Concentric Wheel Piston assembly

A technology of concentric wheels and assemblies, applied in belts/chains/gears, machines/engines, mechanical equipment, etc., can solve problems such as waste of materials, large space, limited ratio difference range, etc., and achieve the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

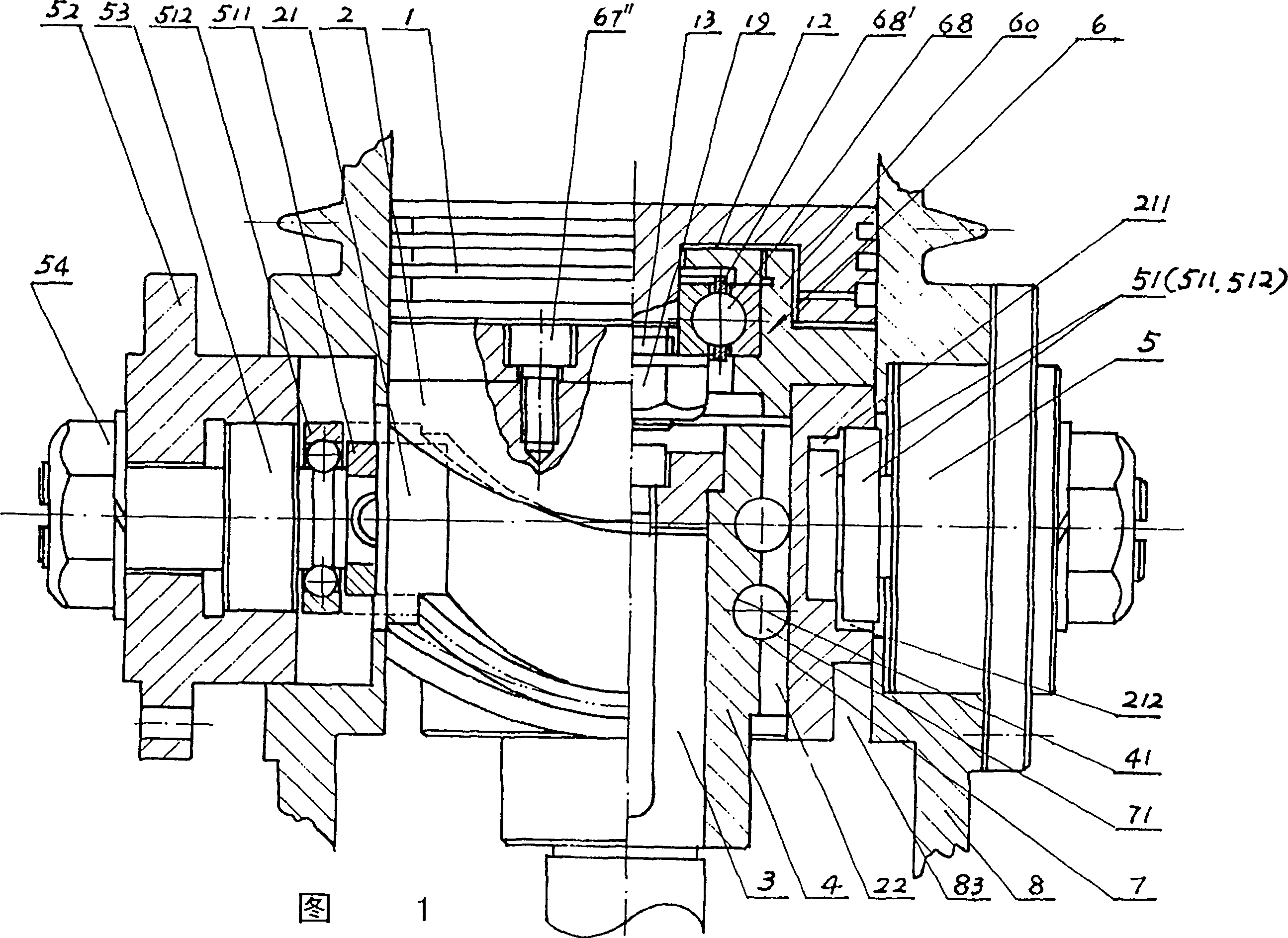

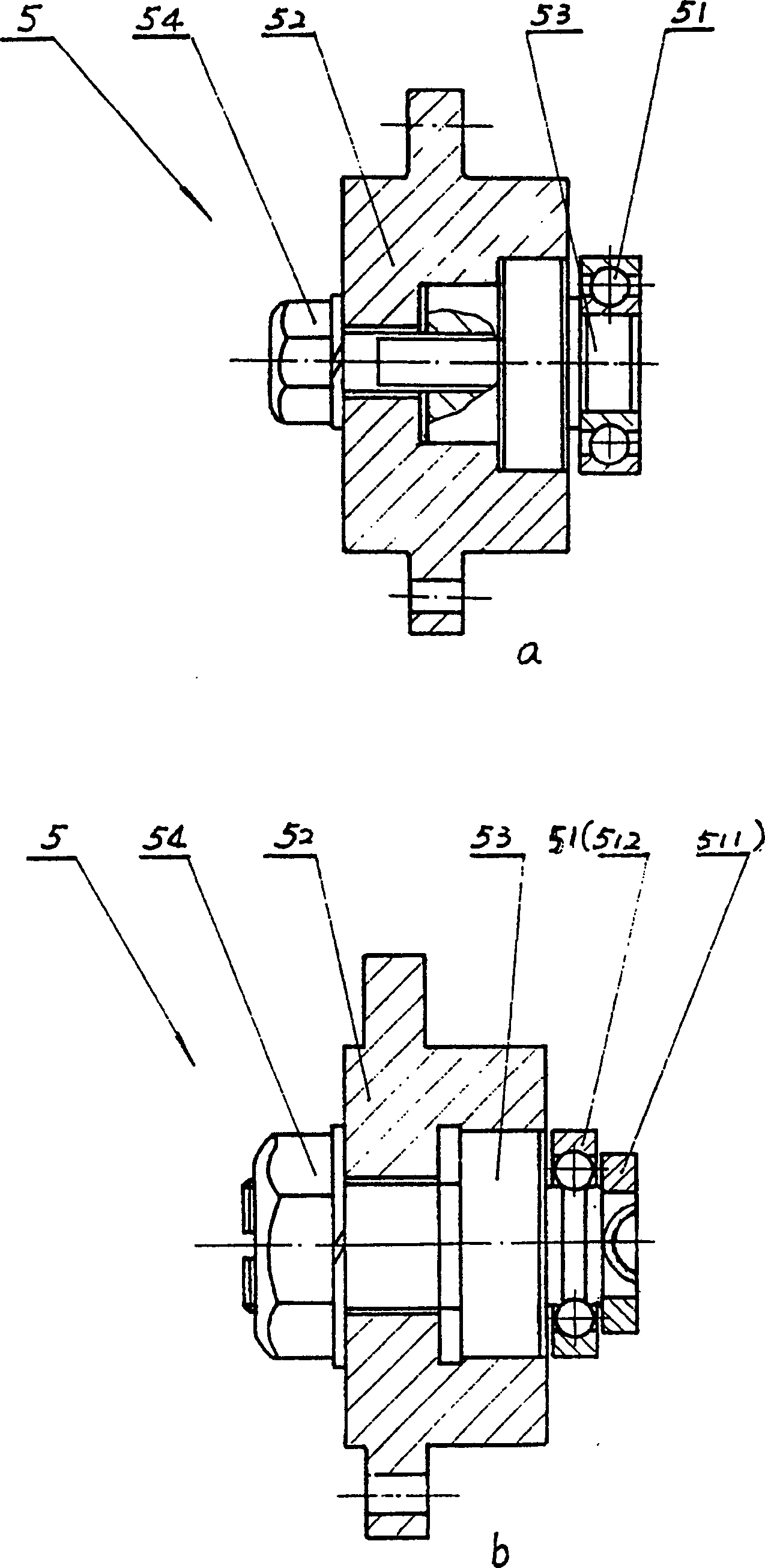

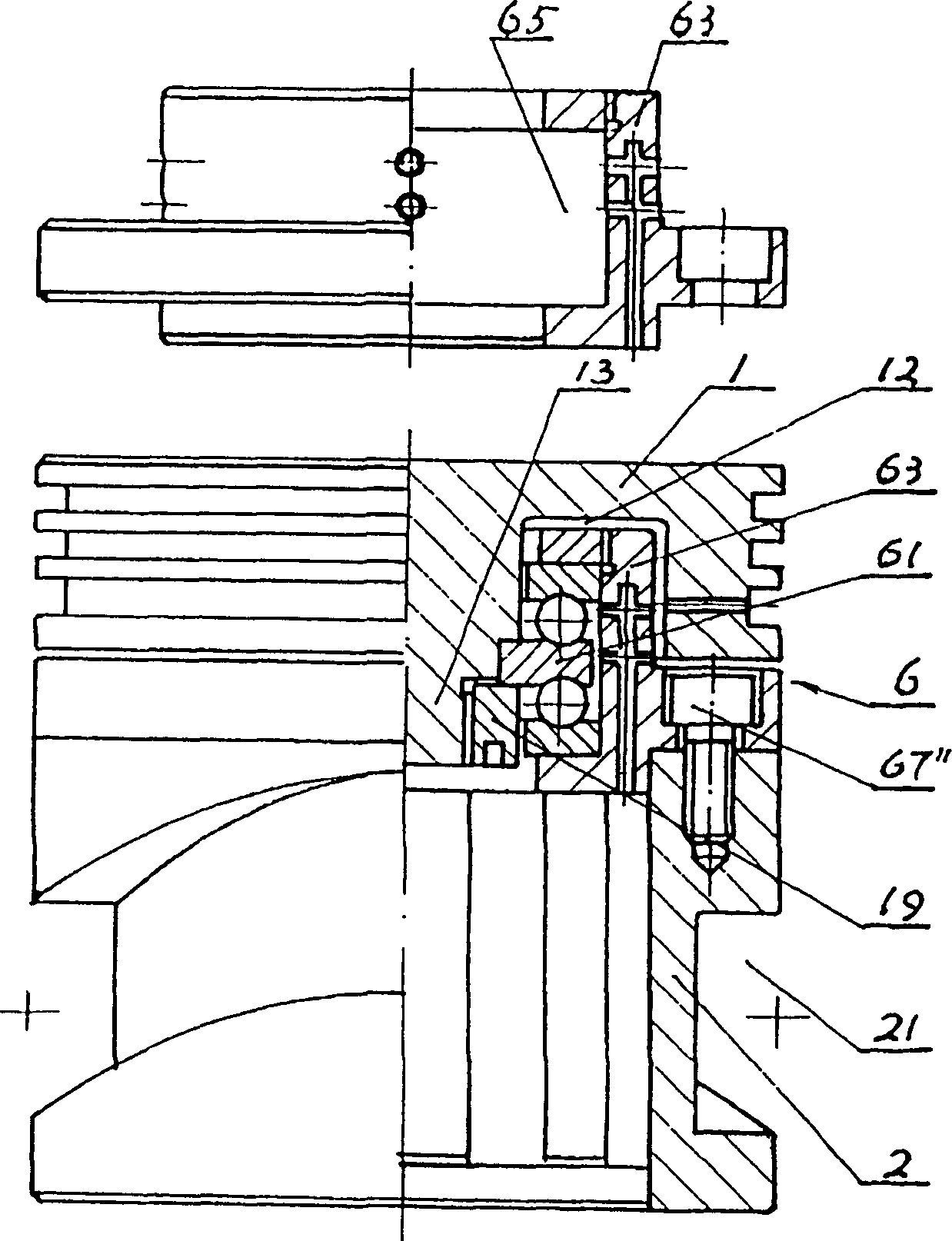

[0043] As shown in Figure 1, the concentric wheel piston assembly of the present invention comprises piston head 1, concentric wheel 2, straight shaft 3, the straight shaft wheel 4 that is detachably fixed on straight shaft 3, its bead head 51 and concentric wheel 2 The sinusoidal ball 5 engaging the peripheral chordal groove 21 , the connecting means 6 connecting the piston head 1 to the concentric wheel 2 , the movement pair 7 between the concentric wheel 2 and the straight axis wheel 4 and the housing 8 . The concentric wheel-piston assembly of the present invention also involves a sealing structure and a lubricating oil passage structure, but the content in this aspect is not within the protection scope of the present invention, so these content will not be described again.

[0044] In order to facilitate the understanding of the present invention, the positional relationship among the various parts of the concentric wheel-piston assembly of the present invention and the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com