Roof regeneration medium-length hole ore blast backfill mining method

A backfill mining method and roof technology, which are applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of difficult implementation of roof protection technology, high cutting ratio per thousand tons, high cost, and achieve safe and reliable mining environment. The effect of dilution control and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

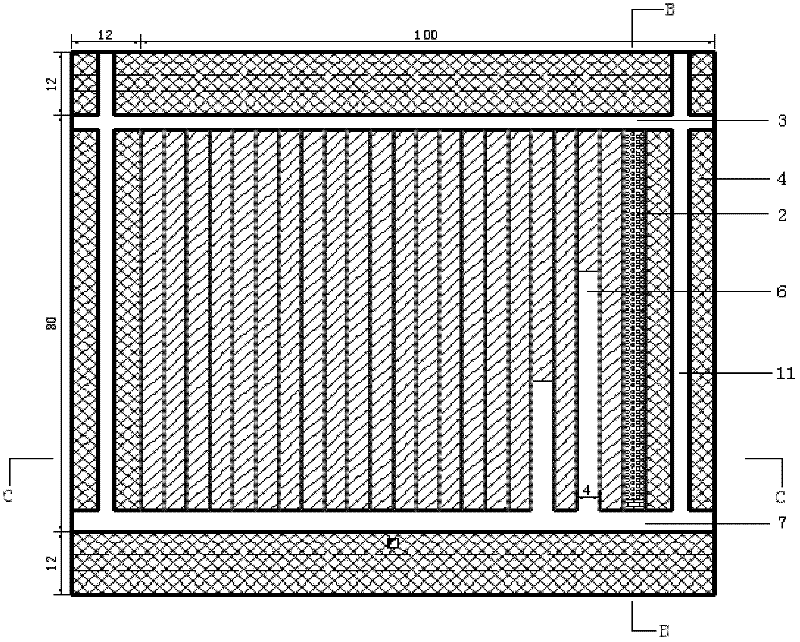

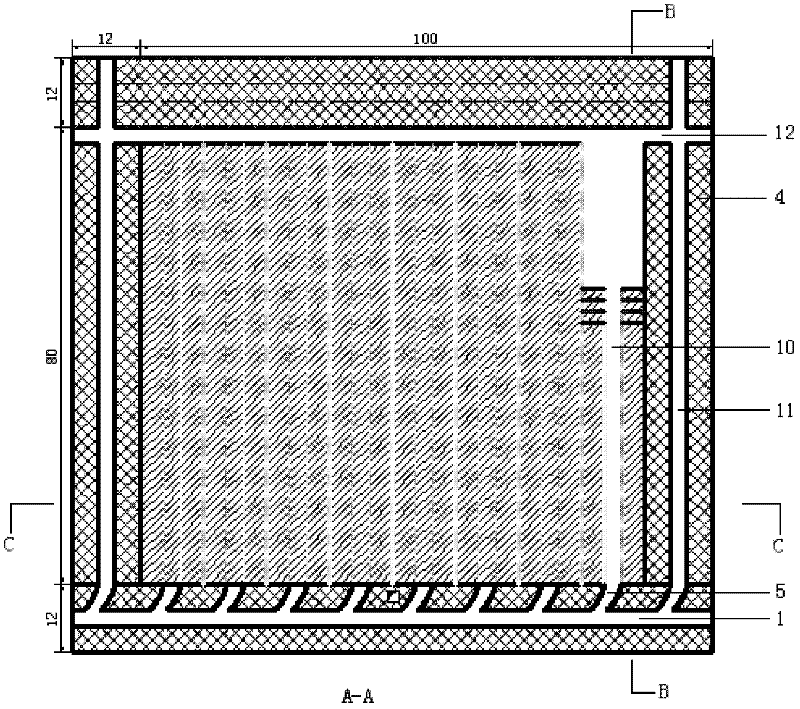

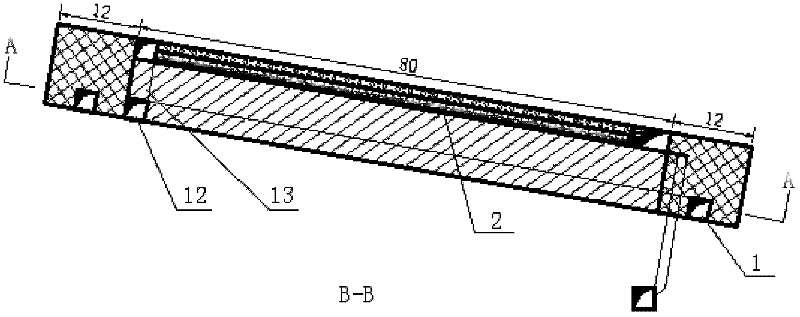

[0023] The present invention will be further elaborated below in conjunction with accompanying drawing:

[0024] (1) Divide the ore body into the middle section, leave a 12m continuous ore pillar along the trend in the middle, and then divide the ore body into panels through the inter-panel pillar 4 along the dip. The inter-panel pillar 4 is 12m wide and 80m long along the dip. The strike length is 100m, and the panel area is divided into several stopes along the strike;

[0025] (2) Arrange the main access road 1 of the scraper along the strike at the bottom plate of the continuous ore pillar, with a size of 3m×3m, communicate with each stope through the stope connecting road 5, and communicate with the ramp at one end of the ore body; 4 The position of the bottom plate is arranged along the inclination of the branch route 11 of the scraper, with a size of 3m×3m, which is used as a channel to communicate with each middle section; at the position of the top plate at the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com