Method for packaging gift packs

A packaging method and gift technology, applied in the field of packaging, can solve problems such as low efficiency, affecting the production process of the production line, increasing enterprise management and employment costs, and achieving the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

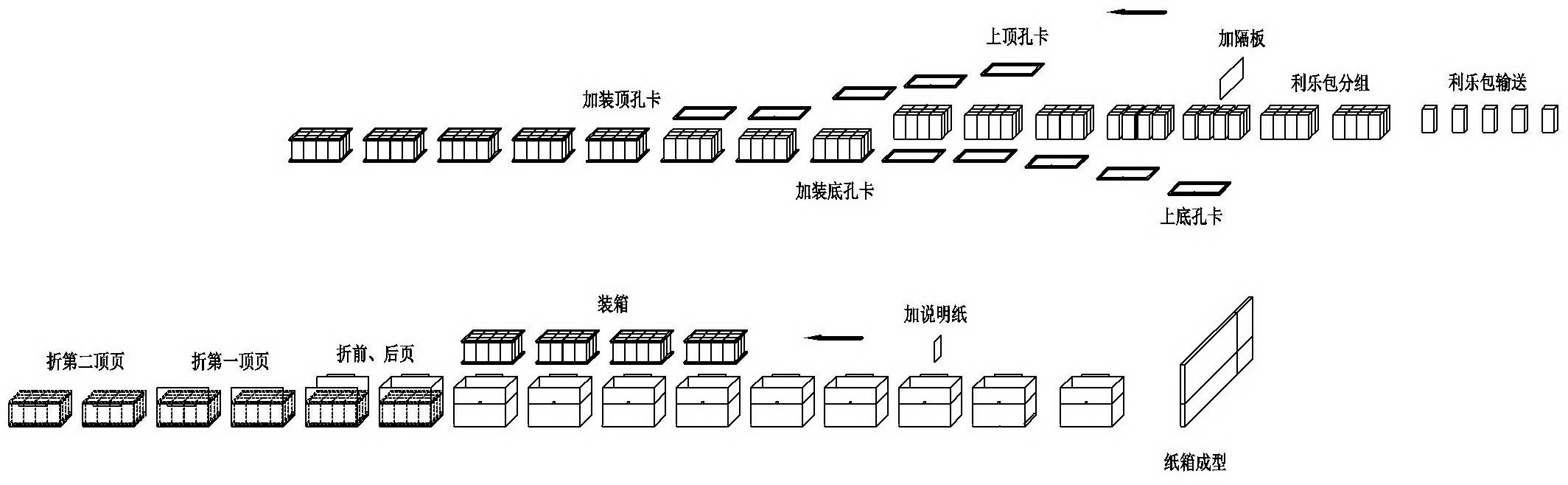

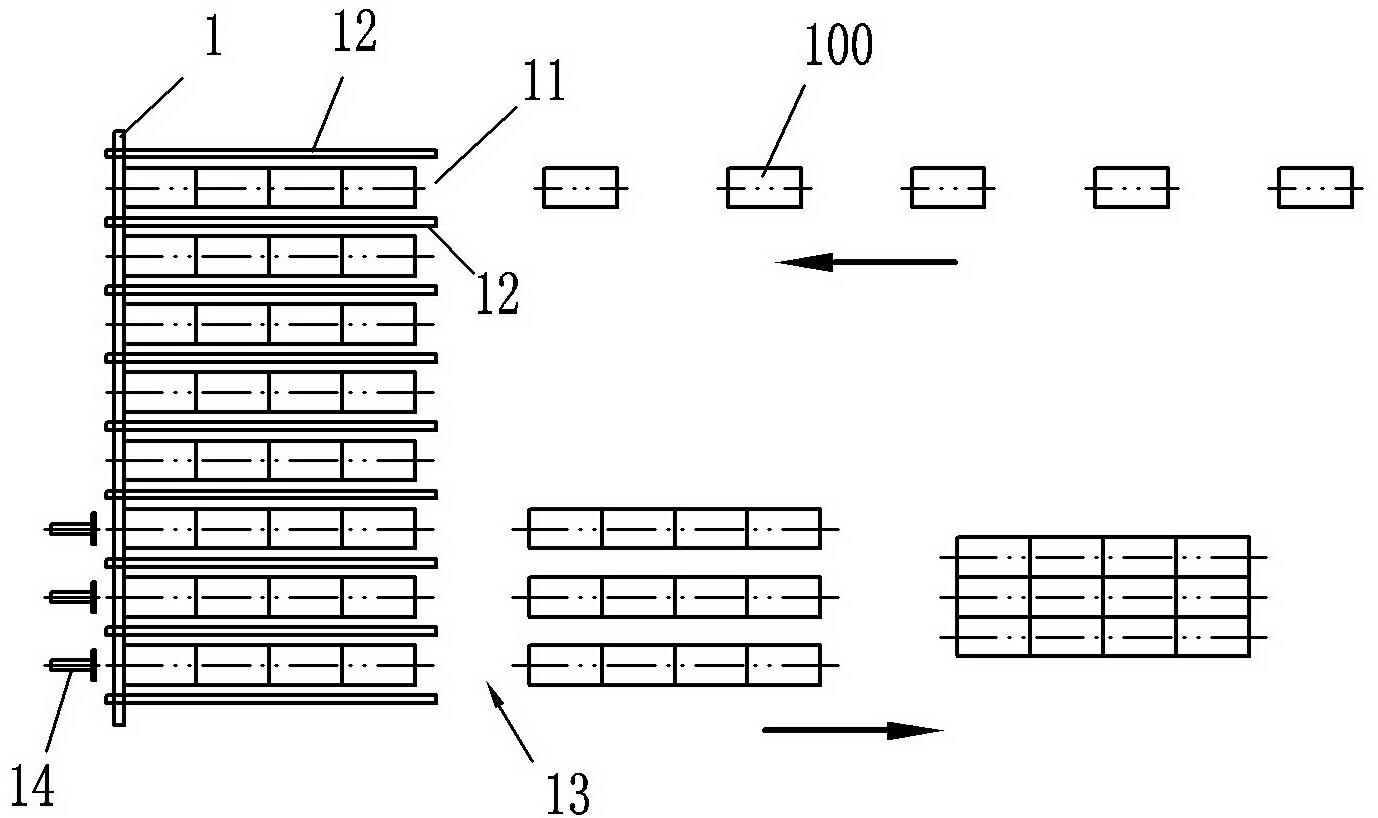

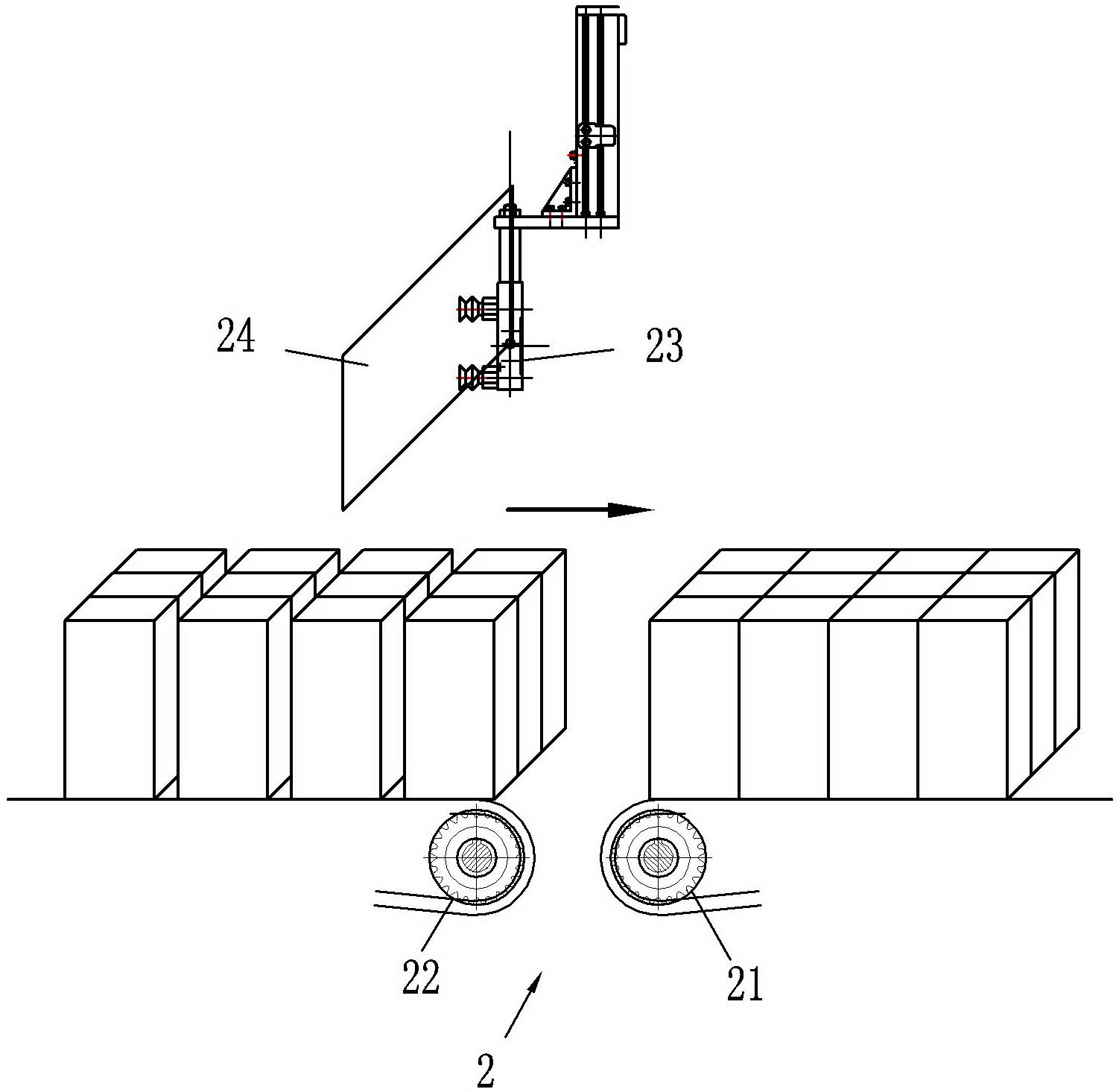

[0026] Such as figure 1 Shown is a flow chart of a packaging method for gift packaging according to the present invention, which includes the grouping process of carton packages, such as figure 2 As shown, the grouping process of the carton package includes the following steps:

[0027] A. The carton package 100 is transported to the corresponding slideway 11 in the grouping mechanism 1 through the front and rear two pack conveyor belts with speed difference, wherein the slideway 11 is separated by two adjacent guard plates 12, The conveying speed of the forward bag conveyor belt is greater than the backward bag conveyor belt, so that a certain gap can be maintained between the adjacent carton bags entering the forward bag conveyor belt from the backward bag conveyor belt and enter the slideway 11;

[0028] B. When the number of carton packages entering the chute 11 reaches a predetermined value, the transmission device drives the guard plate 12 to drive the carton packages ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com