Non-woven fabric and process for producing same

A manufacturing process and non-woven technology, applied in the field of non-woven fabrics and their manufacturing processes, can solve problems such as large differences in tear resistance and large MD:CD ratios, so as to reduce cloud spots or fiber bundles. The difference in tear resistance, the effect of increasing the number of fiber arrangements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

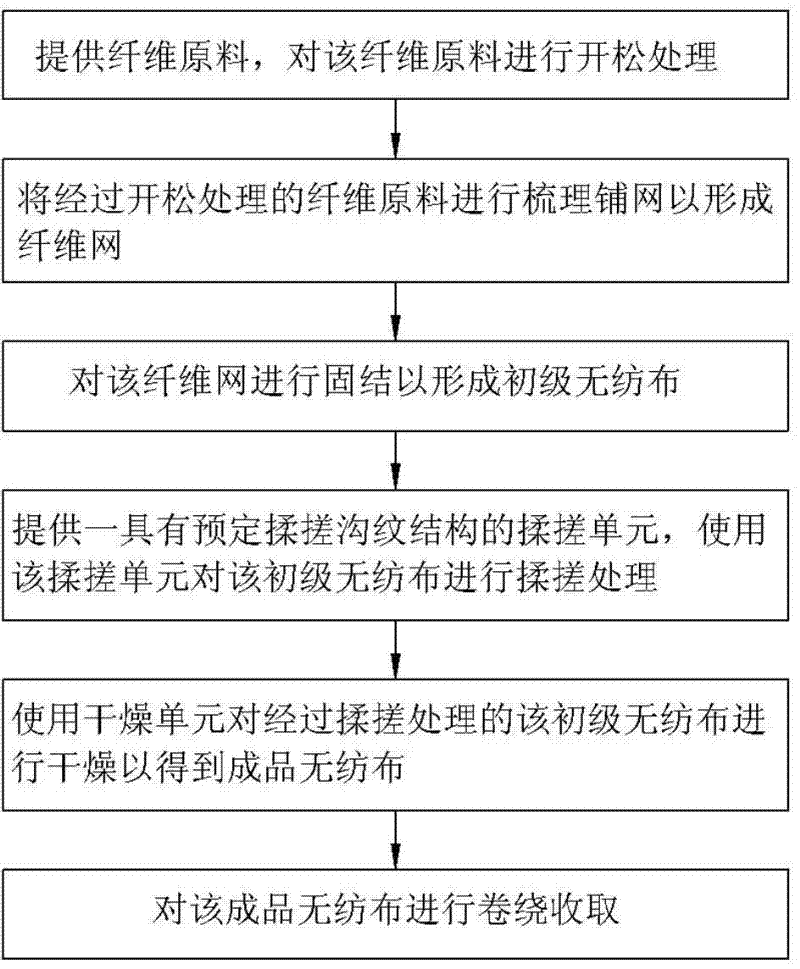

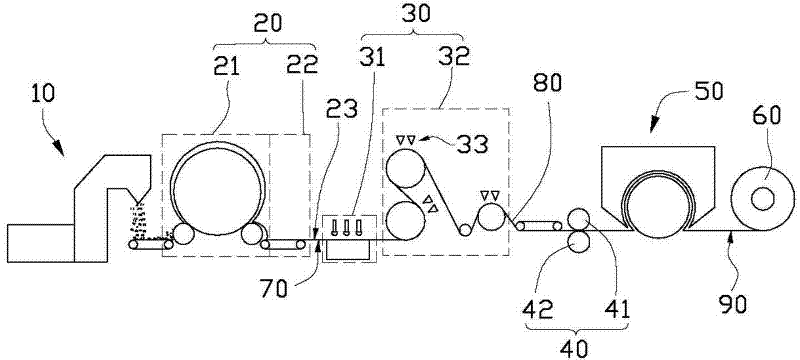

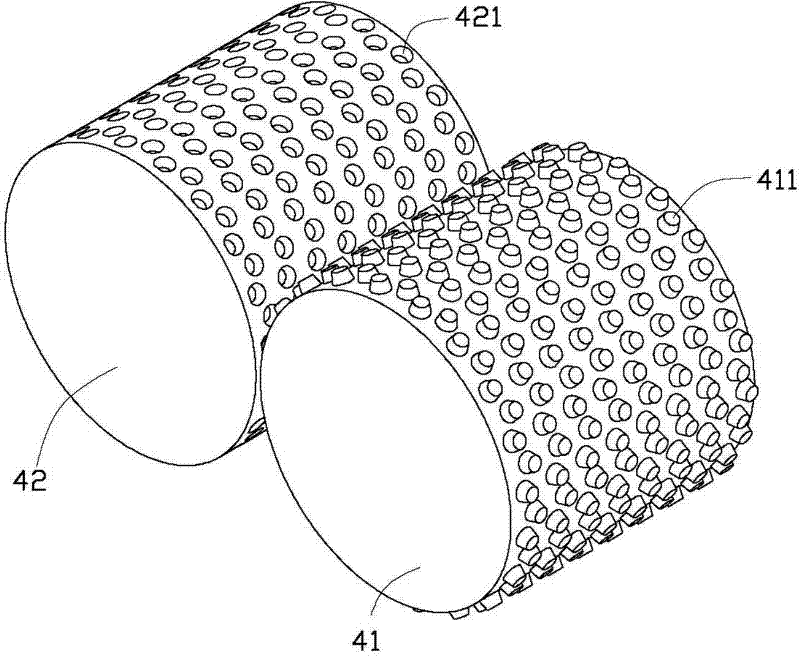

[0020] Please also see Figure 1 to Figure 6 As shown, the non-woven fabric manufacturing process flow provided by the embodiment of the present invention includes the following steps.

[0021] (1) Provide fiber raw materials, and open the fiber raw materials.

[0022] In the general non-woven fabric manufacturing process, before the fiber raw material is carded and laid, it is necessary to use an opener to open the fiber raw material.

[0023] In this embodiment, the fiber opening unit 10 is used to open the fiber raw material. Its working principle is to tear and loosen non-woven materials such as fiber and cotton through the relative movement between machines, so that large entangled fibers can be loosened into small pieces or bundles. In particular, when one or several different fiber raw materials need to be mixed according to different proportions according to the design requirements of the product, sending the mixed fiber raw materials to the opener for full opening c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com