Method for designing asymmetric timing for continuous variable valve timing (CVVT)

A valve timing and design method technology, applied in mechanical equipment, valve details, engine components, etc., can solve problems such as timing that cannot be changed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

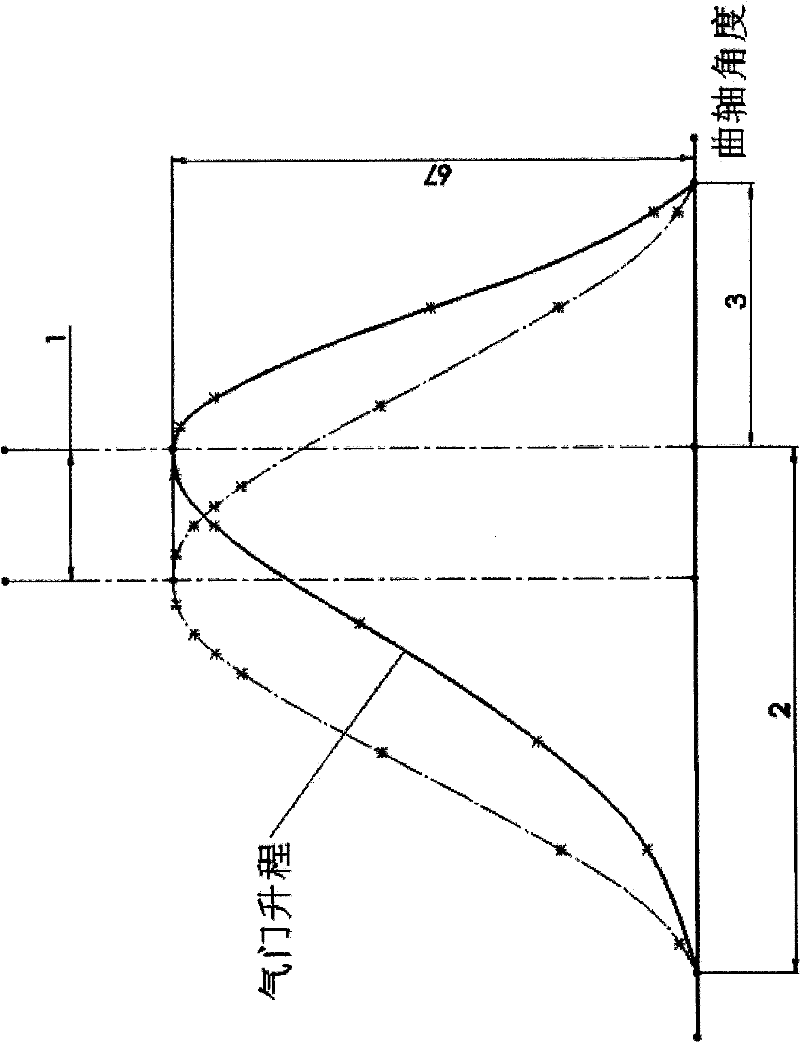

[0012] An exemplary embodiment of the present invention is described in detail below. In this exemplary embodiment, the so-called crankshaft angle refers to half of the numerical value of the crankshaft angle of the internal combustion engine, which is convenient to combine with the cam angle of the previous figure to illustrate the intention of the invention.

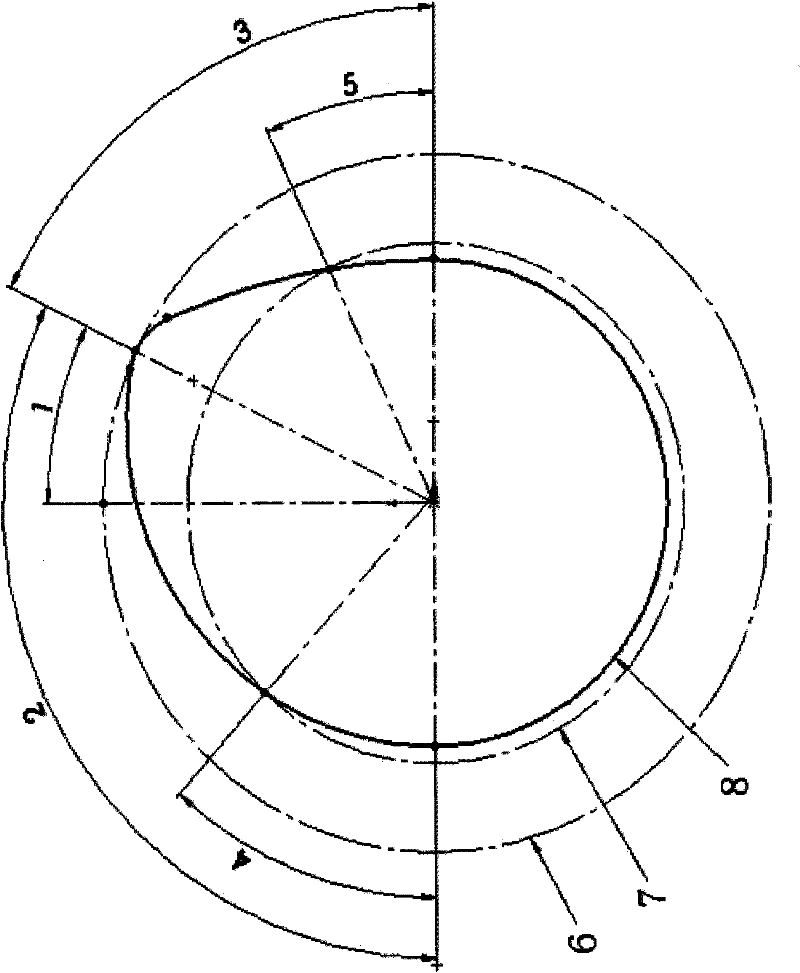

[0013] figure 1 It is a schematic diagram of the cam, and it can be seen that the protruding part of the cam is not symmetrical. Assuming that the cam rotates counterclockwise, angle 1 is the angle at which the fixed point with the largest radius of the cam deviates from the center position, angle 2 is the angle of the curve that makes the valve open, angle 3 is the angle of the curve that makes the valve close, and the sum of angle 2 and angle 3 is the angle of the crankshaft corresponding to the cam. The so-called central position is the angular position when angle 2 and angle 3 are equal. Radius 6 is the radius o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com