H-type power chassis with function of adjusting ground clearance and wheel tread

A power chassis and chassis technology, which is applied in the field of vehicle engineering, can solve the problems of easy slippage of driving wheels, inability of vehicles to travel, and complex all-wheel drive structure, so as to improve ride comfort and passability, improve passing performance, and improve road conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

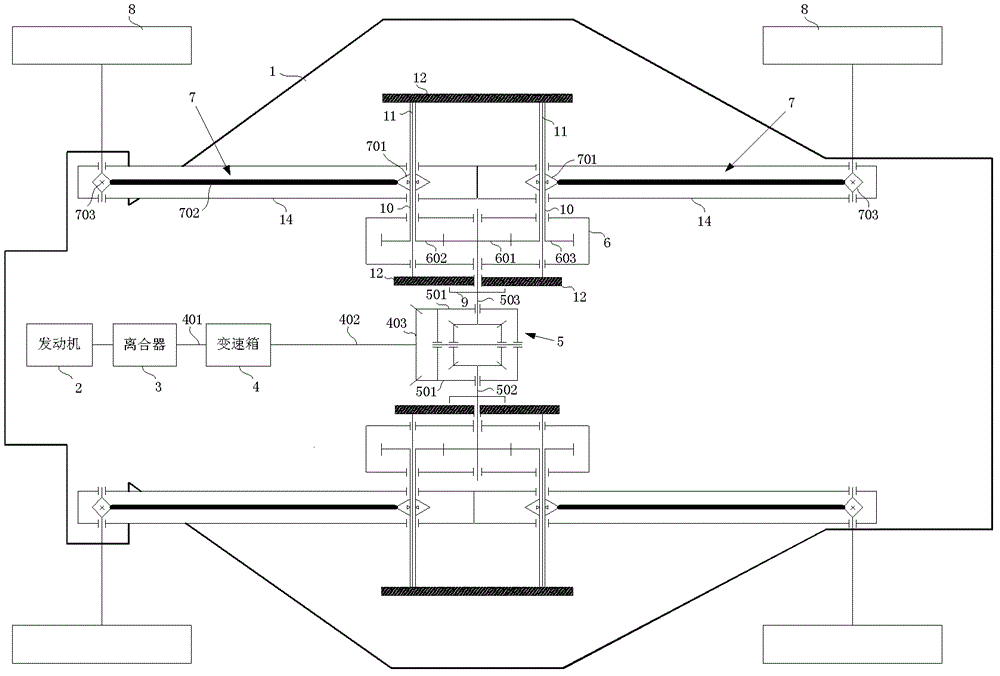

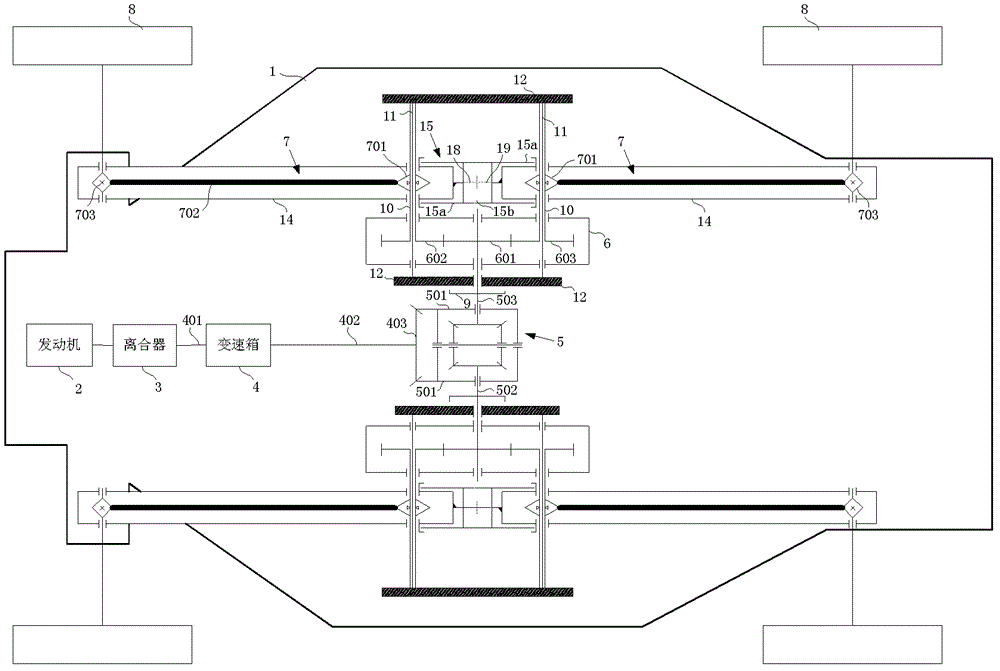

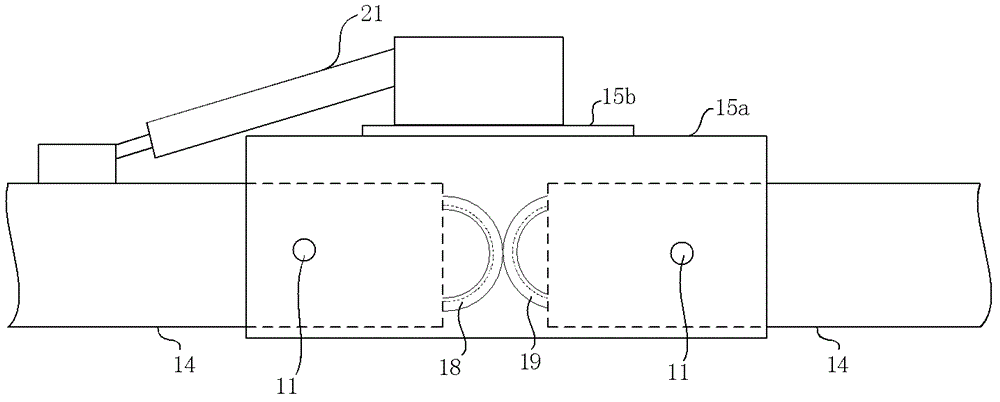

[0037] A kind of H type power chassis of the present invention, comprises chassis 1 and the engine 2 that is arranged on chassis 1, clutch 3, gearbox 4, differential gear 5, transfer case 6, sprocket transmission mechanism 7 and wheel 8, as figure 1 shown. Its transmission route is: engine 2-gearbox 4-differential 5-transfer case 6-sprocket transmission mechanism 7-wheel 8.

[0038] Wherein, the engine 2 is located at the front portion of the chassis 1, the engine 2 is connected with the clutch 3, the clutch 3 is connected with the input shaft 401 of the gearbox 4, and the driven bevel gear 403 and the differential 5 are driven on the output shaft 402 of the gearbox 4. The bevel gear 501 meshes. The engine 2 sends power to the differential 5 after passing through the gearbox 4 . The clutch 3 is used to temporarily separate and gradually engage the engine 2 and the gearbox 4 to cut off or transmit the power input from the engine 2 to the gearbox 4 . The left output shaft 502...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com