Printed full-sheet ink quantity automatic detection system based on machine vision and printed full-sheet ink quantity detection method

An automatic detection and machine vision technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve problems such as poor ink detection effect on printed sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

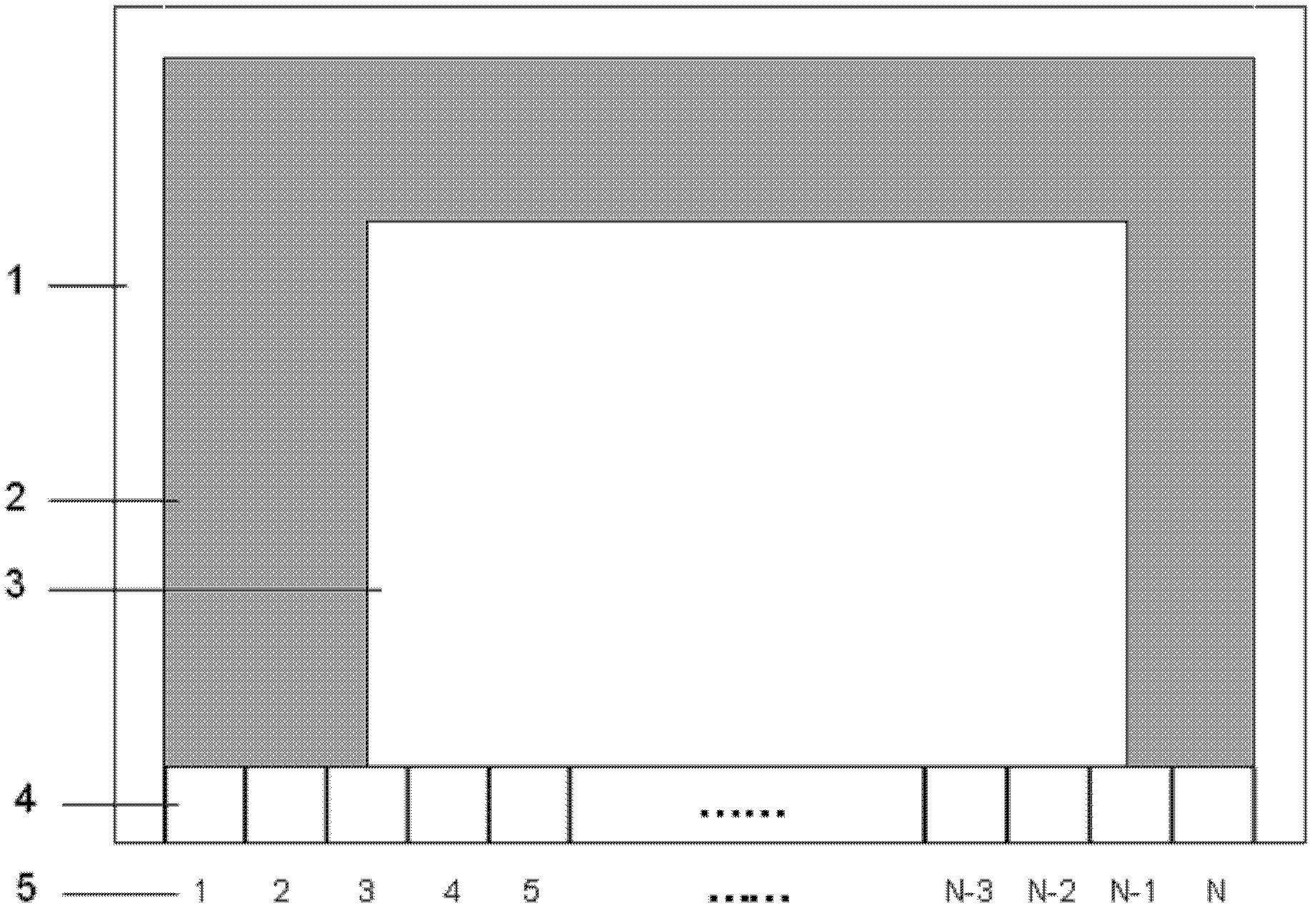

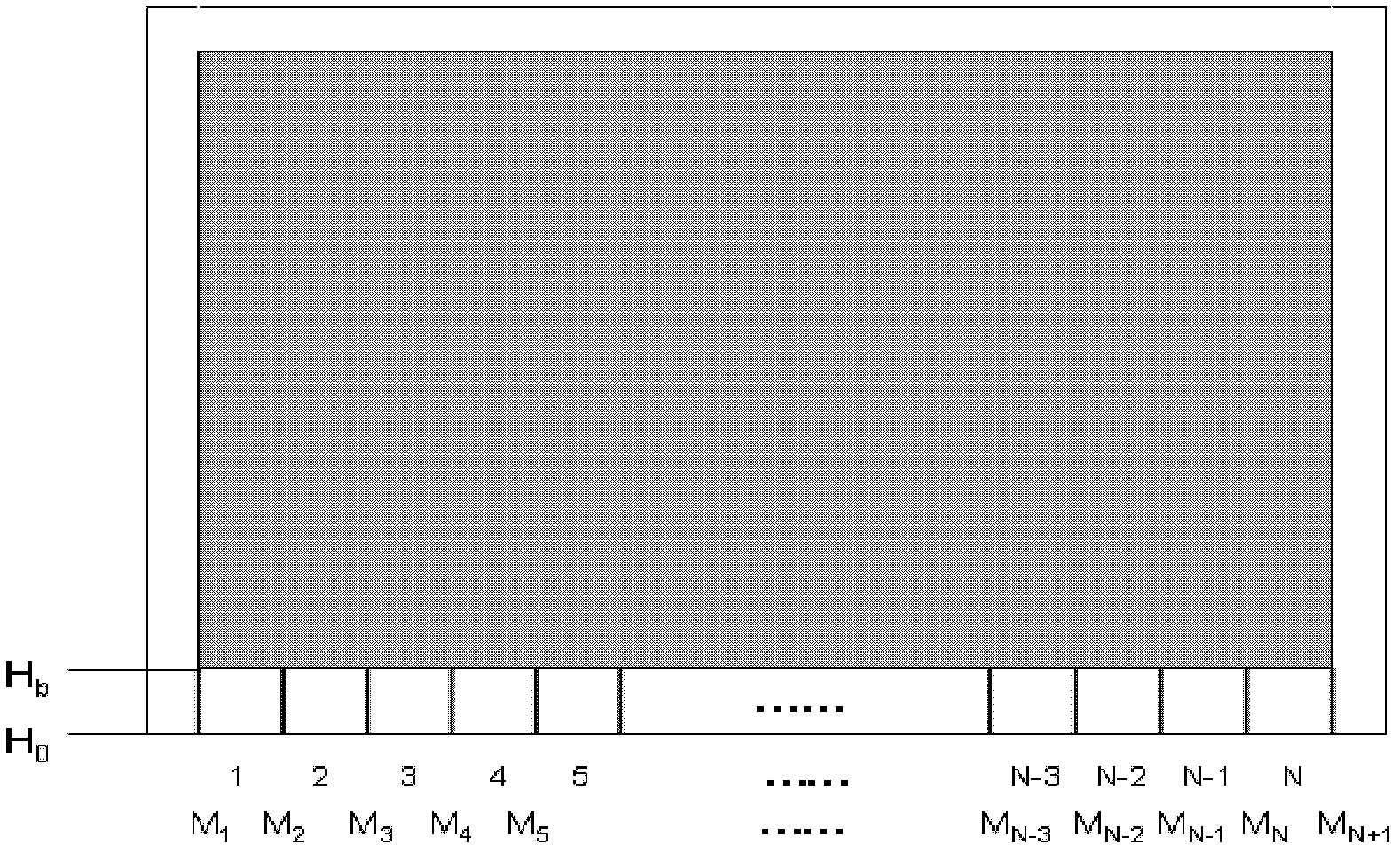

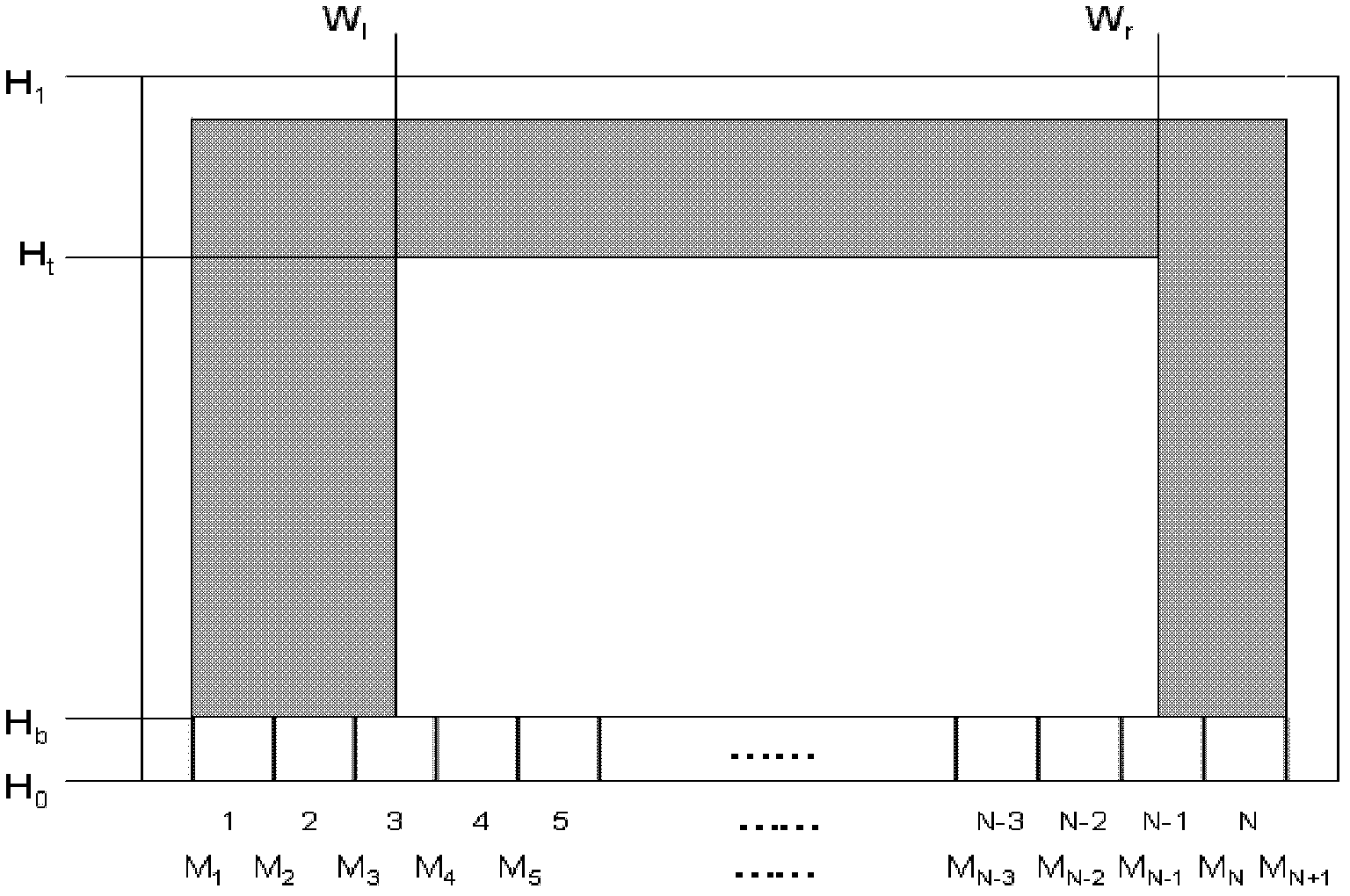

[0068] The structure of the machine vision-based automatic ink quantity detection system for the entire printed sheet of the present invention includes a color CCD camera, a rectangular LED light source and a detection platform. Detection platform such as figure 1 As shown, placed horizontally, the border 1 and the ink area marking area 4 are higher than the platform 2, the border 1 is white, the platform 2 is neutral gray, the length and width of the platform 2 are consistent with the length and width of the maximum printing opening of the printing machine, The background color of the ink area identification area 4 is white, and there are black straight lines perpendicular to the platform 2 on it. The distance between them is consistent with the width of the ink area of the printing machine. The number of ink areas in the ink area label 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com