Fully-automatic multi-functional multi-mode integral bag making machine

A multi-functional, multi-format technology, applied in container manufacturing machinery, paper/cardboard containers, containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

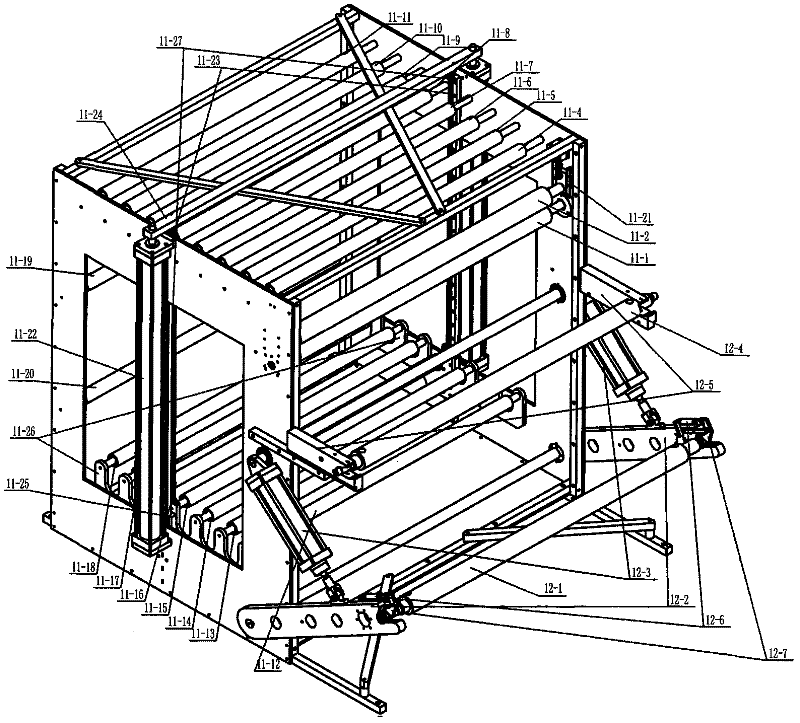

[0300] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the fully automatic multi-functional multi-system integrated bag-making machine proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , structure, feature and effect thereof, detailed description is as follows.

[0301] see Figure 7 , Figure 8 , image 3 As shown, the fully automatic multi-functional multi-standard integrated bag making of the preferred embodiment of the present invention mainly includes: a non-stop splicing film unwinding device 1, a half-cut and half-folding forming frame device 2, a self-supporting device 3, and a front body Device 4, middle fuselage device 5 and rear fuselage device 6, the above devices are connected in sequence. Wherein, the self-supporting device 3 has applied for a patent, see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com