Ceiling lamp module

A technology for ceiling lamps and lamp tubes, applied in parts of gas discharge lamps, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve problems such as intolerance to frequent switching, difficult maintenance, poor versatility, etc., to achieve Simple high-altitude operation, convenient installation and disassembly, and the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

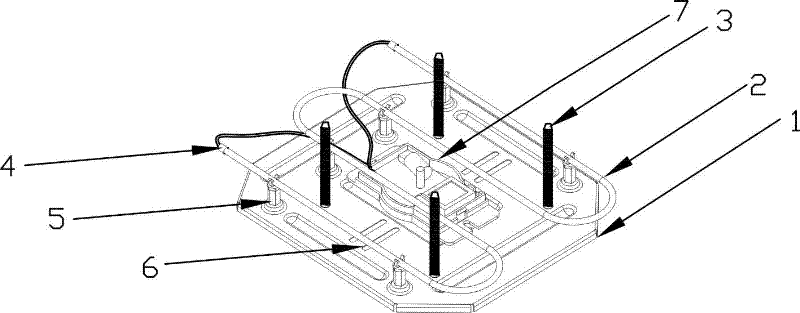

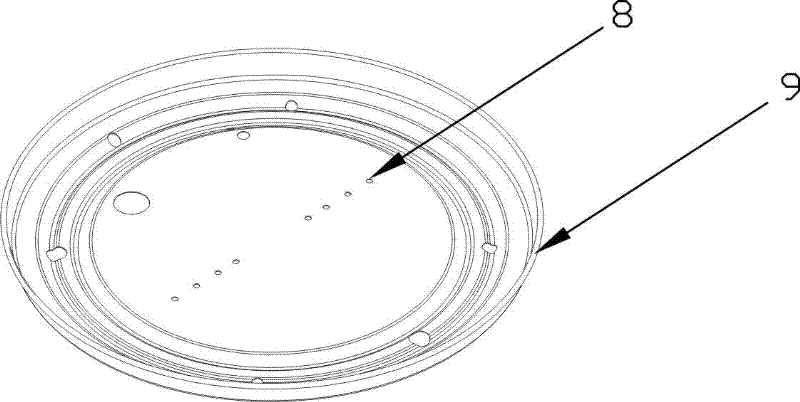

[0021] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes a tray 1, a lamp tube 2 is fixed on the tray 1 through a clip 5, an inverter 7 is half-embedded on the tray 1, two locking slots 6 are provided on both sides of the tray 1, and the locking The card slot 6 is matched with the positioning hole 8 of the lamp panel of the ceiling lamp, and the lamp tube 2 is electrically connected with the inverter 7 through the metal cap 4 at the tube end.

[0022] Clip 5 is a plastic card.

[0023] The four corners of the tray 1 are symmetrically provided with bolts 3 .

[0024] The lamp tube 2 is a cold cathode fluorescent lamp, and the electrode is a double guide wire electrode. The two pins of the electrode are welded and sealed with the glass cup to form a preset whole. Matching the size of the lamp, the preset whole is sealed and connected to both ends of the lamp tube, and an air guide tube is provided on one side of the lamp tube an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com