Three-station knitting cam system

A triangular system and three-station technology, applied in the field of triangular systems, can solve problems such as difficult manufacturing, installation, use and maintenance, and complex structures, and achieve the effects of low processing and manufacturing costs, simple and compact structure, and easy manufacturing, installation, and use and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

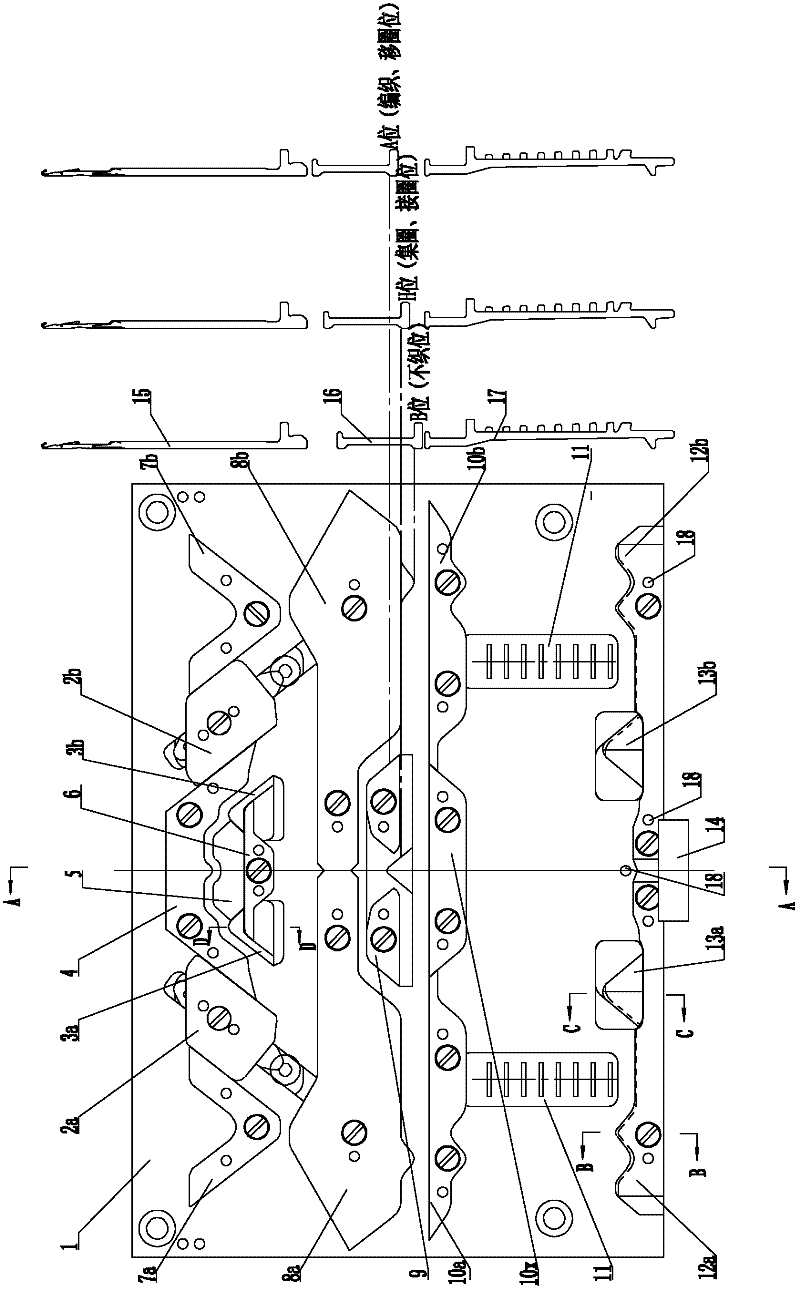

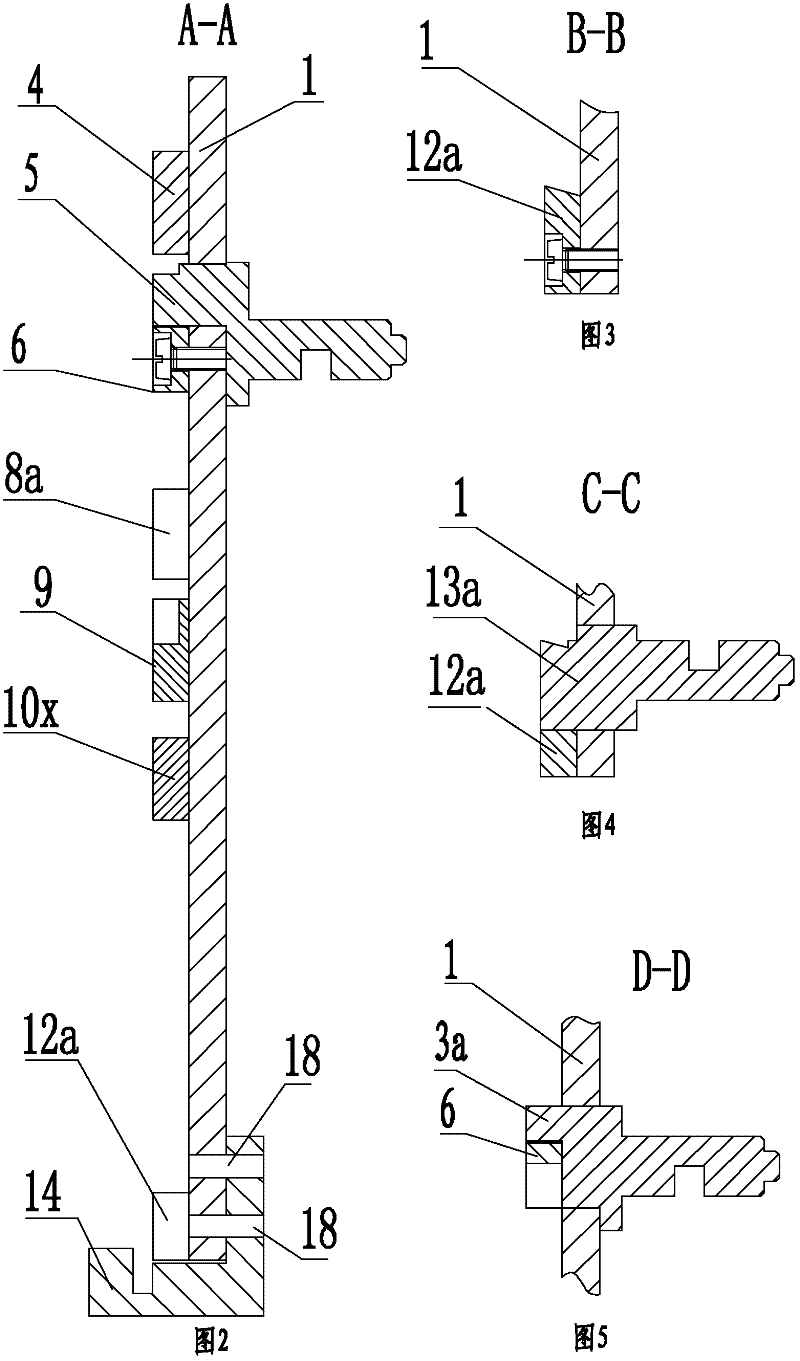

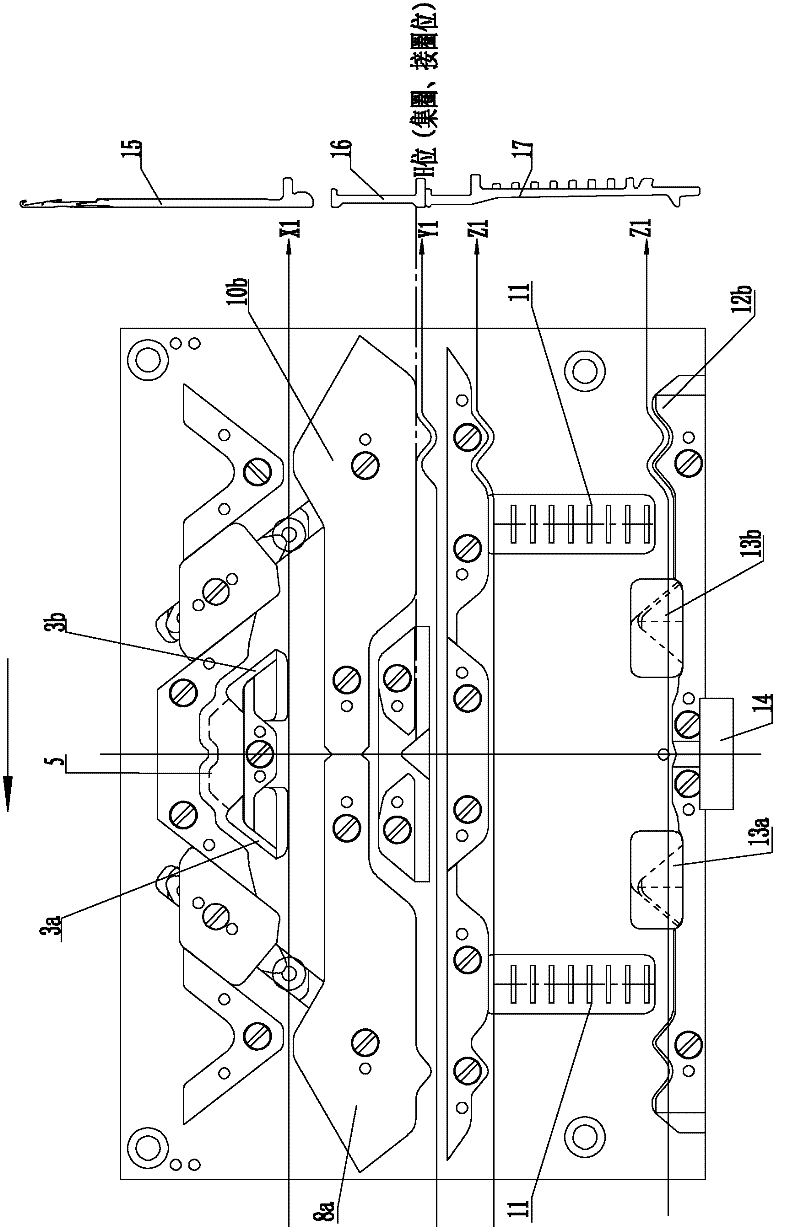

[0029] Such as figure 1 and figure 2 As shown, the present invention includes: a rectangular triangular base plate 1; a herringbone triangle 4, which is symmetrically fixed on the upper side of the front plate of the triangular base plate 1; the density triangle pair formed by the left density triangle 2a and the right density triangle 2b, The left and right density triangles 2a, 2b are symmetrically located on the left and right sides of the herringbone triangle 4 and are all connected with the front surface of the triangular bottom plate 1 by sliding fit. The sliding fit connection structure is not described here because it is a known technology; the needle guard triangle pair composed of the left needle guard triangle 3a and the right needle guard triangle 3b, the left and right needle guard trian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com