Coil replacing mechanism

A swing mechanism and frame technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of increasing production costs, increasing production processes, and waste of sheets, so as to reduce production costs and reduce production Process, the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

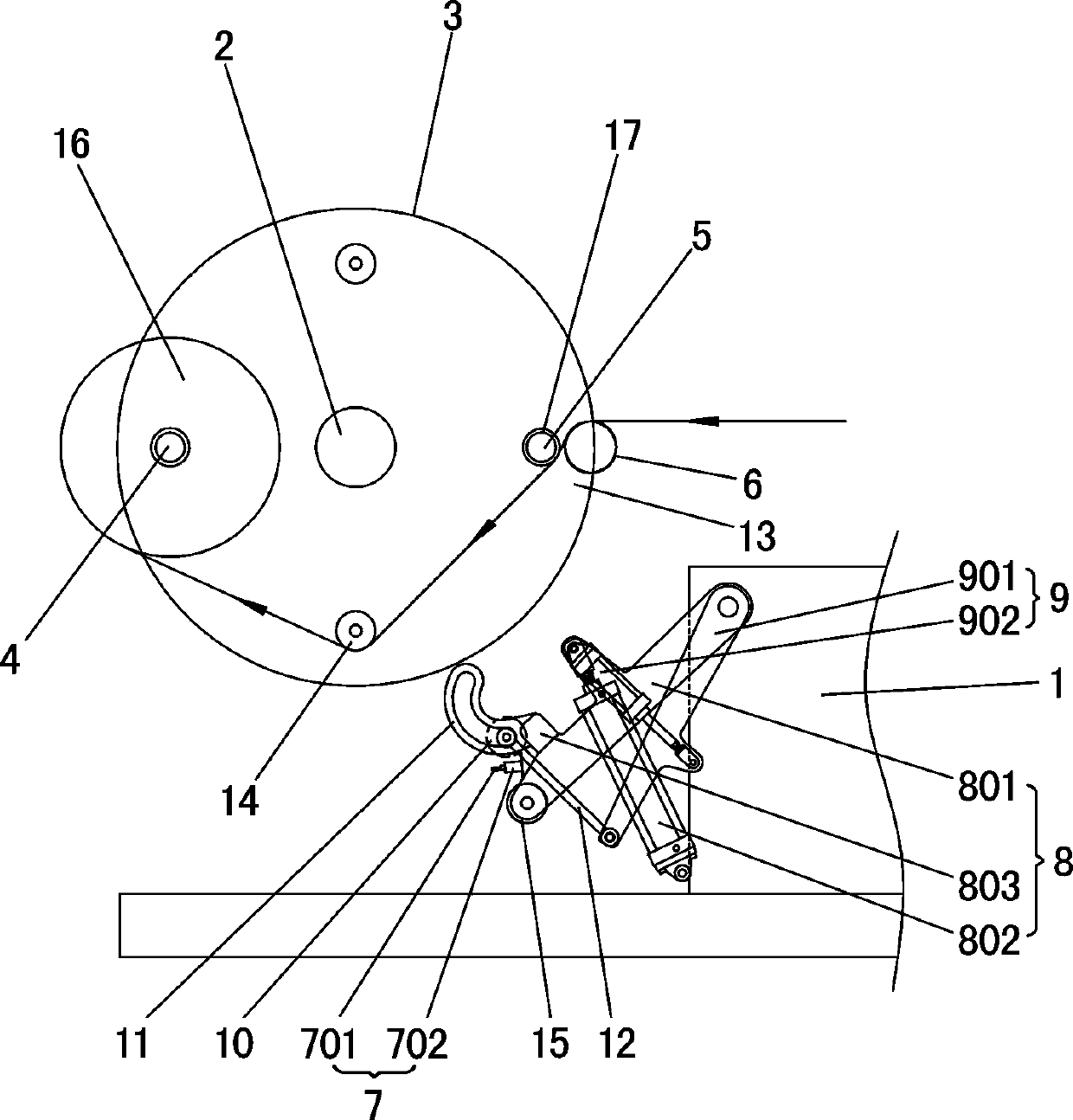

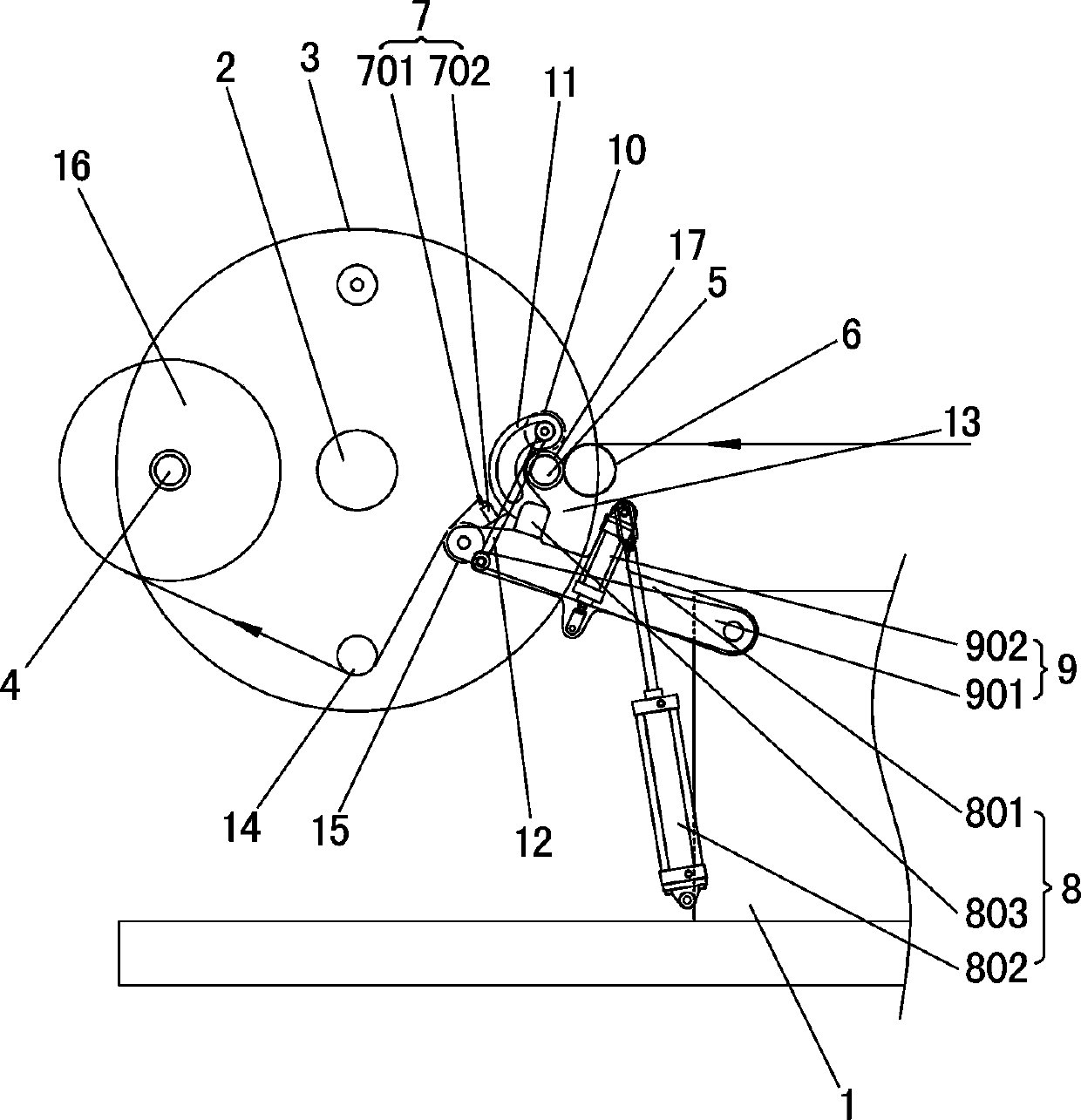

[0018] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0019] like figure 1 As shown, this roll changing mechanism includes a frame 1, a rotating shaft 2, two central turntables 3, a first reel 4, a second reel 5, a pressure roller 6, a cutter device 7, a first swing mechanism 8, a second Swing mechanism 9, pasting roller 10, two arc-shaped chutes 11 and connecting rod 12; rotating shaft 2 is rotatably installed on the frame 1, and two central rotating disks 3 are respectively installed at the two ends of rotating shaft 2; the first reel 4, The two ends of the second reel 5 are respectively rotatably mounted on the two central turntables 3, and the first reel 4 and the second reel 5 are symmetrically distributed on both sides of the rotating shaft 2; the frame 1 is provided with a chute, the position of the chute Corresponding to the first station 13, the two ends of the pressure rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com