Group-cable tensioning process

A tensioning and crafting technology, applied in construction, building construction, processing of building materials, etc., can solve problems such as mutual influence and difficult control of cable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

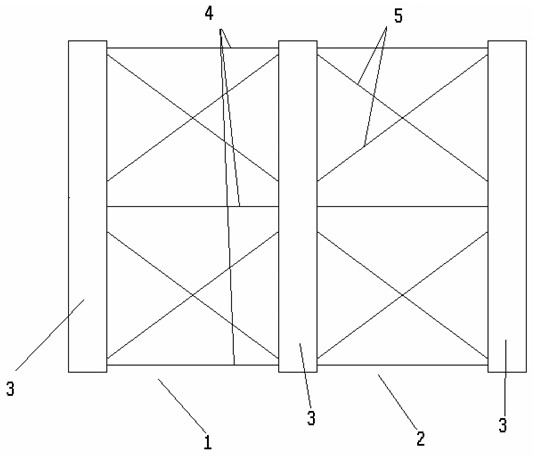

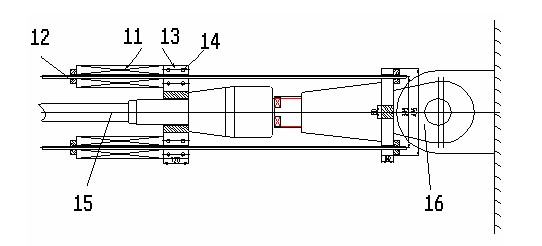

[0005] Below in conjunction with accompanying drawing and implementation example the utility model is described in detail.

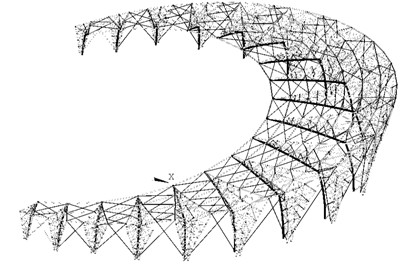

[0006] A group cable tensioning process is characterized in that: firstly calculate the stress on the cables to obtain the deformation arrays of the elastic deformations of all the cables, and perform cable tensioning according to the values in the elastic deformation deformation arrays of the cables during the tensioning construction process of the cables. After all the cables are stretched to the predetermined deformation, the overall structure is formed, which is characterized in that: the tensioning of the cables starts from the rigid structure in the middle, and then the tensioning of the cables is carried out symmetrically to the rigid structures on both sides pull.

[0007] The present invention mainly replaces the stress analysis of the original cable component by analyzing the elastic deformation of the cable component. The elastic deformatio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap