Equipment vibration isolation substrate

A vibration isolation and base technology, applied in mechanical equipment, special foundation layout, non-rotational vibration suppression, etc., can solve the problem of low overall height, and achieve the effect of reducing the transmission of vibration to solids and reducing the height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

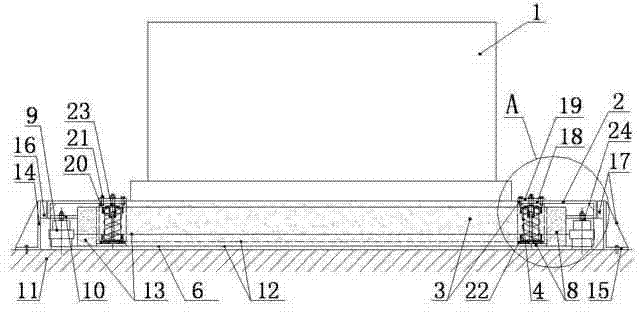

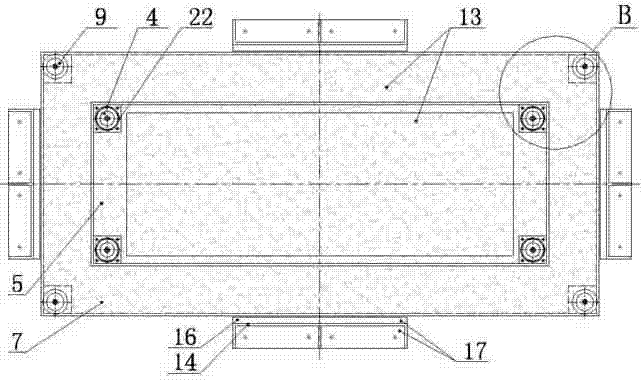

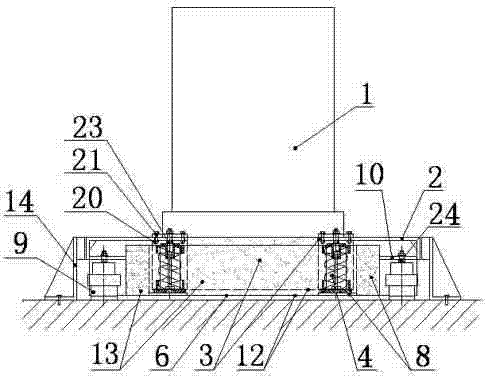

[0019] exist figure 1 , 2 , In the first embodiment shown in 3, the equipment (1) is installed on the upper vibration isolation structure (5) consisting of the upper supporting steel plate (2), the upper rigid mass (3) and the upper vibration isolator (4) , the upper vibration isolator (4) is installed between the upper support steel plate (2) and the lower support steel plate (6), and the upper rigid mass (3) of the upper vibration isolation structure (5) is embedded in the lower vibration isolation structure (7) Between the lower rigid mass (8) and the lower support steel plate (6), the lower vibration isolator (9) is installed between the middle support steel plate (10) and the floor (11) of the lower rigid mass (8). Both the upper rigid mass (3) and the lower rigid mass (8) are composed of a trough structure (12) and a counterweight (13), and vertical steel baffles (14) are arranged around the upper supporting steel plate (2). The damping limiter (17) composed of load-be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com