechanism 5, travel motor and braking device 6, balance mechanism 7. Steering device 8, wheels 9 and other parts.

[0048] Such as figure 1 , figure 2 , as shown, the frame 1 is arranged on the rocker arm frame 3 through the intermediate spindle 2 and the balance mechanism 7, the rocker arm frame 3 is connected with the rocker arm 4 through a group of ground clearance adjustment mechanisms 5, and the front end of the rocker arm 4 is connected to the steering device 8. The steering device 8 is connected with the travel motor and the braking device 6 through bolts, and is connected with the wheels 9 through bolts.

[0049] Such as Figure 8 , 10 As shown, the vehicle frame 1 is a complex box structure welded by steel plates, mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com