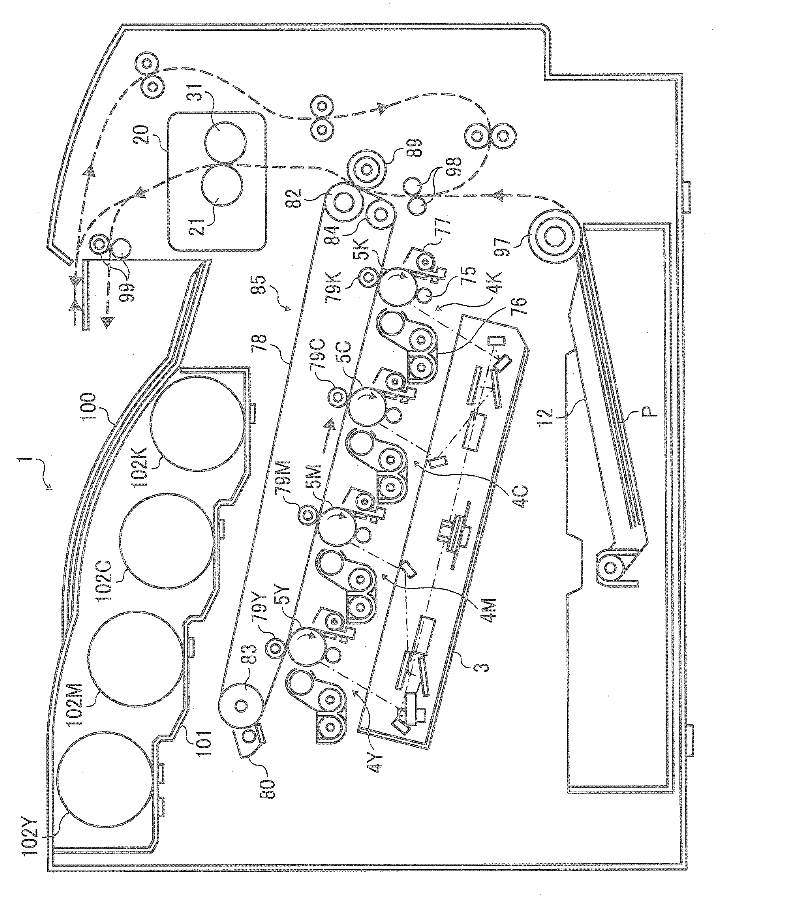

Fixing device, and image forming apparatus

A technology for fixing parts and components, which is applied in the direction of electric recording process applying charge pattern, equipment for electric recording process applying charge pattern, electric recording technique, etc., can solve problems such as difficulties and assembly problems, and achieve better assembly. , the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

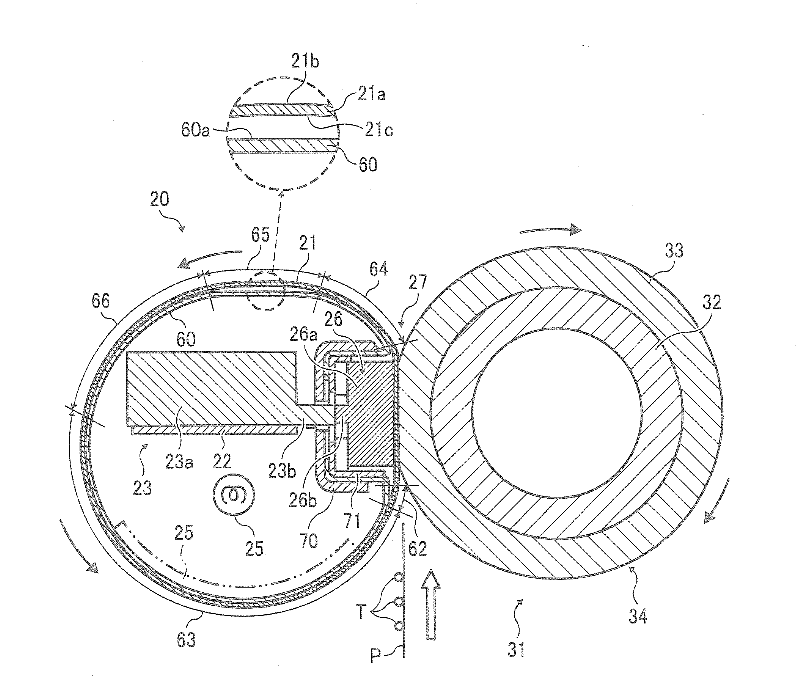

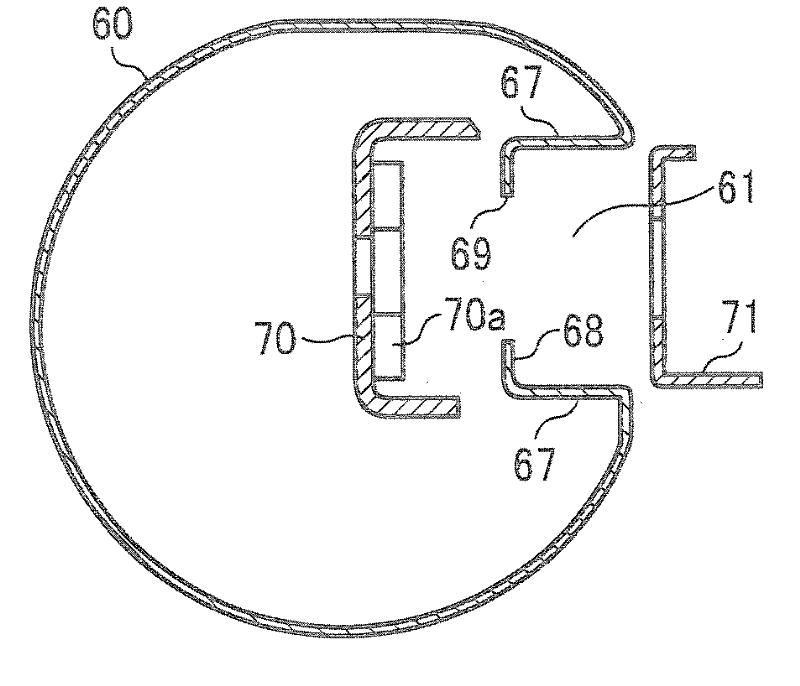

[0223] Under the same conditions as the above embodiment, using Figure 5 For the support member 60 of the size and shape shown, only the difference ( L2L1 ) between the outer peripheral length L1 of the supporting member 60 incorporating the nipping forming member 26 and the inner peripheral length L1 of the fixing belt 21 was changed, and various measurements were performed. Measurements were performed on the relationship between the difference in peripheral length and the surface temperature of the supporting member 60 , and the difference in peripheral length and the frictional force between the supporting member 60 and the fixing belt 21 .

[0224] Figure 11 Indicates its result. Such as Figure 11As shown, when the circumference difference exceeds 0.9 mm, the surface temperature of the supporting member 60 exceeds the prescribed temperature limit value. That is, when the difference in circumference exceeds 0.9 mm, since the fixing belt 21 is loosely wound around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com