Terminal insertion device and terminal insertion method

A terminal insertion device and terminal technology, which is applied in the direction of coupling device, connecting device components, and contact assembly/disassembly, etc., can solve the problems of unable to insert the terminal smoothly, interfere with the upper and lower ends of the opening, etc., so as to prevent the reduction of productivity. , the effect of improving the insertion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

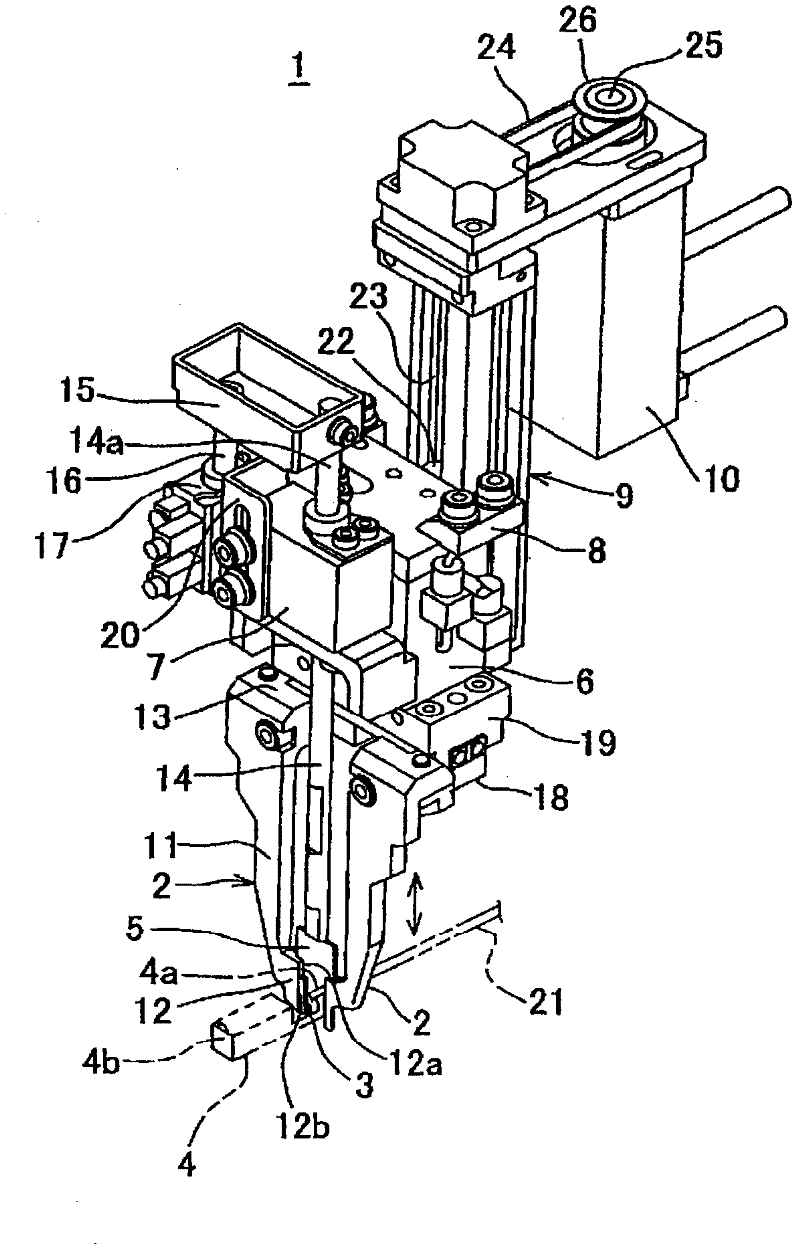

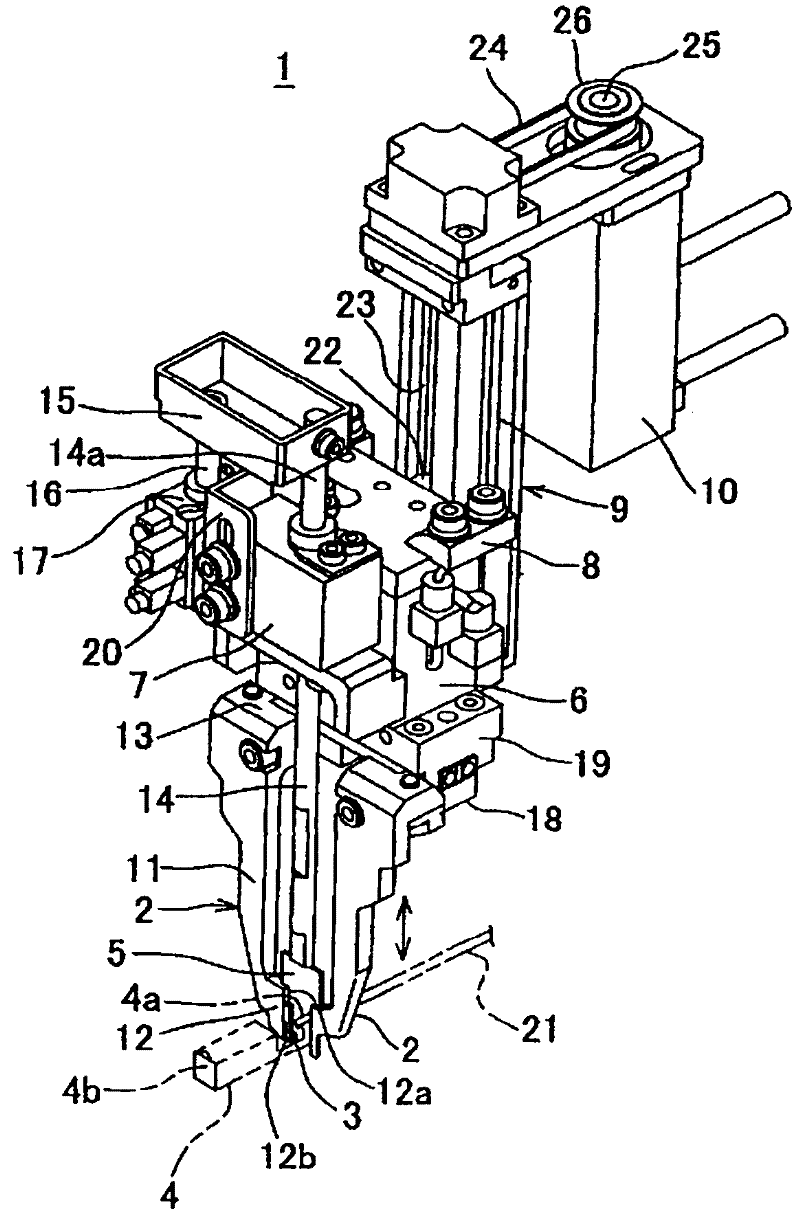

[0037] figure 1 It is a figure which shows one Embodiment of the terminal insertion apparatus and terminal insertion method of this invention.

[0038] The terminal insertion device 1 has: a pair of left and right terminal buckles 2; a terminal pressing member 5 that pushes the terminal 4 against the upper side of the horizontal protrusion 3 at the lower end of the terminal buckles 2; opens and closes the pair of terminal buckles 2 The pneumatic chuck cylinder 6; the cylinder 7 for lifting and lowering the terminal pressing member 5; the block part 8 for fixing the air chuck cylinder 6 and the cylinder 7; A rail-shaped vertical adjustment guide 9; and a servo motor (motor) 10 that drives the block portion 8 to move up and down along the vertical adjustment guide 9.

[0039] On at least one of the pair of terminal hooks 2 , preferably on both, a horizontal protruding portion 3 facing inward is provided. A pair of terminal buckles 2 are located on the left and right facing ea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap