Device for pre-tensioning a machine frame, machine frame and press and pull device

A tensioning device and frame technology, applied in the field of head and shoulders, can solve the problems of troublesome and difficult assembly of the press frame on site, and achieve the effects of simplifying assembly and/or maintenance work, simple structure, and realizing processing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

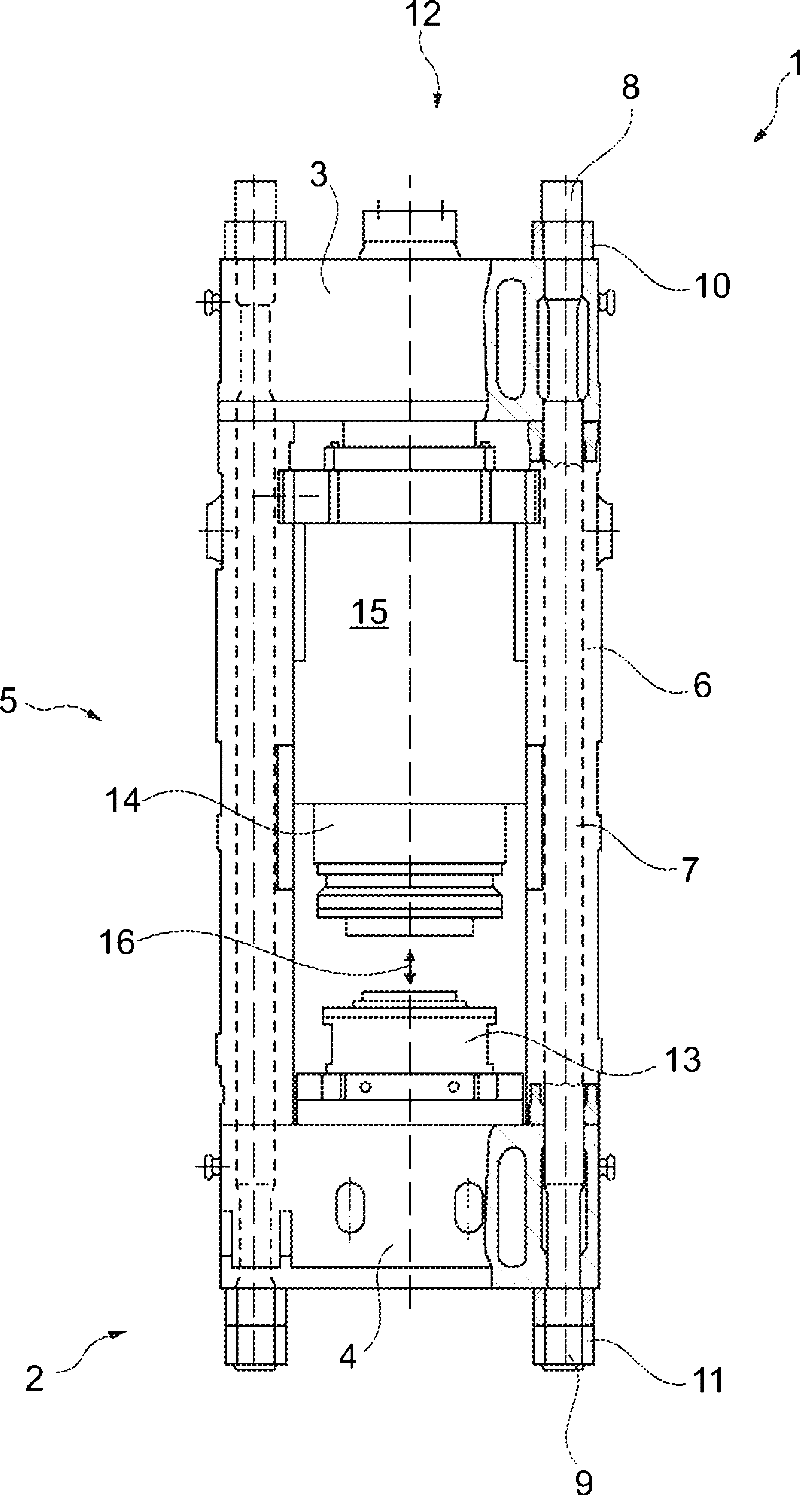

[0116] exist figure 1 The press 1 shown in has generally known press frame 2 structure by prior art, and it mainly comprises cylinder beam 3 and countertop beam 4, and the bracket mechanism 5 that is made up of four individual pressure struts 6 (in shown here as an example only). A respective tie rod 7 made of steel is arranged inside each pressure strut 6 . Each tie rod 7 protrudes not only from the cylinder beam 3 but also from the counter beam 4 on the outside, so that the respective ends 8 and 9 of the tie rods 7 can be screwed with a lock nut 10 or 11 (shown as an example here). ). The pressure struts 6 space the cylinder beam 3 and the bearing crosshead 4 from one another, while the press frame 2 as a whole is prestressed by means of tie rods 7 . This is achieved by tightening the two union nuts 10 and 11 of the respective tie rods 7 , whereby the component parts cylinder beam 3 , support crosshead 4 and pressure strut 6 are pressed against one another and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com