Non-woven fabric manufacturing equipment

A technology for manufacturing equipment and non-woven fabrics, which is applied in the direction of textiles and papermaking, non-woven fabrics, fabric kneading/softening treatment, etc. It can solve the problems of large differences in tear resistance and large MD:CD ratio, etc., and achieve cloud reduction. "spot" or fiber bundle phenomenon, increase bulk, and increase the number of fiber arrangements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

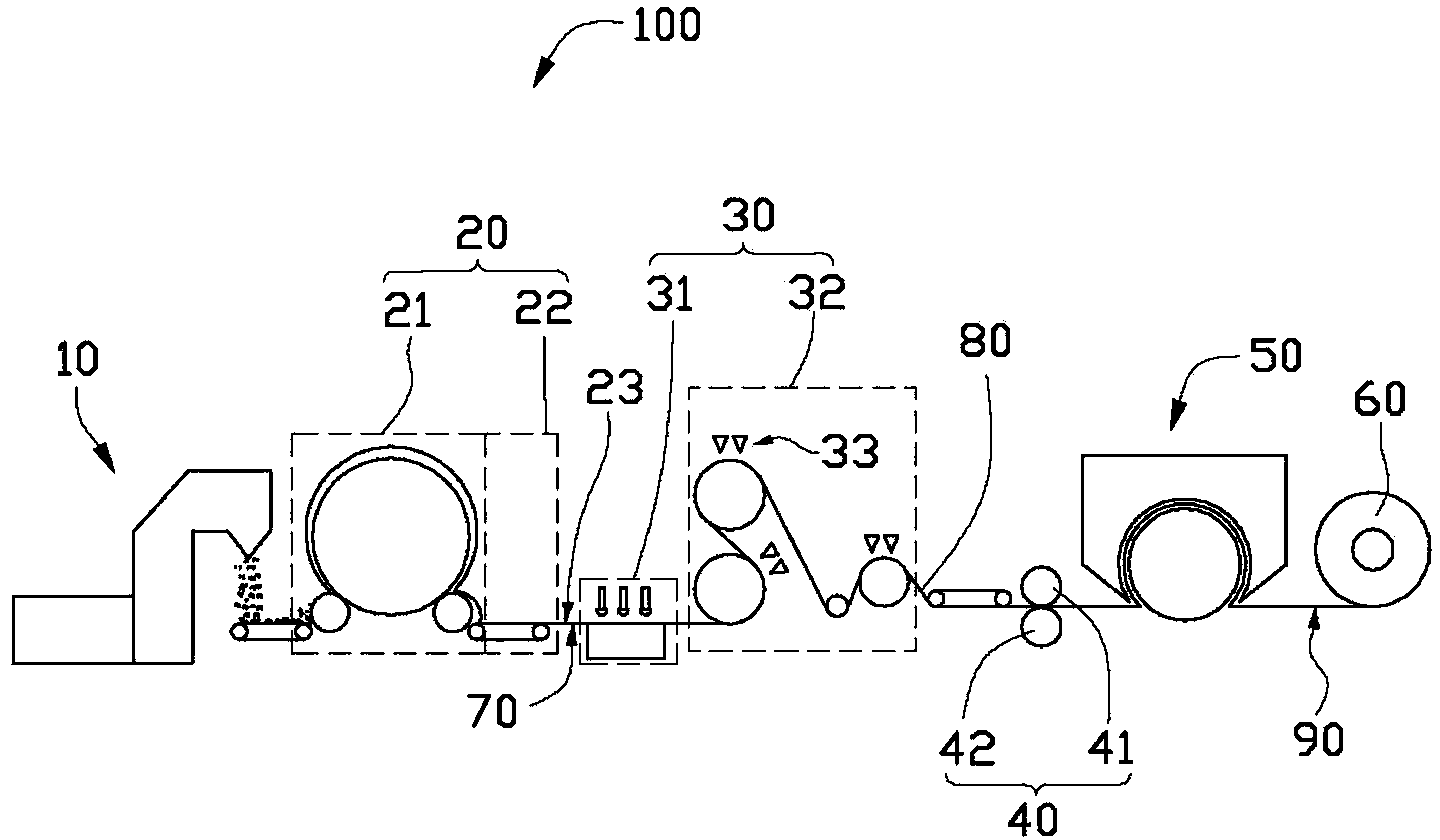

