Clean device of inner wall of rubber tube

A cleaning device and rubber tube technology, applied in drying equipment and cleaning fields, to improve processing efficiency, reduce labor costs, and avoid deformation and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

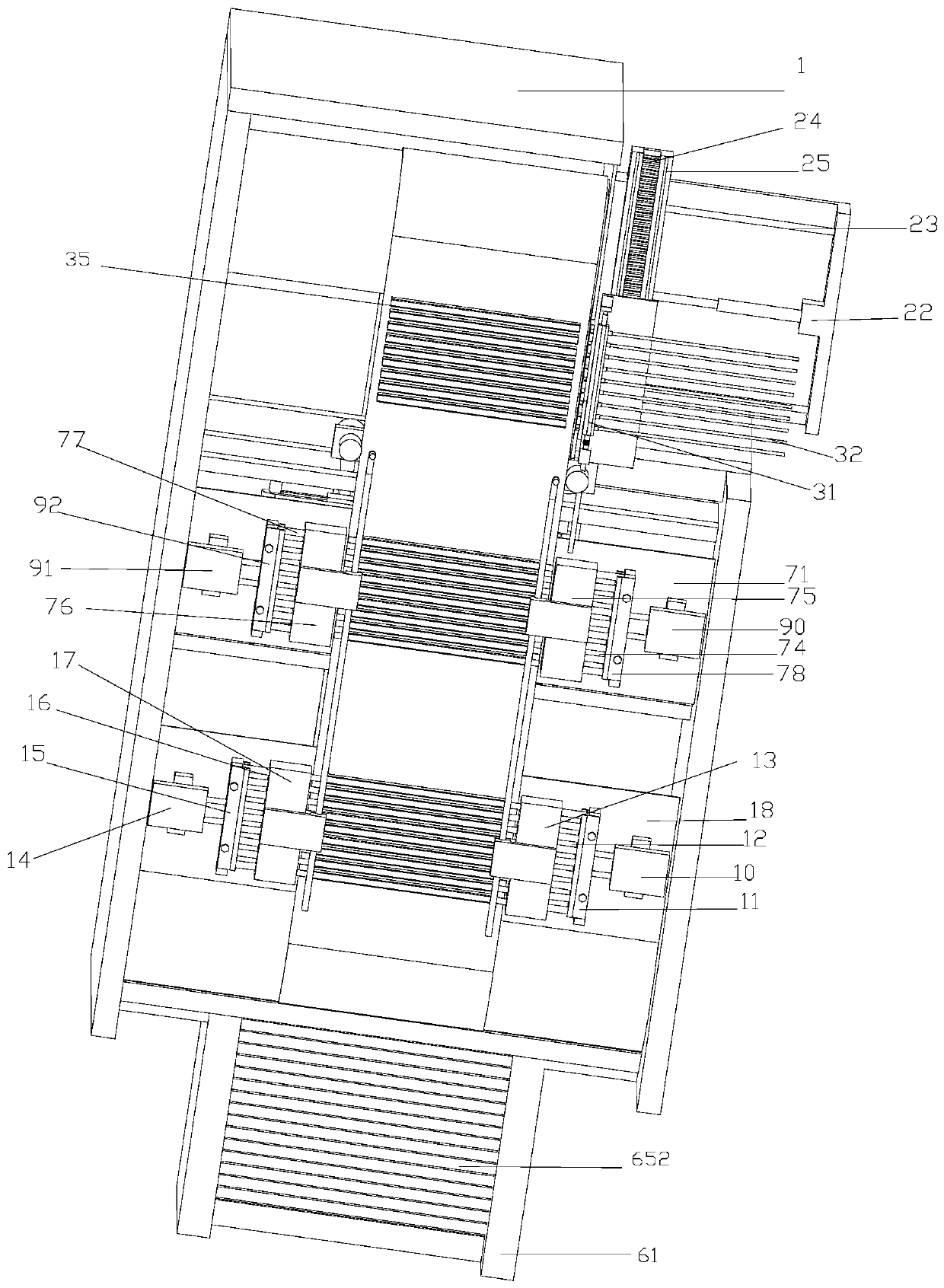

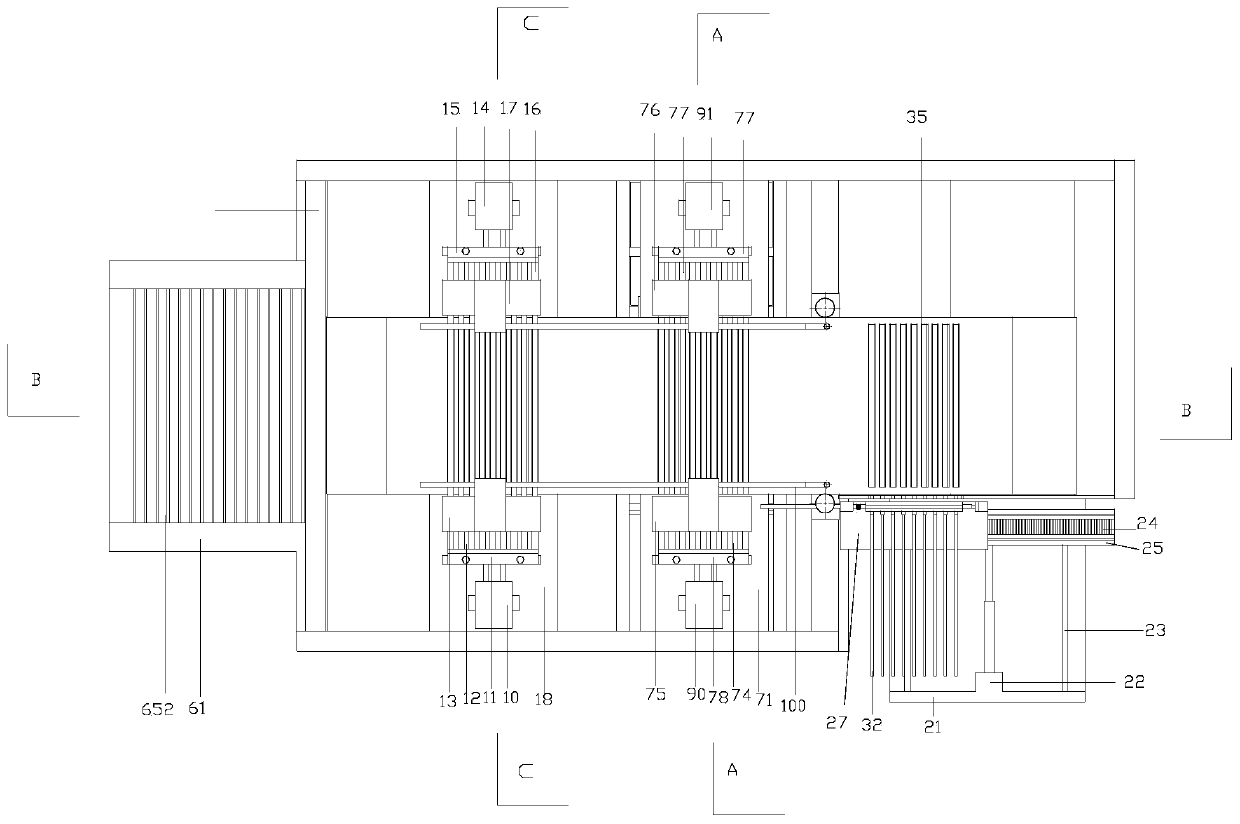

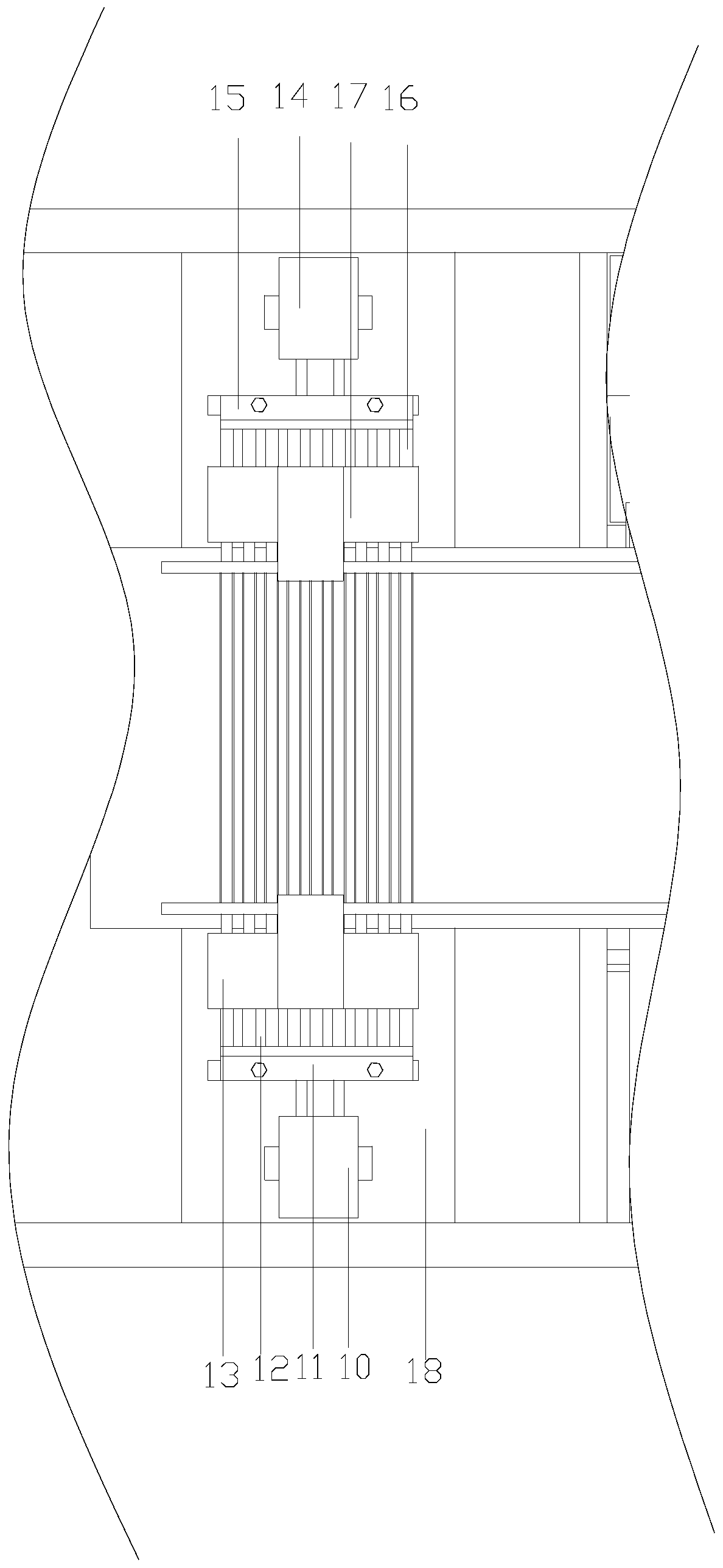

[0026] Such as Figure 1-12 As shown, a rubber tube inner wall cleaning device includes a frame 1, a cleaning device located in the frame 1, a drying device, a pick-up device, a feeding device, a discharging device, a compacting device and a sealing device; The sealing device includes a hollow cylinder 2, a rod body 3, a sealing member 4, and a reset member 5. The hollow cylinder 2 is sleeved in the air inlet pipe 12 and the water inlet pipe 74, and its outer wall cooperates with the inner wall of the pipe, and can move back and forth along the inner wall of the pipe. ; The seal 4 is a truncated plastic part with a rubber layer pasted on its surface, the rod body 3 is a stainless steel plate with a T-shaped structure, its thickness is 1CM, one end is welded with the hollow cylinder 2, and the other end is welded with the seal 4 Fixed connection, push the hollow cylinder 2 to move in the pipeline through the rubber tube to realize the seal 4 from the inlet and realize the openi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com