H-shaped power chassis

A power chassis and chassis technology, applied in the field of vehicle engineering, can solve the problems of easy slippage of driving wheels, complex all-wheel drive structure, easy rollover, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

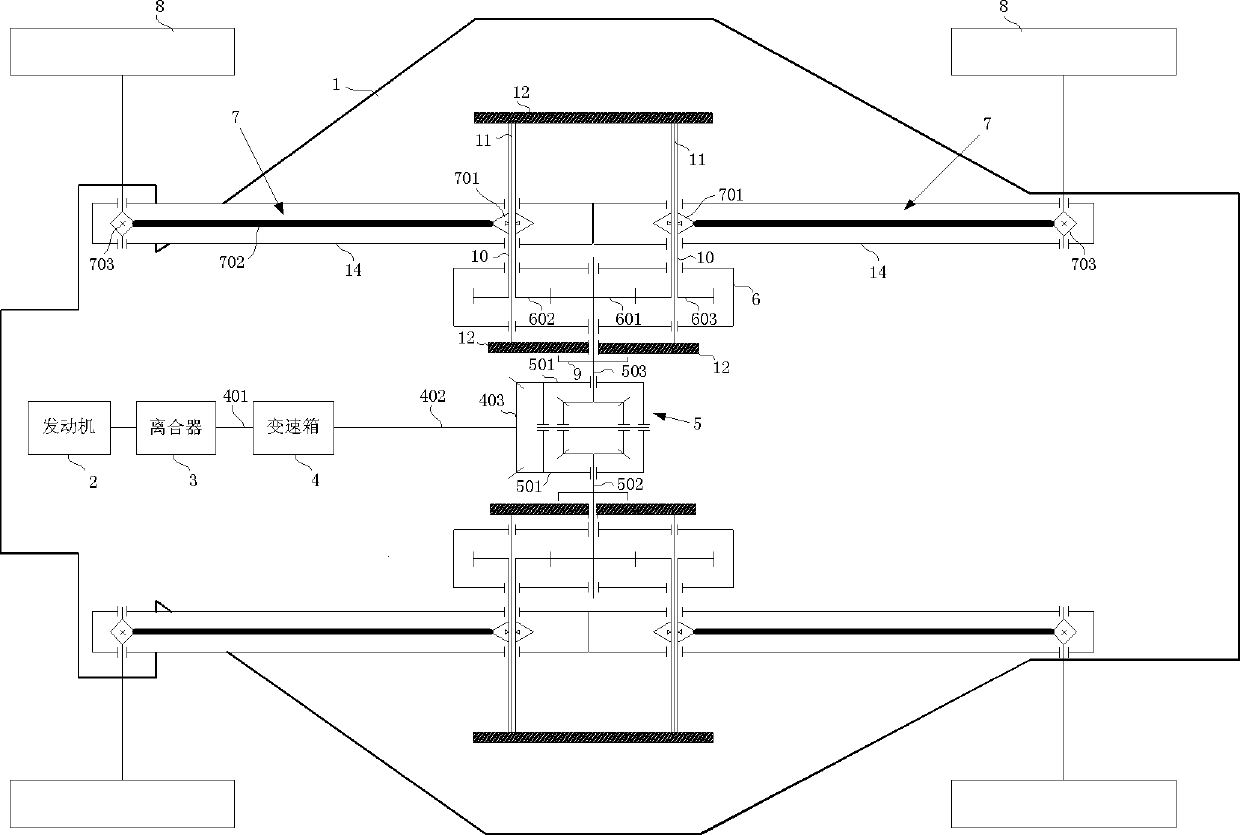

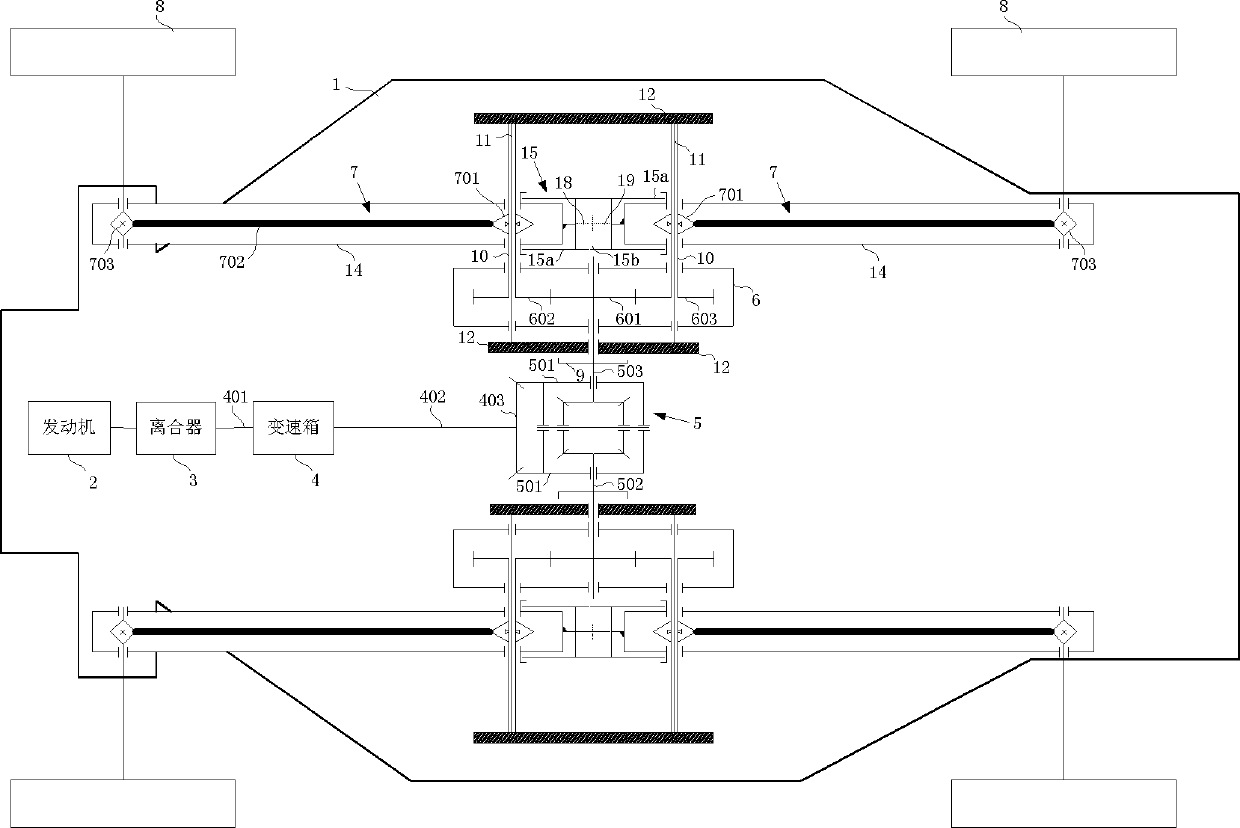

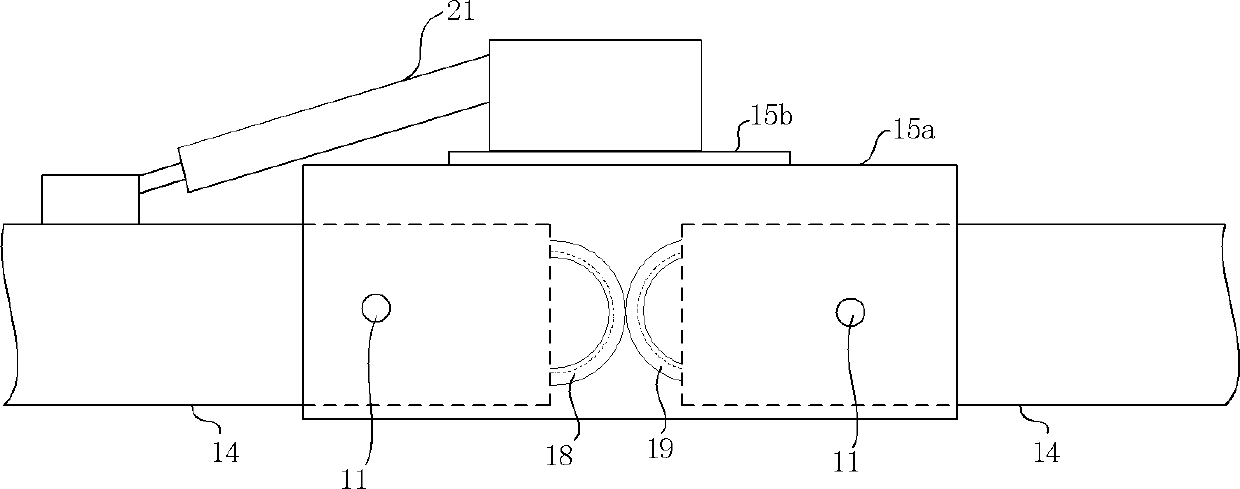

[0038] A kind of H type power chassis of the present invention, comprises chassis 1 and the engine 2 that is arranged on chassis 1, clutch 3, gearbox 4, differential gear 5, transfer case 6, sprocket transmission mechanism 7 and wheel 8, as figure 1 shown. Its transmission route is: engine 2—gearbox 4—differential 5—transfer case 6—sprocket drive mechanism 7—wheel 8.

[0039] Wherein, the engine 2 is located at the front portion of the chassis 1, the engine 2 is connected with the clutch 3, the clutch 3 is connected with the input shaft 401 of the gearbox 4, and the driven bevel gear 403 and the differential 5 are driven on the output shaft 402 of the gearbox 4. The bevel gear 501 meshes. The engine 2 sends power to the differential 5 after passing through the gearbox 4 . The clutch 3 is used to temporarily separate and gradually engage the engine 2 and the gearbox 4 to cut off or transmit the power input from the engine 2 to the gearbox 4 . The left output shaft 502 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com