Dust removal device for polishing of root ends of wind power generation blades

A technology for wind power generation blades and dust removal devices, which can be used in grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., and can solve the problems of human body suffering from respiratory diseases, hazards, and product scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

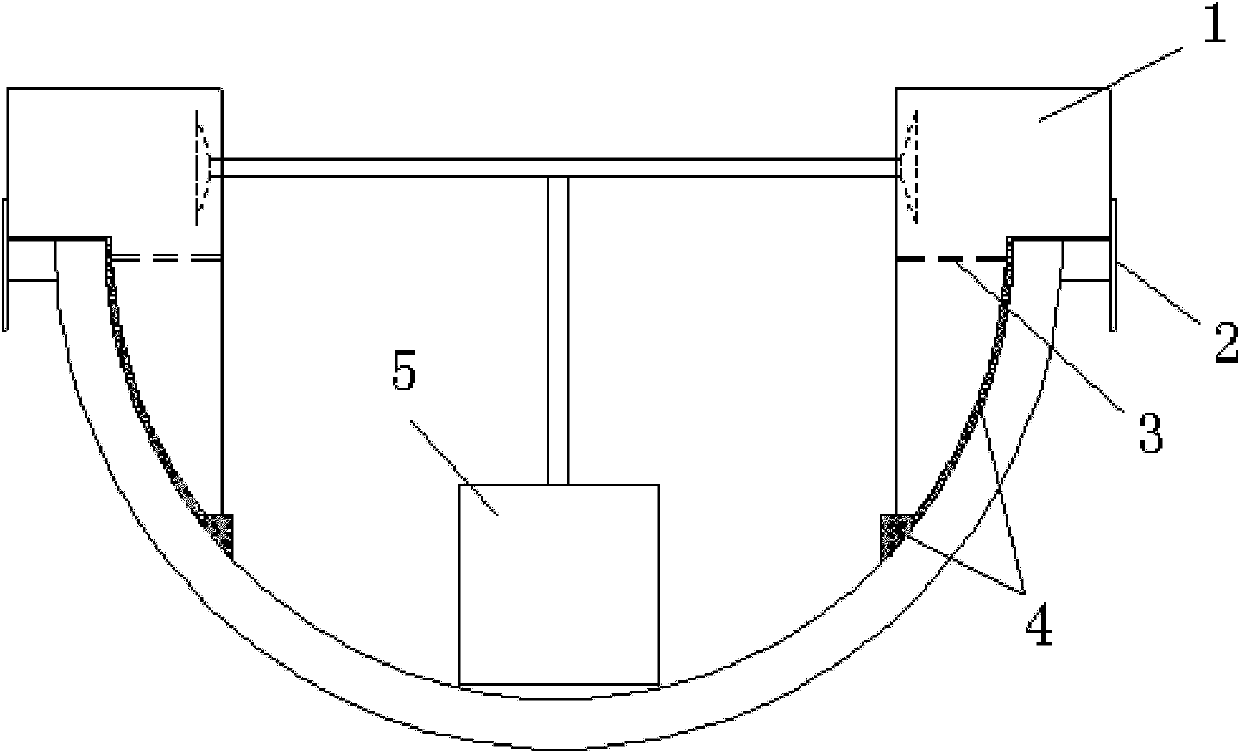

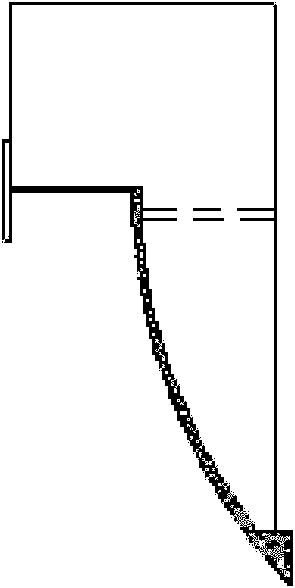

[0011] Depend on figure 1 , figure 2 , image 3 It can be seen that the present invention includes: a protective cover arranged at the grinding position of the root end of the blade; the protective cover includes: a dust removal cover 1 used to prevent the dust generated by grinding from flying away; Next to the position; a drawer-type baffle 3 to prevent dust from falling on the blade is placed under the dust cover 1; a sponge pad 4 with a conformal sealing effect is also included at the contact with the blade under the dust cover 1; The vacuum cleaner 5 used for dust removal is connected with the inside of the dust removal cover 1 .

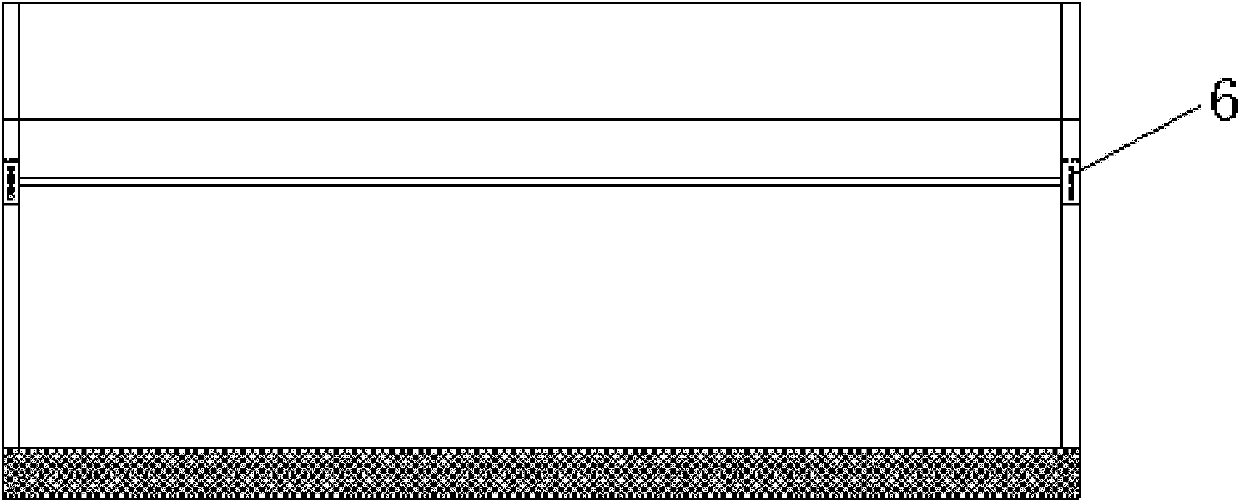

[0012] The fixing device 2 is a bolt; the bolt is inserted into the position-adjustable gear jack 6 .

[0013] The present invention adopts a drawer-type baffle for dust isolation, which is easy to assemble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com