Detector for correcting measuring accuracy of sonic nozzle of diaphragm gas meter

A membrane gas meter and measurement accuracy technology, which is applied in the direction of instruments, measuring devices, testing/calibrating devices, etc., can solve the problems of low one-time pass rate of products, increased repeated detection process, and low work efficiency, so as to avoid signal Instability, improvement of one-time pass rate, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

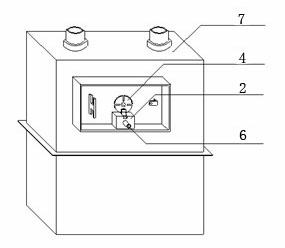

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

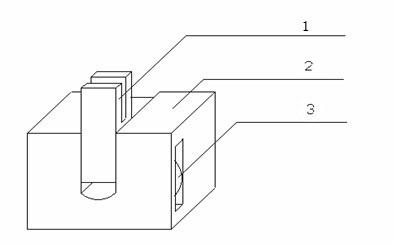

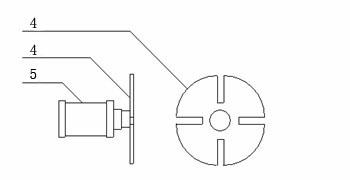

[0016] see figure 1 and figure 2 A detector for calibrating the metering accuracy of the sonic nozzle of a membrane gas meter as shown is composed of a photoelectric collector and a photoelectric encoder, and its characteristics are:

[0017] The photoelectric collector comprises a base 2, a photoelectric sensor 1 arranged in a groove of the base and a permanent magnet 3 arranged in one side of the base;

[0018] The photoelectric encoder includes a photoelectric encoder disk 4 that is matingly connected to the end of a rotating shaft and an annular magnetic steel 5 located in the middle of the rotating shaft. The edge of the photoelectric encoder disk 4 is provided with four radial strip gaps with equal distances. .

[0019] Further, the photoelectric sensor 1 is an infrared photoelectric emitting tube and an infrared photoelectric receiving tube.

[0020] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com