Axial dual-stator brushless double-fed motor

A double-fed motor and double-stator technology, applied in electrical components, electromechanical devices, etc., can solve the problems of low utilization rate of public rotors, special squirrel-cage rotor structure, and large system occupied space, so as to reduce ineffective length, compact structure, The effect of high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

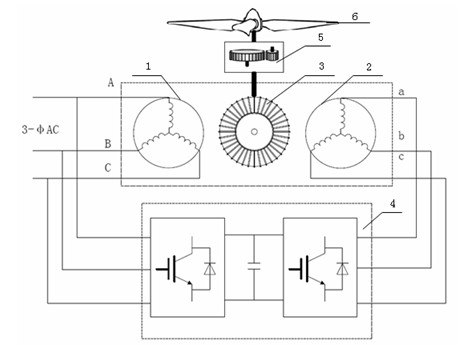

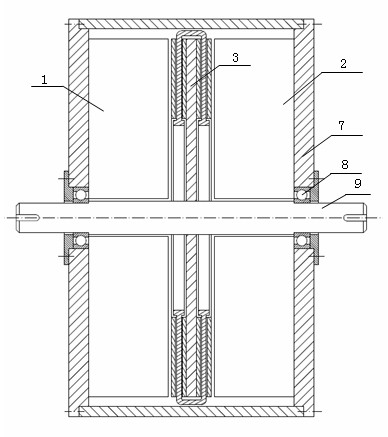

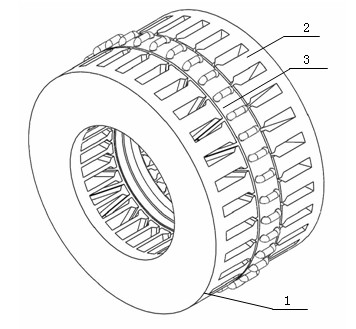

[0032] figure 1 For the dual-stator brushless doubly-fed wind power generation system, the motor includes a bidirectional rectification inverter 4, an end cover 7, a rotating shaft 9, a rotor 3 arranged on the rotating shaft 9, and left symmetrically arranged on both axial sides of the rotor 3. Stator 1 and Right Stator 2. The left stator 1 has a set of left stator windings 12 with 2p poles, and the right stator 2 has a set of right stator windings 22 with 2q poles, where p and q are positive integers respectively. The left stator winding 12 is the main power winding and is directly connected to the grid or the main power supply; the right stator winding 22 is the control winding and is connected to the grid or an external circuit through the bidirectional power converter 4 . The above-mentioned 2p stator winding 12 and the 2q stator winding are all multi-phase symmetrical stator windings. The rotor 3 is mechanically connected to the fan wheel 6 directly or through the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com