Roller bearing and cage for roller bearing

A technology for rolling bearings and cages, applied in the field of angular contact ball bearings and cages for angular contact ball bearings, which can solve the problems of rolling elements that cannot be fixed by cages, difficulties in the assembly process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

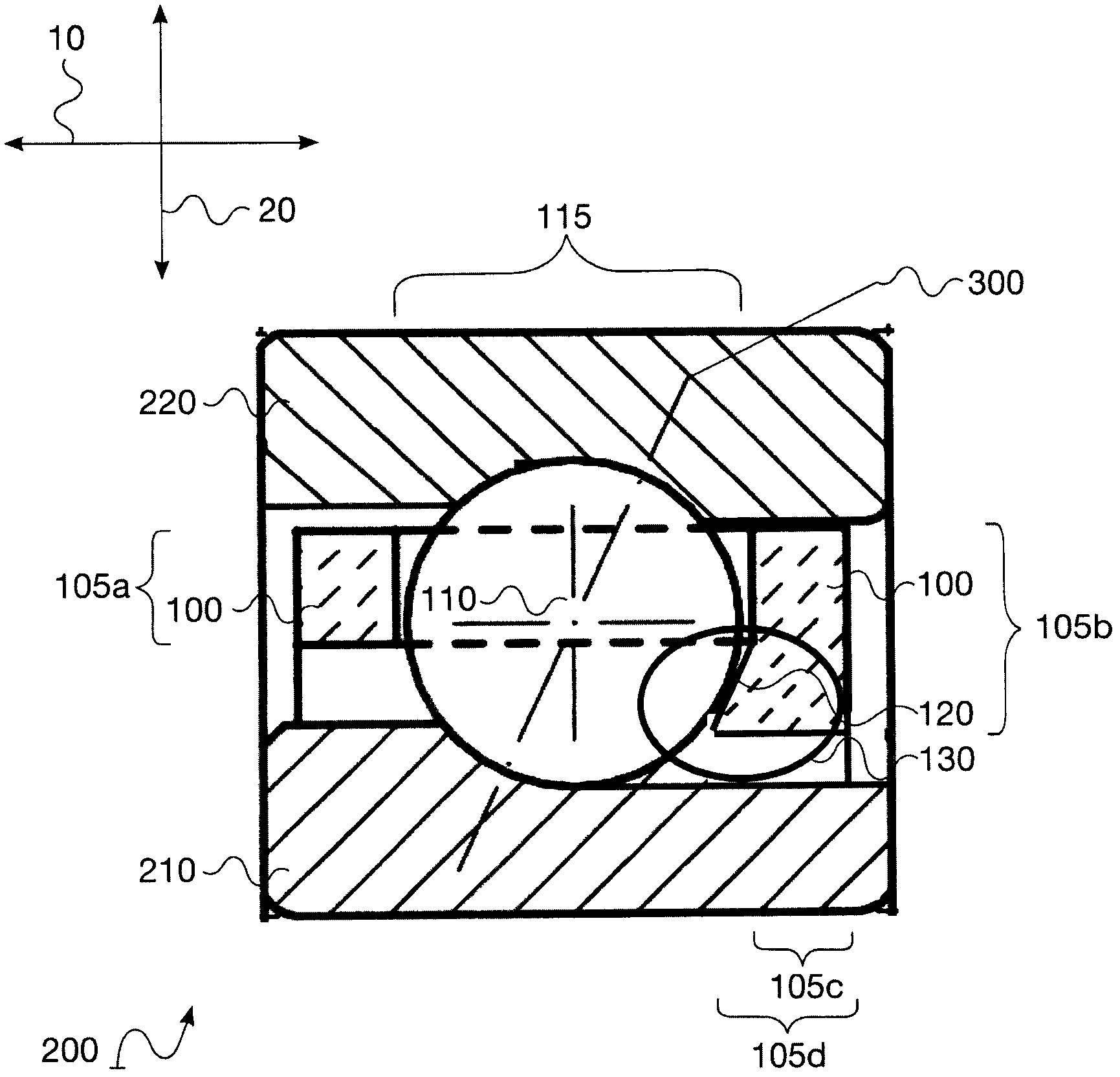

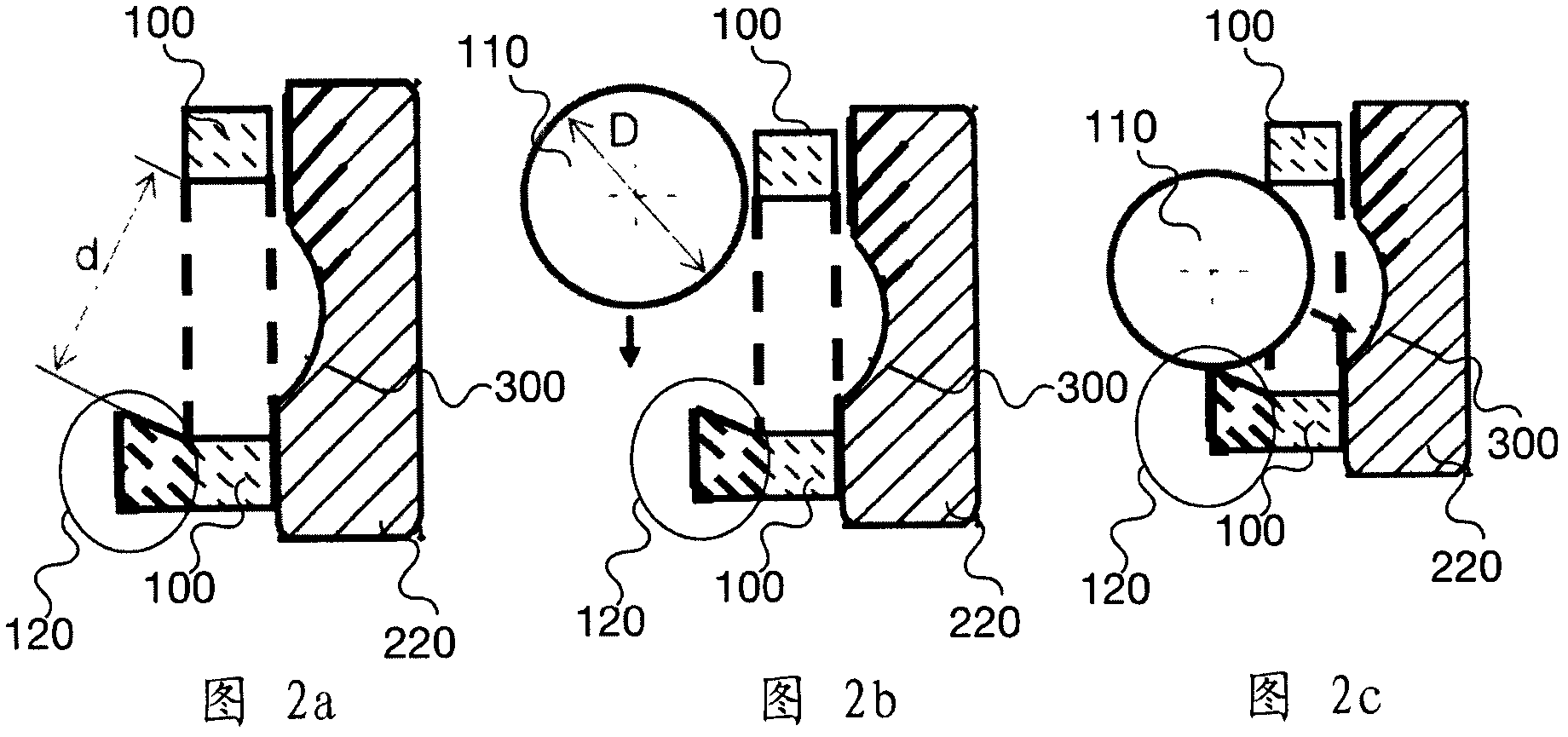

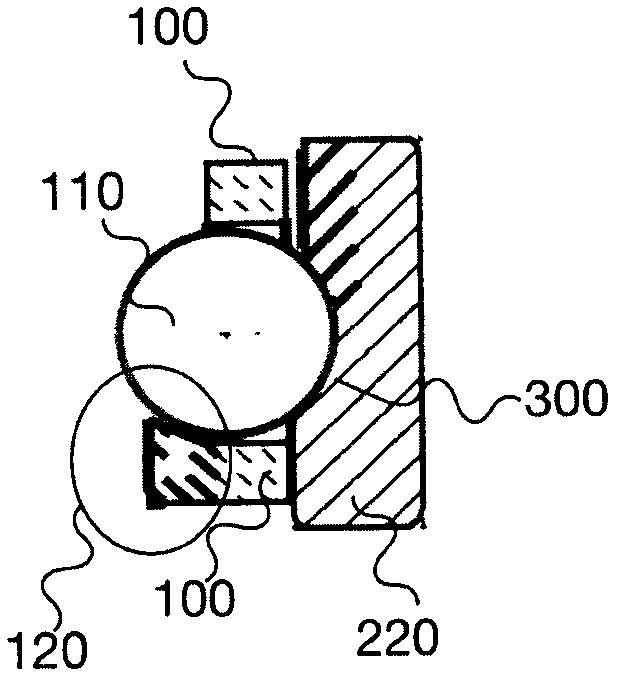

[0018] figure 1 An exemplary embodiment of a rolling bearing 200 is shown. The rolling bearing 200 includes an inner ring 210 and an outer ring 220 . Rolling bearings 200 in figure 1 is designed, for example, as an angular contact ball bearing, as indicated by the tilt axis 300 . Between the inner ring 210 and the outer ring 220 is an embodiment of the rolling elements 110 and the cage 100 . The cage 100 is annular and is designed to accommodate the rolling bodies 110 of the rolling bearing 200 . figure 1 In this respect, a cross section through pocket 115 of cage 100 is shown, arrow 10 indicating the axial direction and arrow 20 specifying the radial direction. also, figure 1 The small rib 120 is shown adjacent to the bearing inner ring 210 . In general, it is also conceivable in other exemplary embodiments that the small rib 120 is adjacent to the bearing outer ring 220 . Examples are not limited to figure 1 on the geometric shape.

[0019] In an embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com