Rod end joint bearing

A rod end joint bearing and rod end technology, applied in the field of mechanical parts, can solve problems such as short gap life, achieve product quality improvement, novel structure, and increase the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

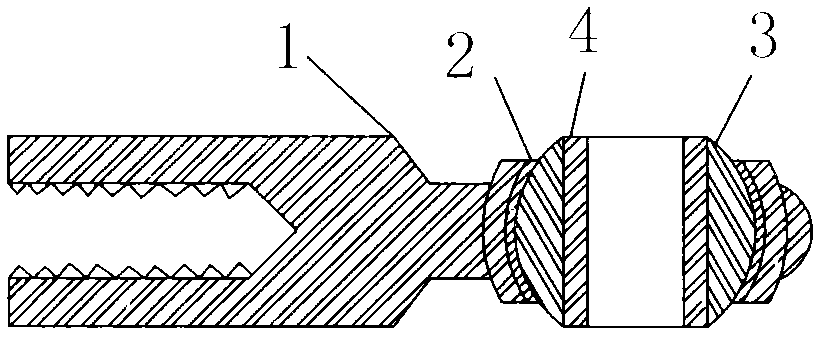

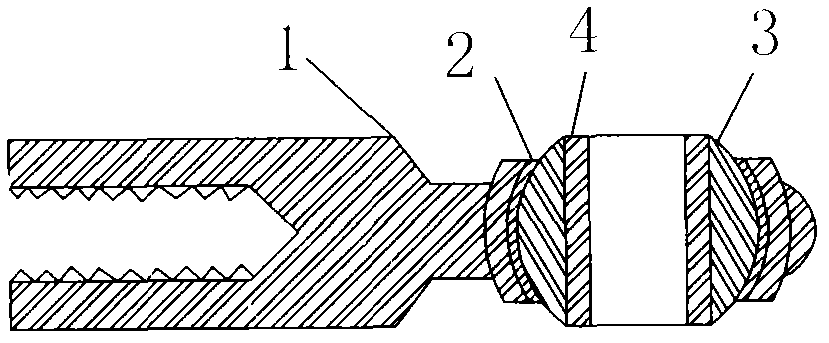

[0014] Such as figure 1 As shown, a rod end joint bearing includes a rod end housing 1, a self-lubricating cushion layer 2, a perforated ball 3, and a perforated shaft 4, wherein the perforated ball 3 is arranged in the rod end housing 1, and the self-lubricating The lubricating cushion layer 2 is arranged between the perforated ball 3 and the rod end housing 1, and the perforated shaft 4 is arranged in the hole of the perforated ball 3.

[0015] In the rod end joint bearing of the present invention, the perforated shaft 4 is arranged in the hole of the perforated ball 3, the perforated shaft 4 is in clearance fit with the inner hole of the perforated ball 3, and the perforated shaft 4 is in full contact with the inner hole of the perforated ball 3. When the rotation speed is increased, the perforated ball 3 and the rod end housing 1 only play a guiding role.

[0016] When the rod end joint bearing of the present invention is applied, it is only necessary to directly replace the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com