Rubbing roller, embossing process applying rubbing roller and embossed wet tissue prepared by embossing process

A technology of embossing and wet wipes, which is applied in the direction of fabric kneading/softening, textile and papermaking, fabric surface trimming, etc. It can solve the problems of large differences in tear resistance, high vertical and horizontal strength, and MD/CD of non-woven products. Ratio is large, to achieve the effect of reducing the longitudinal and transverse strength ratio, increasing the bulk thickness, and reducing the difference in tear resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

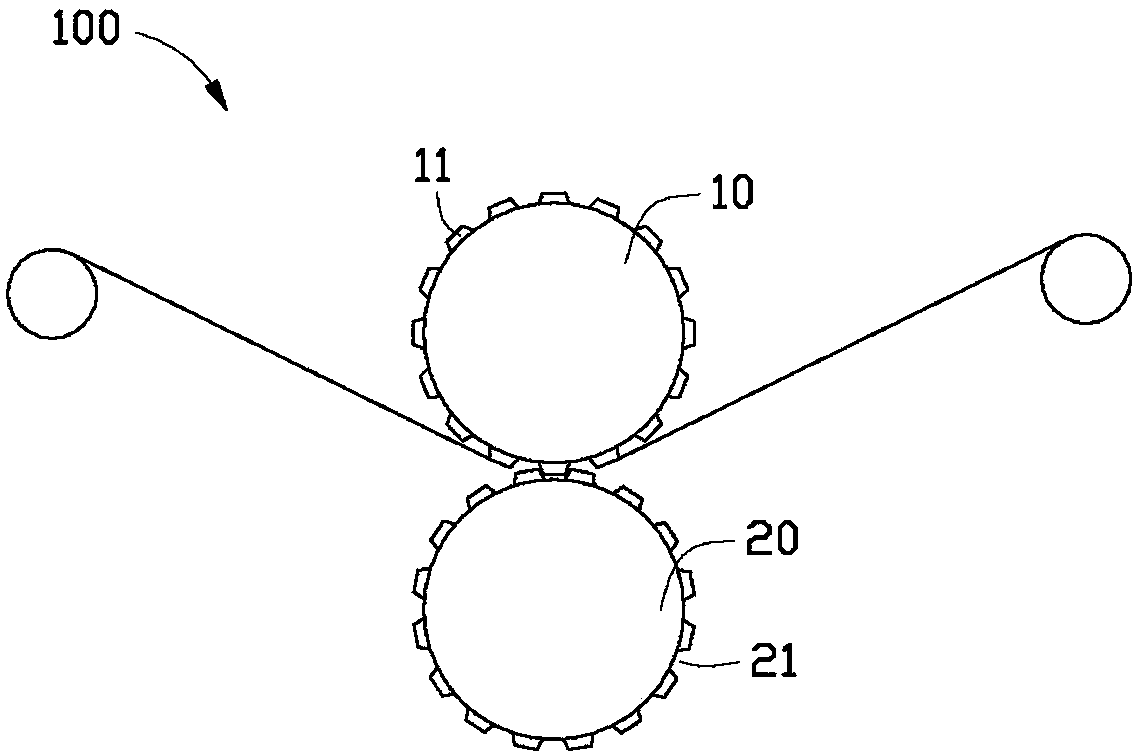

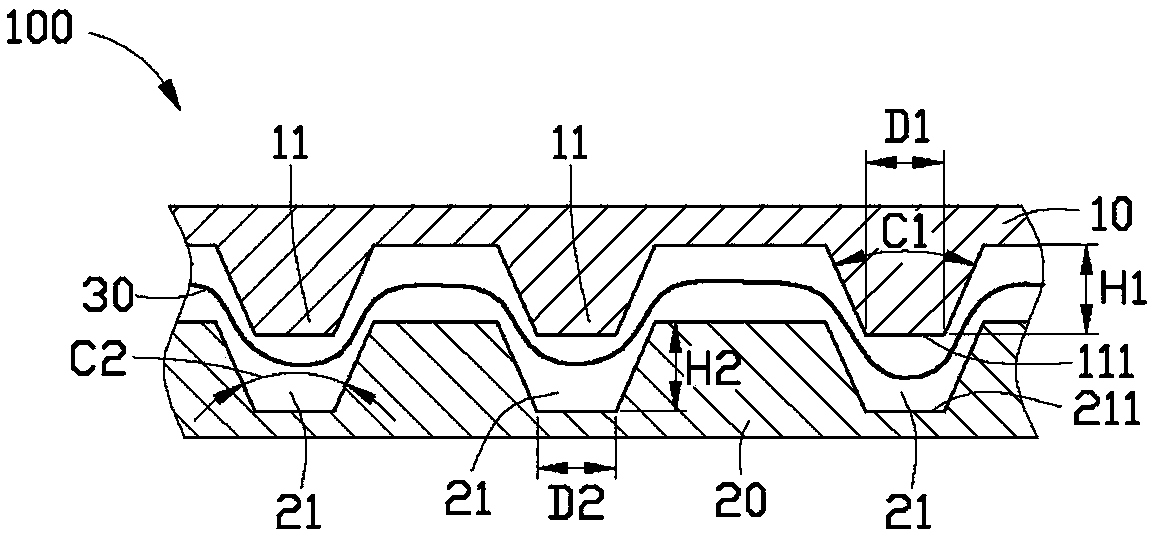

[0021] Please also refer to figure 1 and figure 2 , The kneading roll 100 of the present invention includes an upper kneading roll 10 and a lower kneading roll 20 matched to each other. Both the upper rubbing roller 10 and the lower rubbing roller 20 are cylindrical. The upper kneading roller 10 has a plurality of protrusions 11 extending outwards, and the lower kneading roller 20 has a plurality of grooves 21 recessed inwardly, and the protrusions 11 of the upper kneading roller 10 and the lower kneading roller 20 Groove 21 is one-to-one matching setting, when upper rubbing roller 10 and lower rubbing roller 20 rotate mutually, the protrusion 11 of upper rubbing roller 10 stretches in the groove 21 of lower rubbing roller 20 . Both the upper rubbing roller 10 and the lower rubbing roller 20 are steel rollers, or one of the upper rubbing roller 10 and the lower rubbing roller 20 is a wool roller, and the other is a steel roller.

[0022] The multiple protrusions 11 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com