Two-stage through-flow turbine with ultralow specific speed

A technology of tubular water turbine and specific speed, applied in the direction of reaction engine, hydroelectric power generation, mechanical equipment, etc., can solve the problems of affecting the ventilation effect of cooling towers, unable to meet the requirements of shaft power, affecting the cooling effect of cooling towers, etc. Application prospect and promotion value, effect of radial size reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The double-click tubular ultra-low specific speed turbine designed for a circulating water cooling tower with a capacity of 3,000 tons per hour, a water head of 13 meters, and a speed of 136 rpm has an efficiency of over 85%, which fully meets the requirements of the directly connected cooling fan. required power requirements.

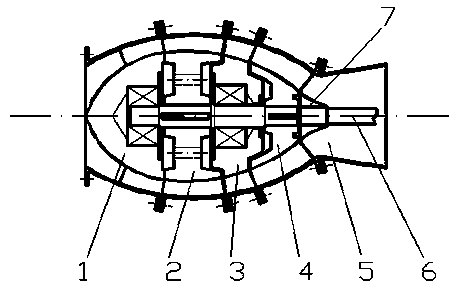

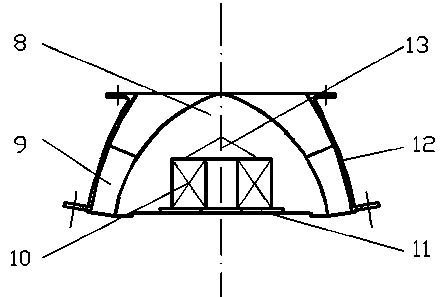

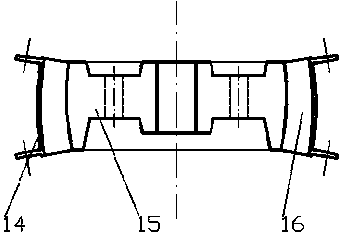

[0060] The appearance of the water turbine is like a spindle, figure 2 The shell (12) of the first guide vane chamber is made of standard carbon steel with a thickness of 10mm and rolled into a circular table-shaped tube with an inner diameter of 580mm in the upper opening and 895.78mm in the lower opening, with a height of 409mm. There are 12 flanges with Φ20mm bolts and light holes. Connect the upper port flange with the water diversion pipe flange through 12 Φ20mm bolts, and connect the lower port flange with the water pipe flange through 12 Φ20mm bolts. image 3 The upper port of the first runner housing (14) is flanged. image 3 The shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com