Contact nip roll

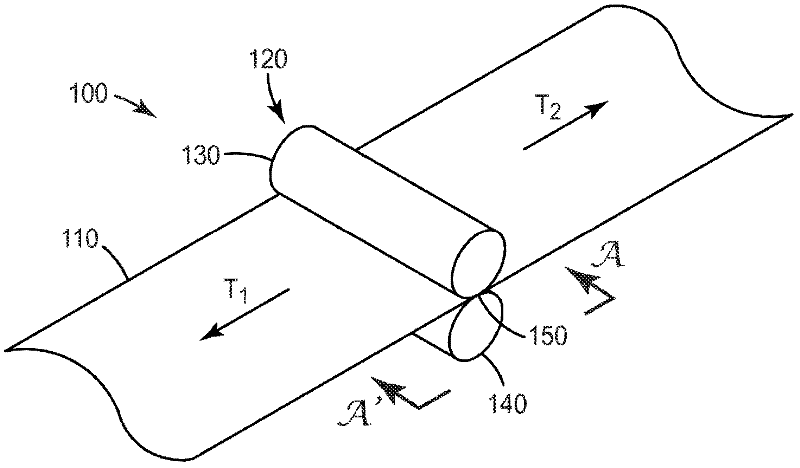

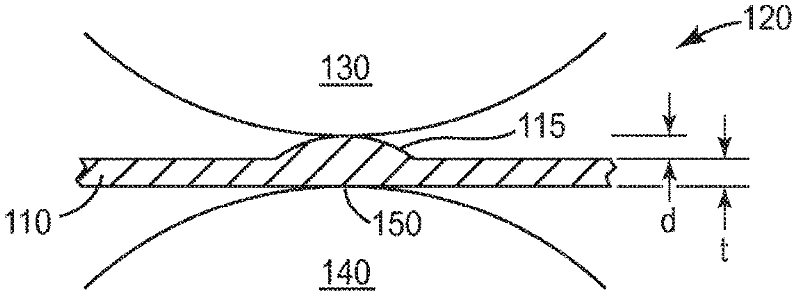

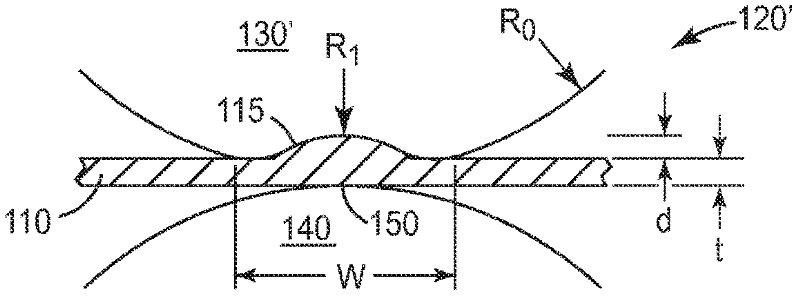

A technology of contact pressure and pressure roller, which is applied in the system field of rolling and clamping web materials, assembling improved contact pressure rollers, improved contact pressure rollers, and clamping web materials, which can solve the problems of web depression and web material Wrinkling, permanent web distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] Example 1-Manufacturing of improved contact nip roller

[0050] In each end of a 24" long aluminum tube with an outer diameter of 3.50 inches (8.89cm) and an inner diameter of 2.00 inches (5.08cm), a bearing with a diameter of 2.626 inches (6.670cm) and a depth of 0.4375 inches (1.111cm) is machined The inner hole of the bearing is used for the bearing that can receive a shaft with a diameter of 1.50 inches (3.81cm). The outer diameter of the tube is cut to be concentric with the inner diameter of the inner hole of the bearing. It will be 3.125 inches (7.937cm) in diameter Six equally spaced #10-32 threaded holes on the bolt circle are attached to each end of the tube.

[0051] The first compliant layer is coated on the tube. The first compliant material is a 0.75 inch (1.91 cm) thick elastomer coating of neoprene with a hardness tester hardness 30 provided by SI Industries, Inc., Blaine, MN, which is applied to the outside of the tube . Laser cut multiple rings with an ...

example 2

[0057] Example 2-Simulation of improved contact nip roller

[0058] The simulated improved contact nip roll shows that the cross web contact and pressure changes caused by the web thickness changes can be minimized. Several different nip pressures and web thicknesses were tested, indicating that the improved contact nip roll produces smaller contact area changes.

[0059] A 0.125 inch (0.3175 cm) thick sheet of urethane with a hardness tester hardness of 80 was wrapped around the partially finished nip roll of Example 1 to simulate a second compliant material coating. The simulated improved contact nip roller is set in a fixed bearing housing, and a 4-inch (10.16cm) diameter aluminum nip roller is actuated and pivoted by two 3.25 inch (8.255cm) inner diameter pneumatic cylinders. A nip force is applied between the two rollers. The pressure is released, and a cast polyethylene terephthalate (PET) sheet with a thickness of 0.030 inches (0.762 mm) to 0.062 inches (1.575 mm) is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com