One-component epoxy encapsulating adhesive with good rheological stability and preparation method thereof

A single-component, epoxy-encapsulated technology, applied in the direction of epoxy resin adhesives, adhesives, adhesive types, etc., can solve problems such as changes in the rheological properties of the adhesive, exceeding the encapsulation range, and easy flow, etc., to achieve low elasticity modulus, reducing waste of resources, and reducing the effect of rework costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

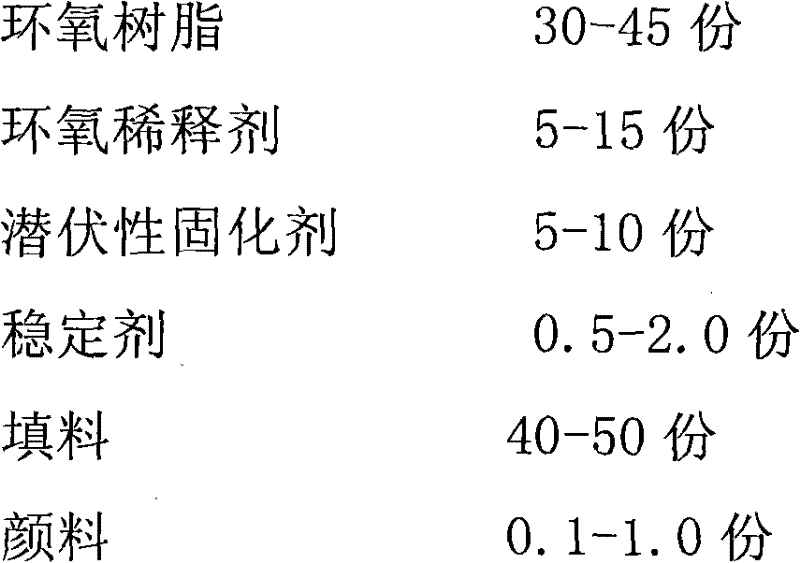

Method used

Image

Examples

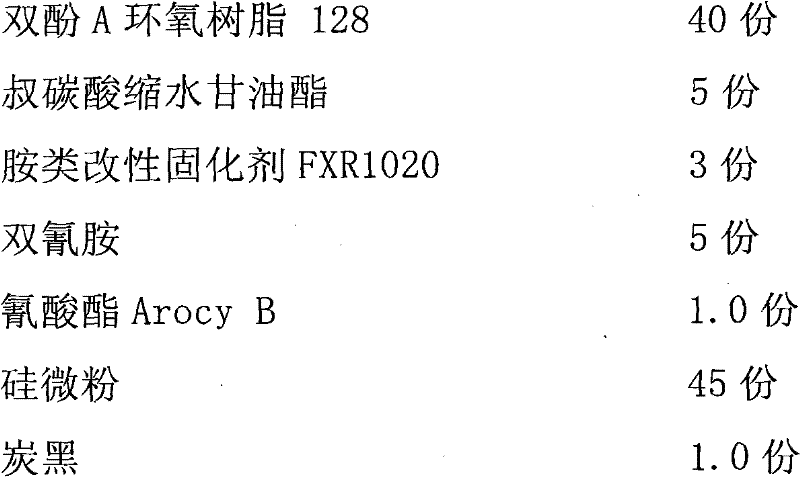

Embodiment 1

[0031]

[0032] Preparation method: Accurately weigh various raw materials according to the proportion of the above formula, first add epoxy resin, active diluent, and stabilizer to the reaction kettle in sequence, stir evenly under vacuum, then add fillers and pigments, after stirring evenly under vacuum, Add latent curing agent, disperse evenly, and carry out vacuum defoaming treatment.

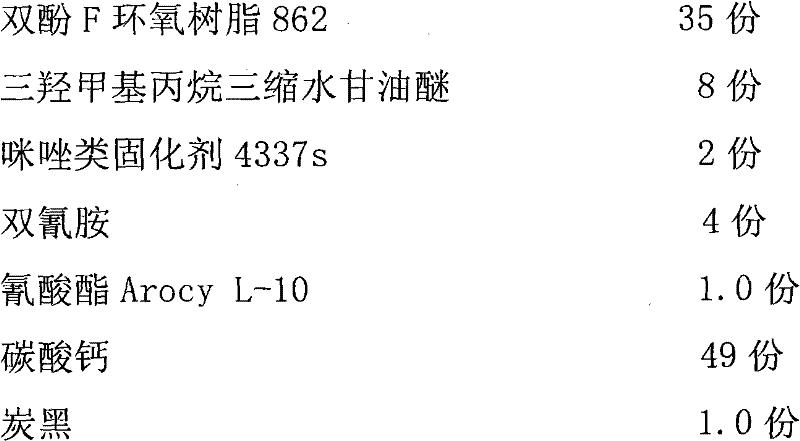

Embodiment 2

[0034]

[0035]

[0036] Preparation method: Accurately weigh various raw materials according to the proportion of the above formula, first add epoxy resin, active diluent, and stabilizer to the reaction kettle in sequence, stir evenly under vacuum, then add fillers and pigments, after stirring evenly under vacuum, Add latent curing agent, disperse evenly, and carry out vacuum defoaming treatment.

[0037] The embodiment listed in Table 1 and its curing characteristics and storage performance test results show that: the encapsulant of the present invention has low coefficient of linear thermal expansion, low modulus of elasticity, high bonding strength, good rheological stability, and long storage time. Convenience in production, use and storage.

[0038] Table 1

[0039]

[0040] The invention solves the rheological stability problem of storage at room temperature, adding cyanate ester stabilizers to the formula, and using the principle of addition of cyanate ester...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap