Wall-embedded mounting system for operation panel

A technology of operation panel and installation system, which is applied in the direction of support structure installation, cabinet/cabinet/drawer parts, etc., which can solve the problems of inconvenient maintenance, poor coordination, and troublesome operation of the locking structure, and achieve an overall appearance Beautiful and compact, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

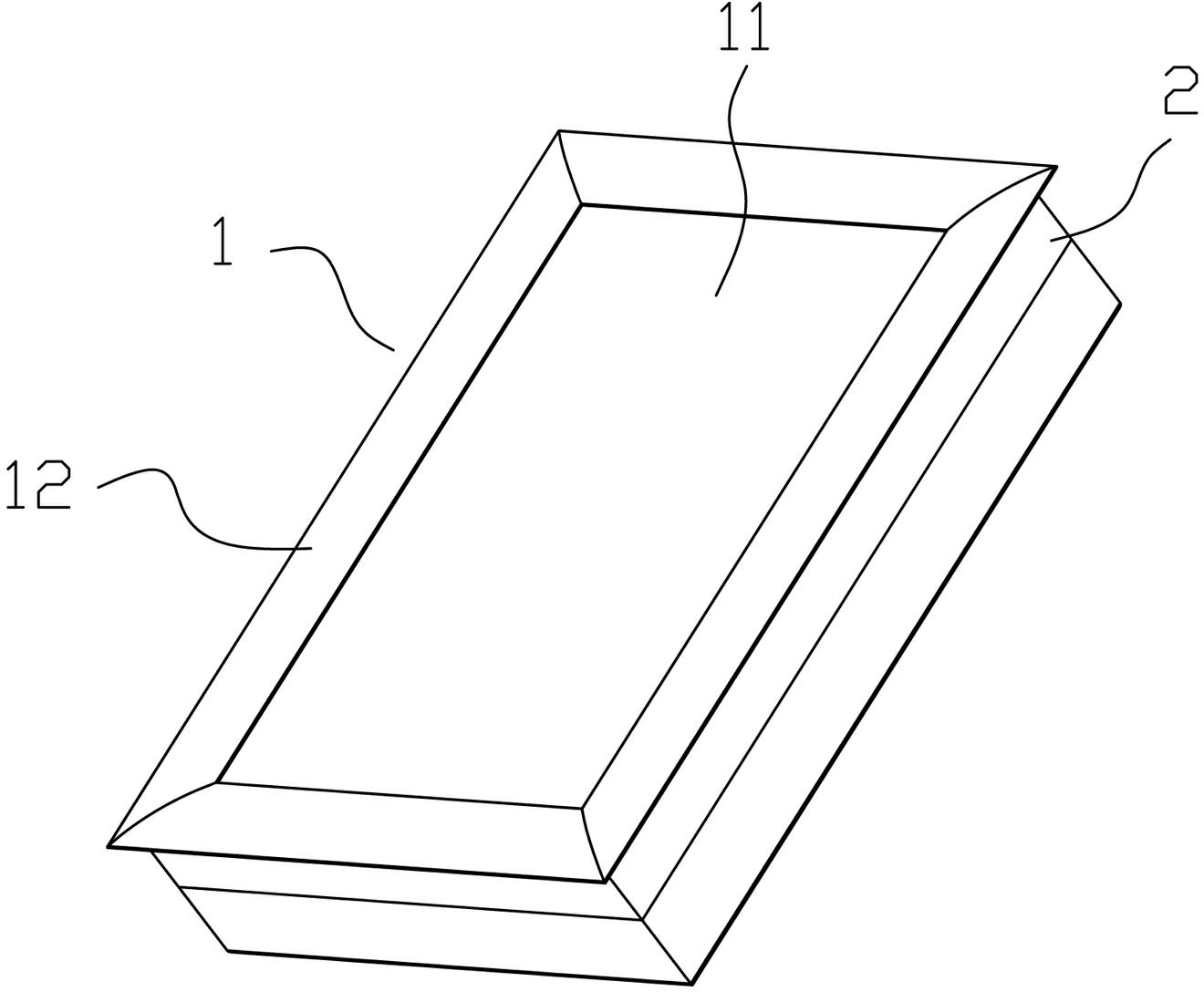

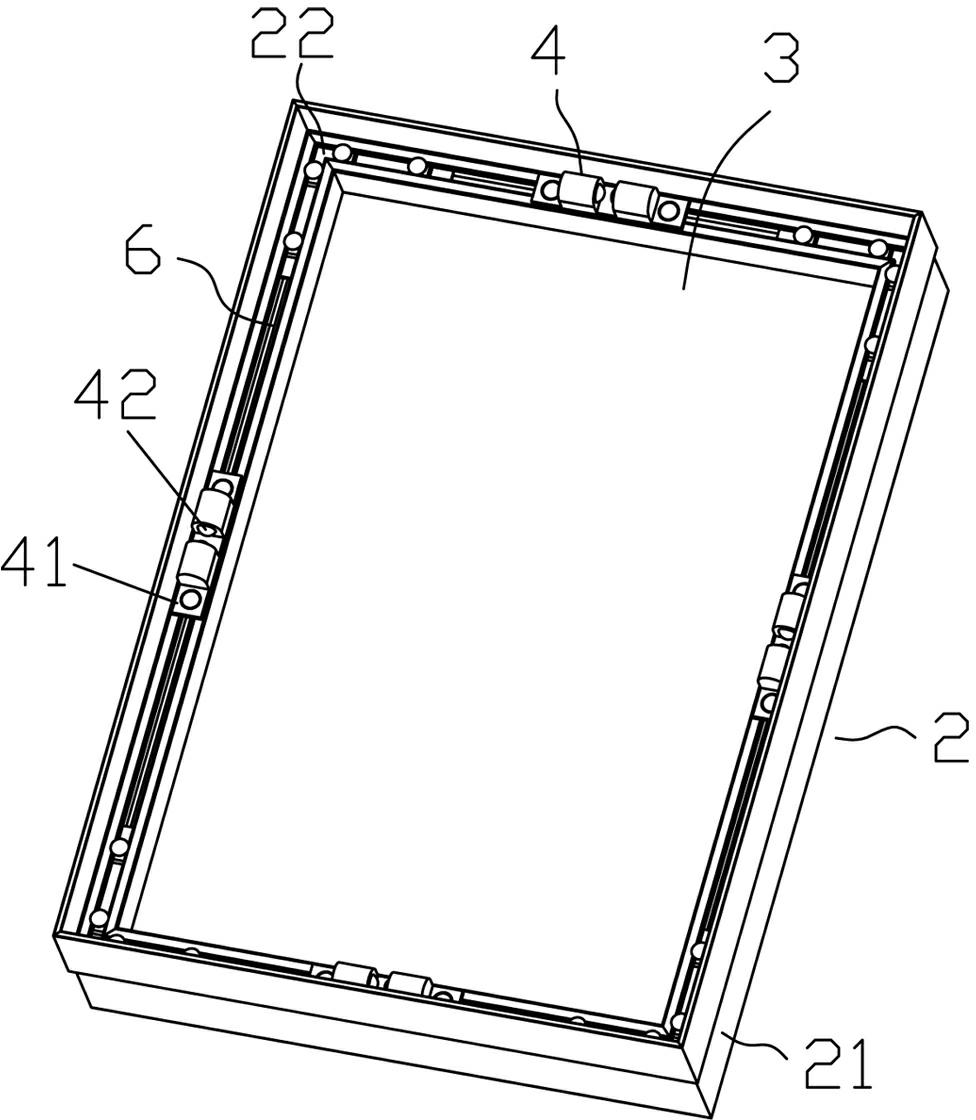

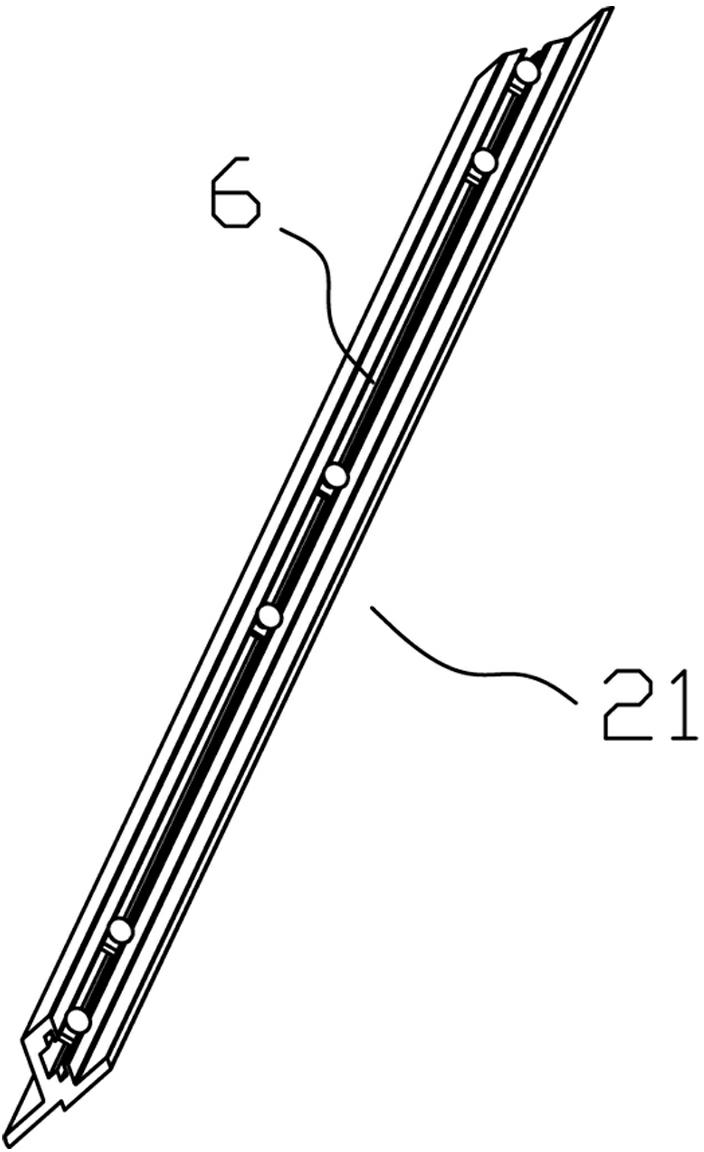

[0021] refer to Figure 1 to Figure 4 , an operation panel wall-mounted installation system of the present invention, including a panel module 1, a pre-installed frame 2 for being embedded in a wall, and an installation chamber 3, and the side of the pre-installed frame 2 facing the panel module 1 is fixedly distributed There are several clamping female seats 4, and the position corresponding to the clamping female seat 4 on the panel module 1 is fixed with a clamping male seat 5. The structure is clamped on the pre-installation frame 2, the installation chamber 3 is set under the pre-installation frame 2, and the electronic components of the operation panel are installed in the cavity formed by the panel module 1, the pre-installation frame 2 and the installation chamber 3. When the present invention is realized, the quantity of the clamping female seat 4 on the pre-installed frame 2 and the clamping male seat 4 on the panel module 1 can be flexibly set according to needs, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com