Electrostatic induction based metal surface contact damage on-line monitoring system and monitoring method

A metal surface, electrostatic induction technology, applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., to achieve the effect of compact hardware structure and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

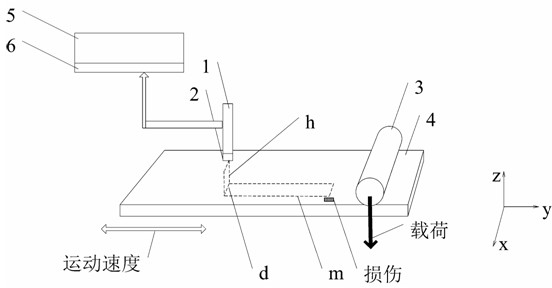

[0043] The specific implementation of the system is introduced as follows in conjunction with the accompanying drawings:

[0044] 1. The composition of the system is as figure 1 As shown, it consists of electrostatic sensor (including: electrostatic induction head 2, shielding cover 8, insulating part 10, charge amplification circuit 9), signal acquisition and analysis system (including: computer and signal processing program 5, signal conditioning acquisition hardware 6), and sensor The installation frame 7 and other auxiliary parts are composed, and the signal acquisition card in the acquisition hardware adopts NI company WLS9234 digital acquisition card, and the computer adopts a general-purpose PC based on the windows platform.

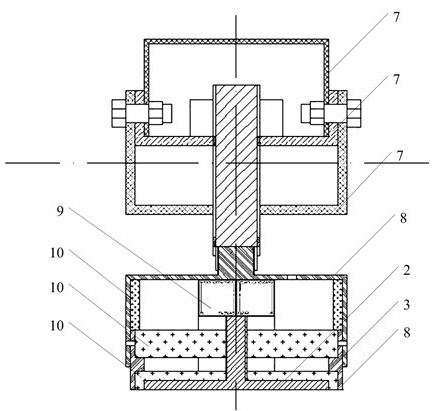

[0045] The sensor is the core device of the system. The structure of the sensor is as follows: figure 2It is composed of an electrostatic induction head 2, a shielding cover 8, an insulating part 10, and a charge amplification circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com