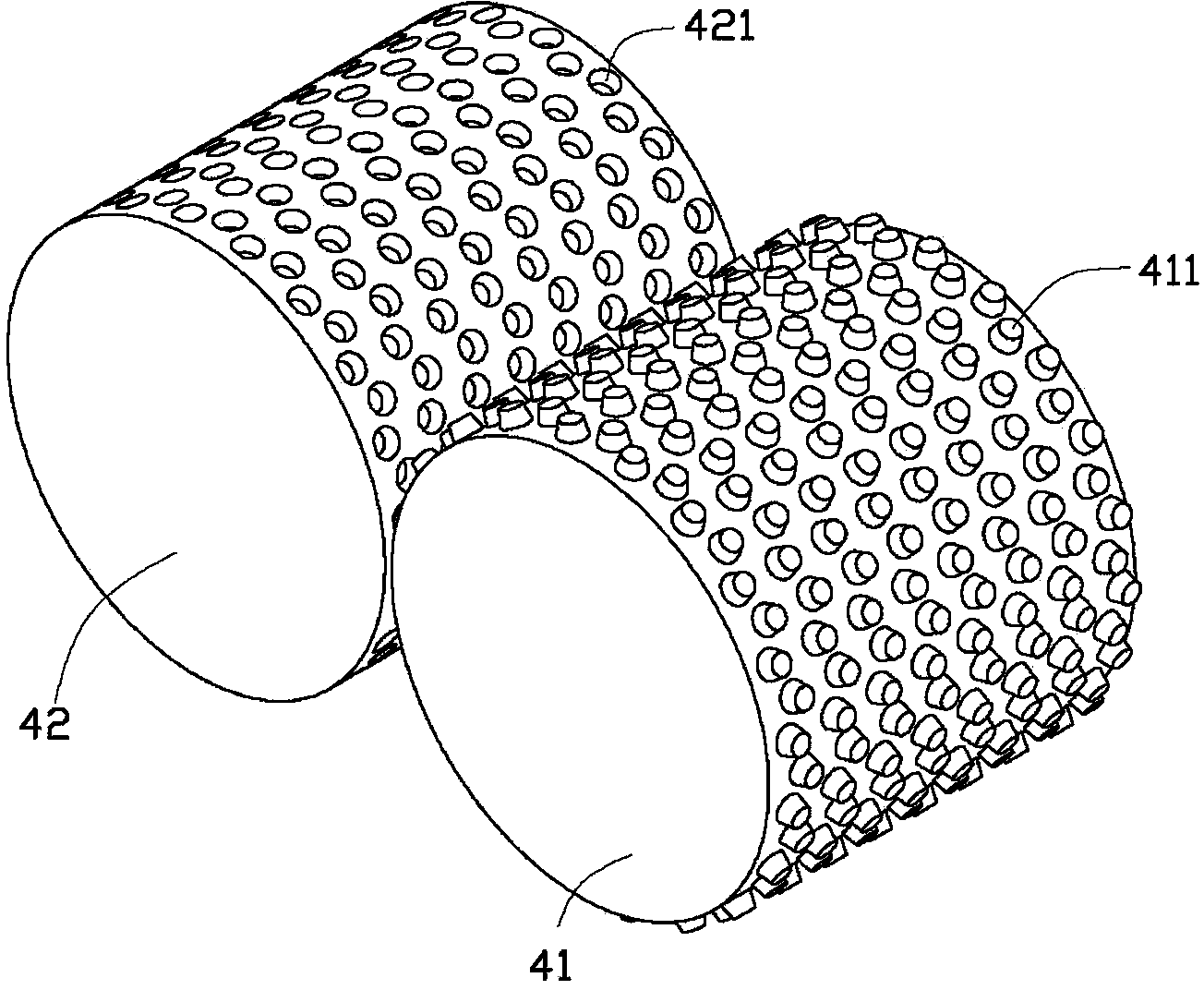

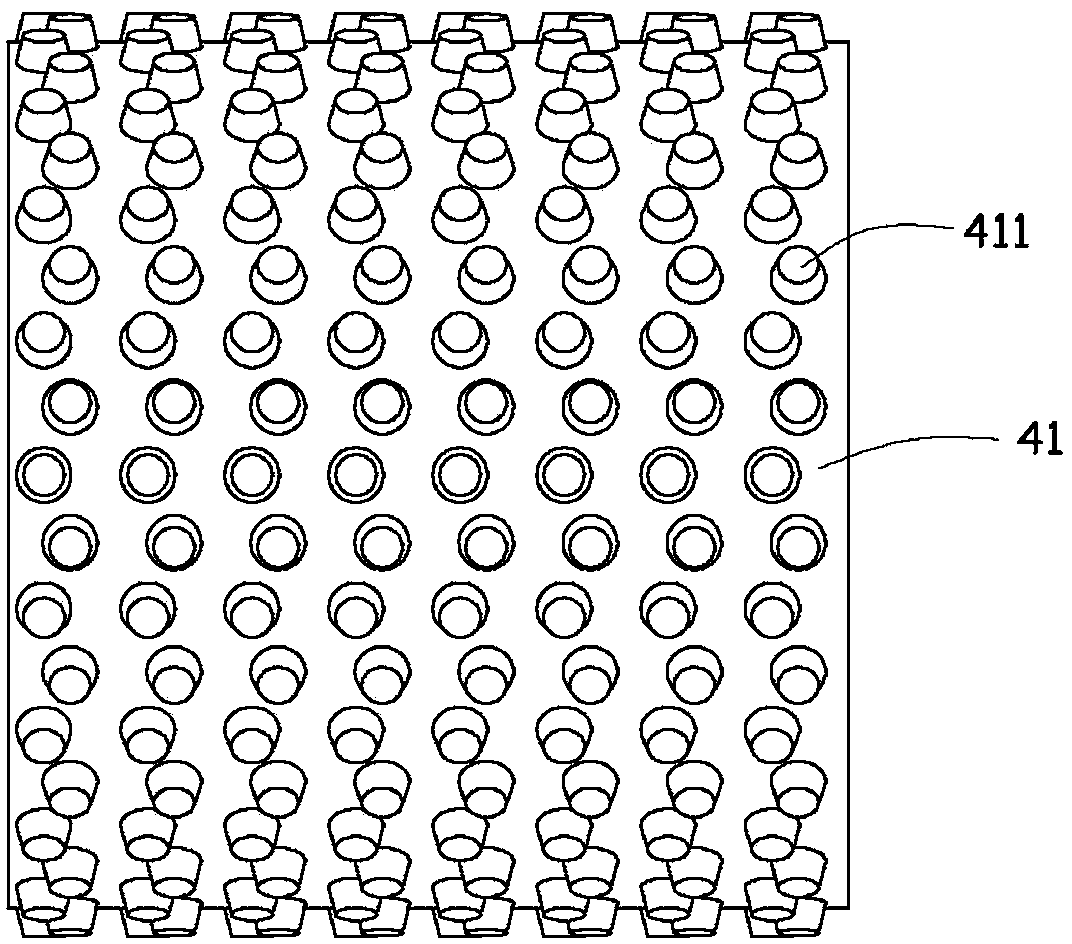

[0018] Please also see Figure 1 to Figure 5 , The non-woven fabric manufacturing equipment 100 provided by the embodiment of the present invention includes a fiber opening unit 10 , a carding and laying unit 20 , a consolidation unit 30 , a kneading unit 40 , a drying unit 50 and a winding unit 60 .

[0019] The fiber opening unit 10 mainly uses the relative movement between machines to tear and loosen non-woven materials such as fibers and cotton, so as to loosen large entangled fibers into small pieces or bundles. In this embodiment, according to different product requirements, one or several different fiber raw materials may be mixed in different proportions and sent to the fiber opening unit 10 for full opening.

[0020] It should be noted that the fiber opening unit 10 used in the present invention can be any fiber opening mechanism that can be applied in the non-woven fabric production process.

[0021] It can be understood that, according to different non-woven fabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com