A short-circuit and overload screening method at the end of traction power supply arm of high-speed railway

A technology of traction power supply and power supply arm, which is applied in the direction of circuit devices, emergency protection circuit devices, electrical components, etc., can solve problems such as indistinguishability, achieve the effect of reducing the number of trips and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

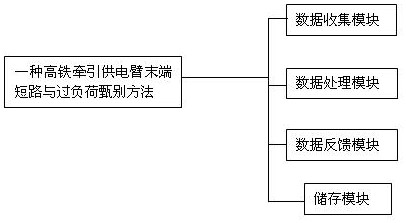

[0015] figure 1 As shown in , a method for identifying short circuit and overload at the end of a high-speed railway traction power supply arm is based on the application of relay protection equipment and feeder protection equipment in existing electrified railway traction substations, including a data collection module, a data processing module, and a data feedback module. After collecting relevant data through the data collection module, the AT substations on both sides of the traction substation and the storage module use a dedicated network channel to connect with the adjacent traction substations via optical fiber data lines. In the application, the real-time data of the feeder protection equipment of the traction substation and all AT stations and sub-zones in the power supply arm is collected through the data collection module. The data processing module analyzes the number and load of trains on the power supply arm, and feedback The module sends the processed data to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com