Maintaining method of converter lining

A converter lining and lining technology, applied in the manufacture of converters, etc., can solve the problems of lack of protection, short attachment time, easy to fall off, etc., to improve the effect of secondary slag splashing, improve the service life of the converter, and improve gunning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

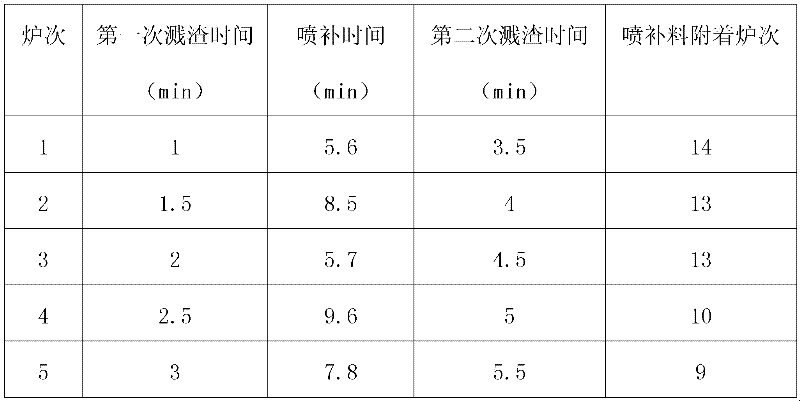

Embodiment 1

[0017] Take the 180-ton converter as an example. After the converter tapping is completed, the first slag splashing operation is directly carried out with high-pressure nitrogen, and the slag splashing time is controlled at 1min; and by adjusting the oxygen lance position, the adjustment plan is: adjust from low lance position to high lance position, every 5 seconds The gun position is increased by 150mm, and the slag with high MgO content is evenly sprayed on the surface of the furnace lining, so that the gunning material that is subsequently gunned can be easily combined with it. The purpose of adjusting the position of the oxygen lance and controlling the slag splashing time is to prevent the newly formed slag splashing layer from being too thick, causing the gunning material to fall off with the slag splashing layer.

[0018] After the first slag splashing is over, the furnace lining is quickly gunned, and the gunning material is sprayed on the surface of the furnace lining t...

Embodiment 2

[0021] Take the 180-ton converter as an example. After the converter tapping is completed, the first slag splashing operation is directly carried out with high-pressure nitrogen, and the slag splashing time is controlled at 2.5 minutes; and by adjusting the nitrogen gun position, the adjustment plan is: adjust from low gun position to high gun position, every 5 seconds The gun position is increased by 80mm, and the slag with high MgO content is evenly sprayed on the surface of the furnace lining.

[0022] After the first slag splashing, the furnace lining is quickly sprayed, and the spray gun is used to spray the gunning material on the weak part of the furnace lining surface, and the spraying time is controlled at 9.6min.

[0023] Immediately after the gunning is completed, the second slag splashing operation is carried out, and the time is controlled at 5 minutes, so that a new slag splashing layer is formed on the outside of the gunning material. In the second splashing operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com