Numerical control device and method for controlling numerical control device

A technology of numerical control device and control part, which is applied in the direction of digital control, positioning device, electrical program control, etc., can solve the problem of inability to shorten the tool change cycle and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

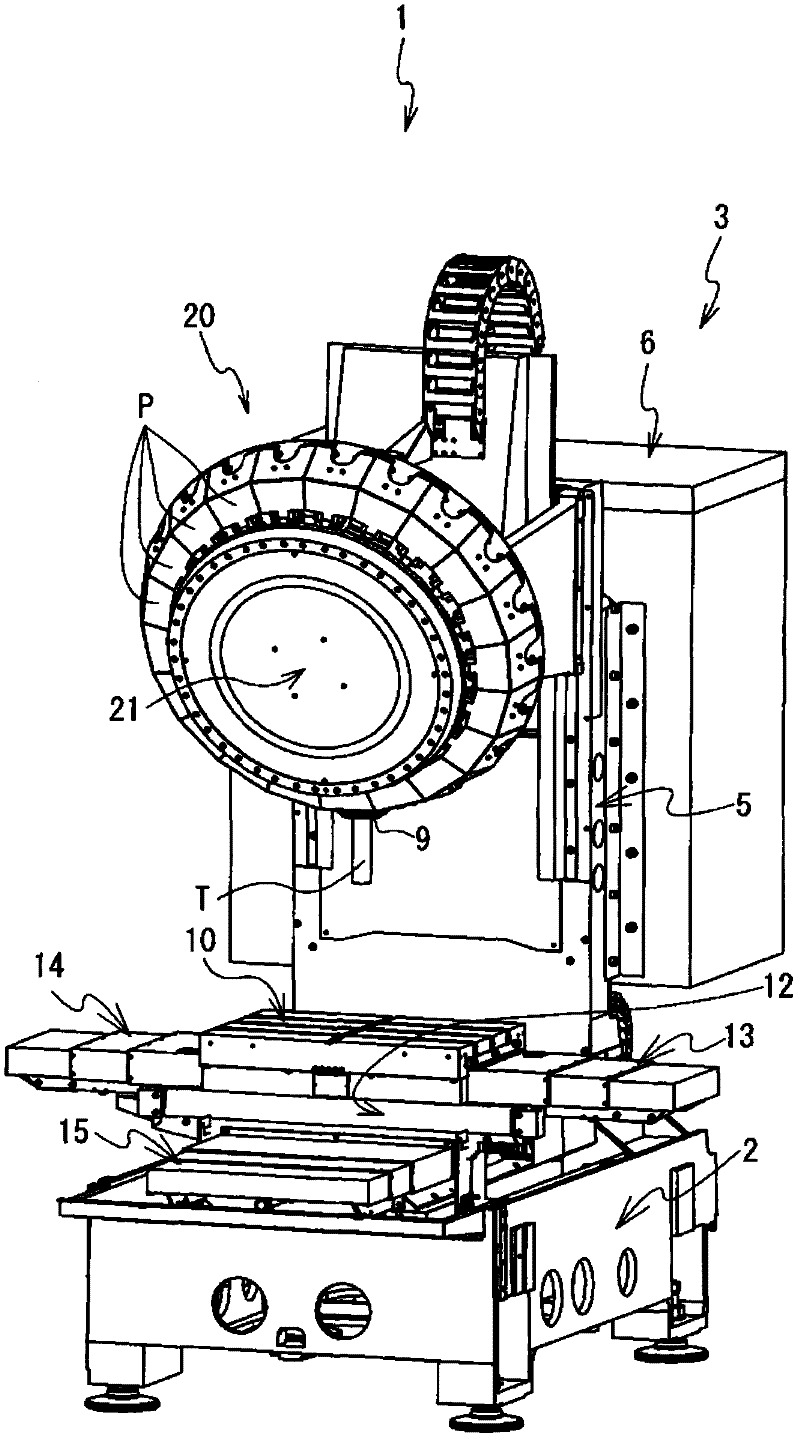

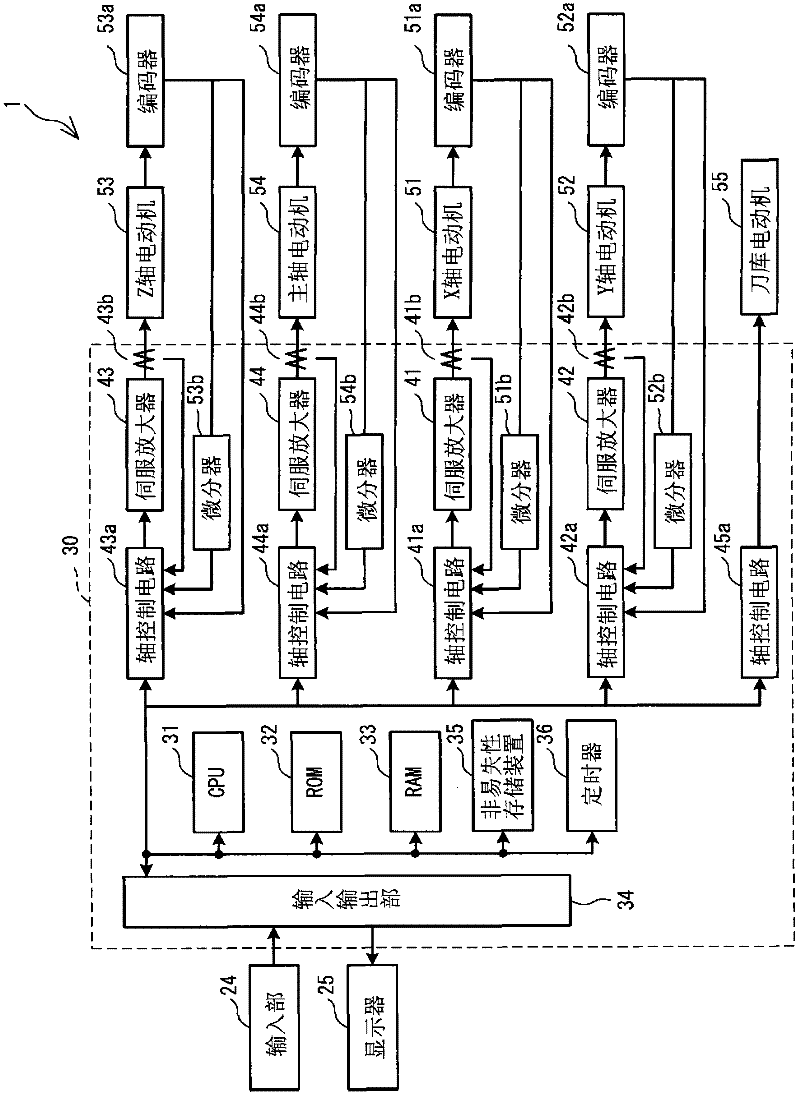

[0017] Embodiments of the present invention will be described below with reference to the drawings. figure 2 The numerical controller 30 is an embodiment of the present invention. The numerical controller 30 controls the machine tool 1 according to the processing program (refer to figure 1 ) axis movement, cutting action, tool change action, etc. The machine tool 1 cuts the workpiece by using the relative movement between the workpiece and the tool.

[0018] The structure of the machine tool 1 will be described. Such as figure 1 As shown, the machine tool 1 includes a base 2, a machine main body 3, a tool changer 20, and a protective cover (not shown). Base 2 is made of iron. The machine main body 3 is located on the upper part of the base 2 and is used for cutting the workpiece. The tool changing device 20 is located on the upper part of the machine main body 3 . The tool changing device 20 is used for changing the tool T installed on the main shaft 9 of the machine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com