Damp-variable automobile damper with capillary tubes in parallel connection

A capillary tube and shock absorber technology, which is applied to shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problems of non-adjustable damping characteristics and small adjustable range, and achieves simple and easy technical means and low cost. , the effect of improving the quality of damping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

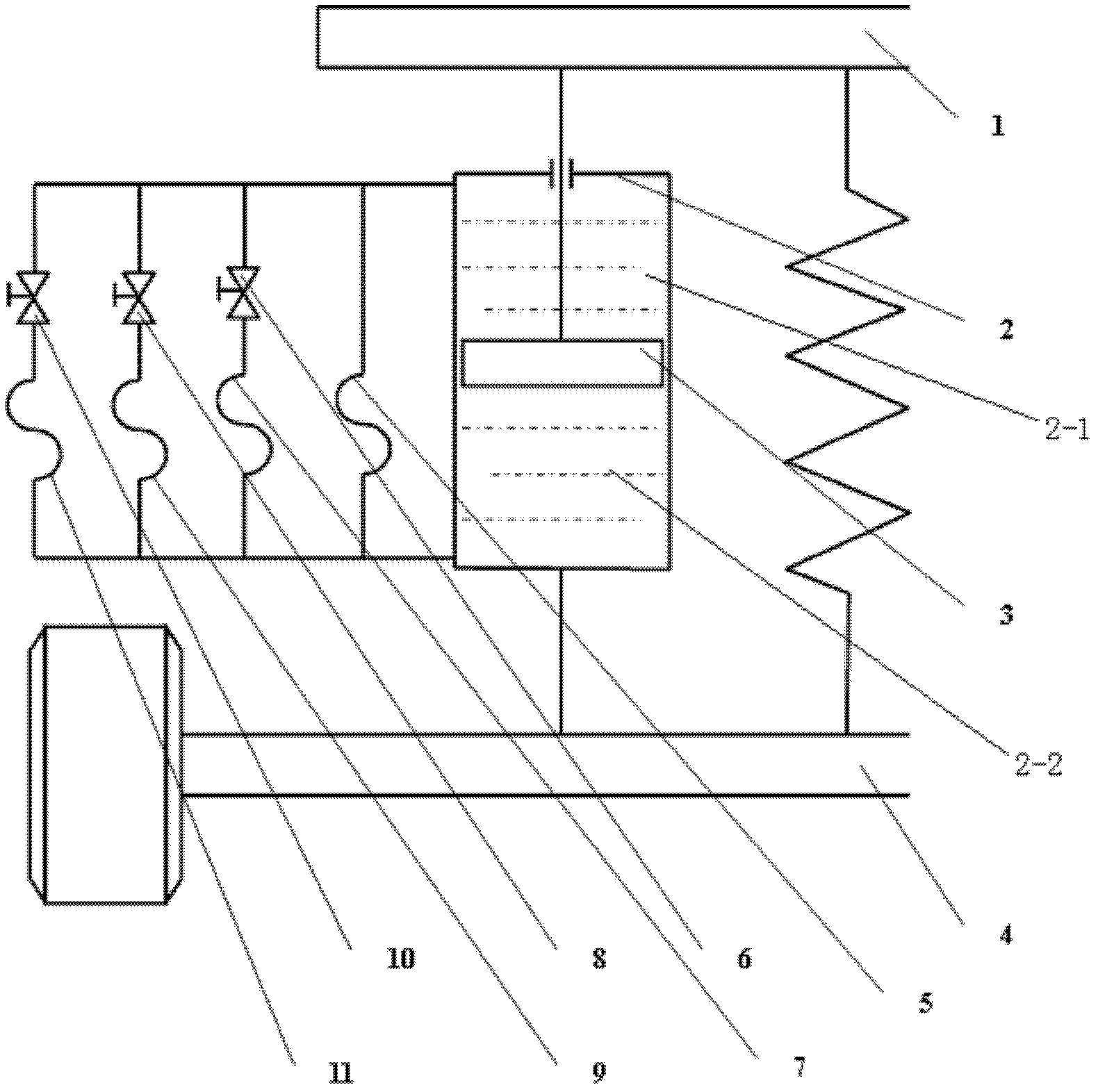

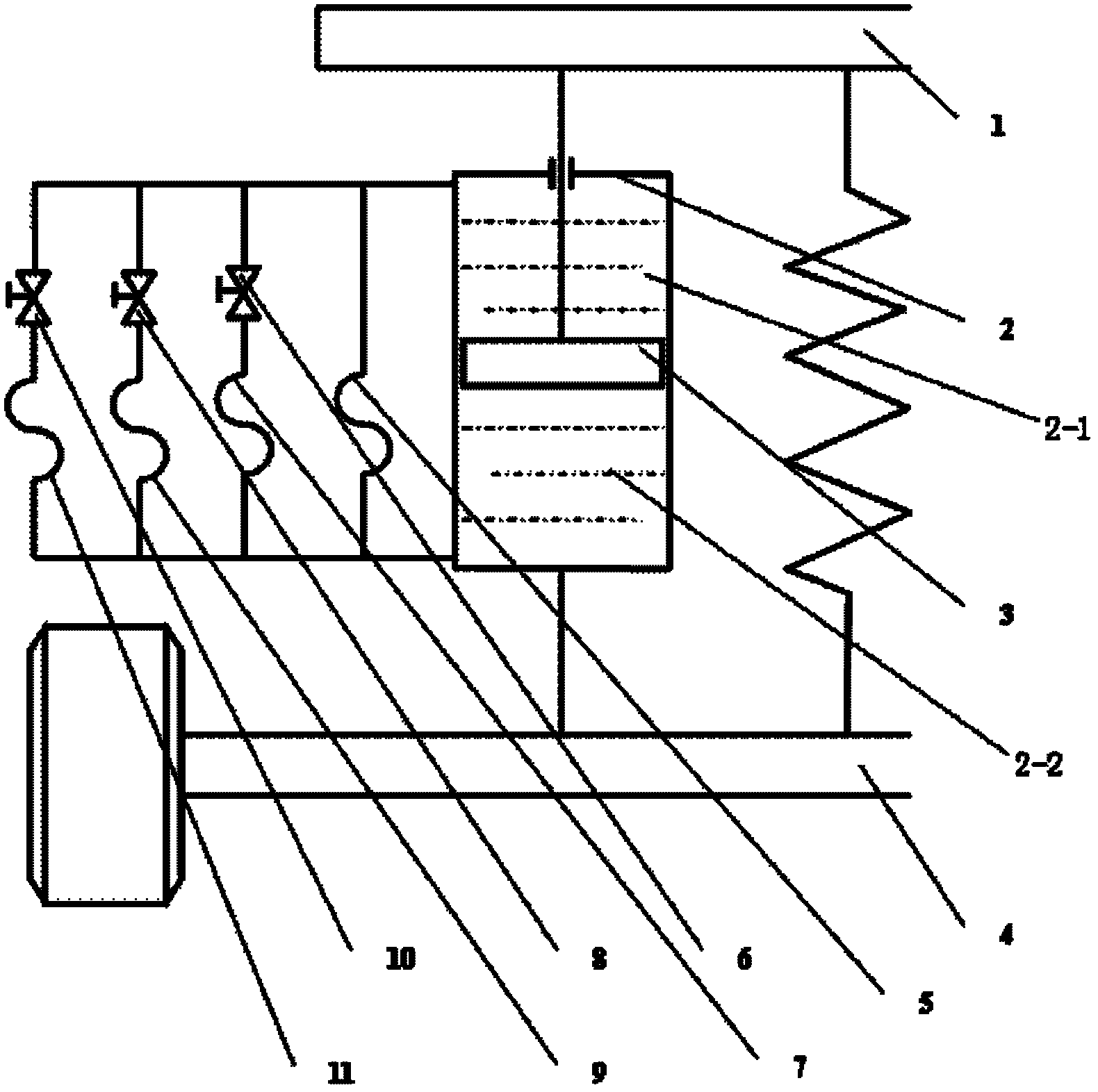

[0025] Such as figure 1 As shown, the automobile shock absorber with parallel capillary variable damping of the present invention includes a cylinder body 2 and a piston 3 placed in the cylinder body 2. The inside of the cylinder body 2 is bounded by the piston 3 and is divided into an upper oil tank 2-1 And the lower oil tank 2-2 is characterized in that it also includes a capillary group composed of four capillary tubes 5, 7, 9, 11 connected in parallel, a general port of the capillary group communicates with the upper oil tank 2-1 of the cylinder body, and the capillary tube Another total port of the group communicates with the lower oil tank 2-2 of the cylinder body.

[0026] The capillary group includes No. 1 capillary 5 , No. 2 capillary 7 , No. 3 capillary 9 and No. 4 capillary 11 . Except for No. 1 capillary 5, the remaining three capillaries 7, 9, 11 are all connected in series with a solenoid valve 6, 8, 10; wherein, No. 2 solenoid valve 6 is connected in series wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com