Cigarette filter stick formed by mixing tows and paper disorderly and preparation and application method thereof

A cigarette filter rod and hybrid molding technology, which is applied in applications, e-liquid filter elements, tobacco, etc., to achieve the effects of avoiding accidental risks, simple operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

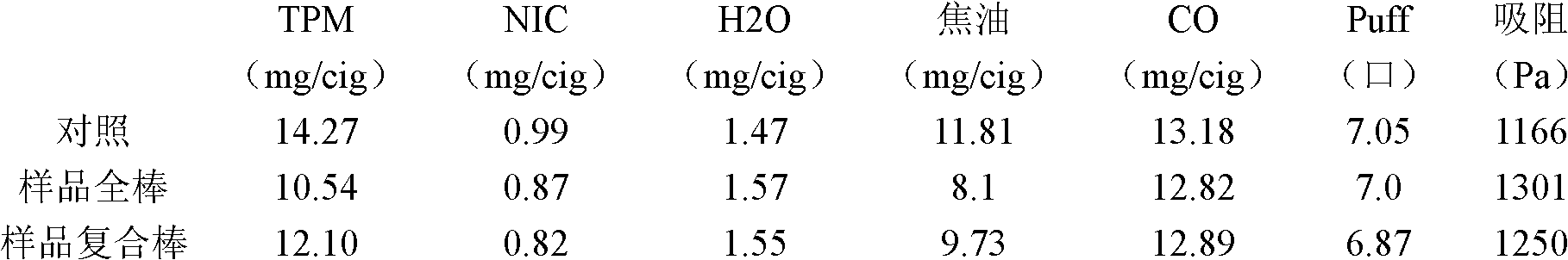

Embodiment 1

[0022] The 3.0 / 32000 acetate fiber tow is opened according to the ordinary acetate fiber filter rod production process, triacetin is applied, and sent to the bong through the output roller to prepare for molding; the paper for the cigarette paper tip and rod is simultaneously opened It is directly sent to the bong without triacetin; the tow and the paper enter the bong synchronously into the bong for one-time disorderly molding and slitting to make mouth rods. The prepared new filter stick is directly used in cigarettes, which can reduce tar by 3.71mg / cigarette compared with the control sample; it is used in cigarette production after being compounded with ordinary cellulose acetate rods at a ratio of 15:10, and can reduce tar by 2.08mg / cigarette compared to the control sample . The smoke detection data are shown in Table 1.

[0023] Table 1 Smoke detection data

[0024]

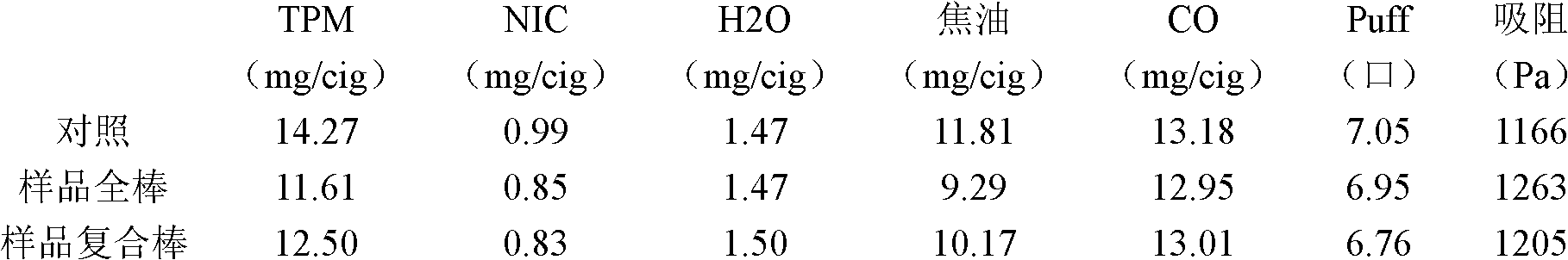

Embodiment 2

[0026] The 2.1 / 29000 acetate fiber tow is opened according to the ordinary acetate fiber filter rod production process, triacetin is applied, and sent to the bong through the output roller to prepare for molding; the paper for the cigarette paper tip and rod is simultaneously opened It is directly sent to the bong without triacetin; the tow and the paper enter the bong synchronously into the bong for one-time disorderly molding and slitting to make mouth rods. The prepared new filter rod is directly used in cigarettes, which can reduce tar by 2.52mg / cigarette compared with the control sample; it can be used in cigarette production after being compounded with ordinary cellulose acetate rods at a ratio of 15:10, and can reduce tar by 1.64mg / cigarette compared to the control sample . The smoke detection data are shown in Table 2.

[0027] Table 1 Smoke detection data

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com