Steel and plastic composite bionic blade

A steel-plastic composite and blade technology, applied in the field of composite bionic blades, can solve problems such as the influence of generator working efficiency, slow blade rotation, weak impact force, etc., to achieve full and effective utilization of hydraulic resources, stable frequency, and increased rotational speed. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

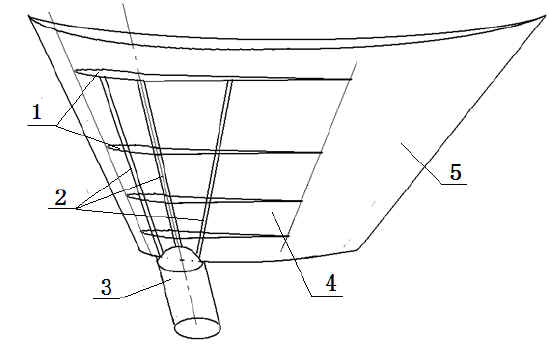

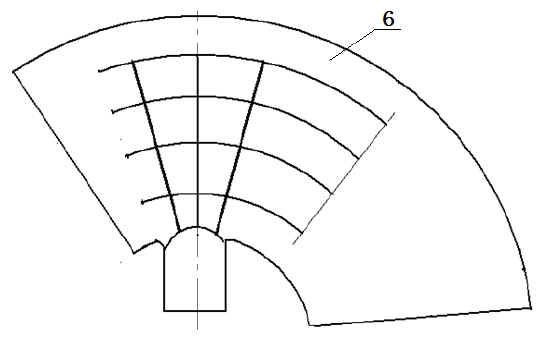

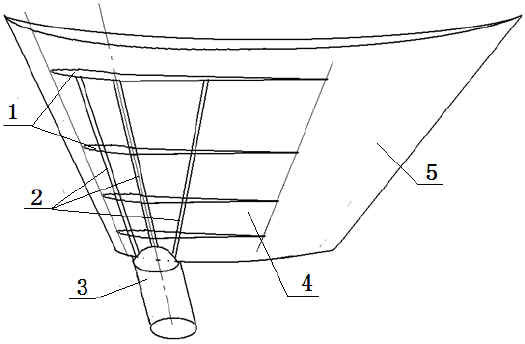

[0019] figure 1 Schematic diagram of the structure of the steel-plastic composite bionic blade provided by the embodiment of the present invention, figure 2 The steel-plastic composite bionic blade provided for the embodiment of the present invention is a schematic diagram of unfolding, and the steel-plastic elastic blade is expanded schematically 6, as shown in the figure: the steel-plastic composite bionic blade provided by the present invention includes blade 4, shaft 3 (or steel Seat) and the blade elastic area 5, the blade is a reinforced elastic blade 4 coated with plastic, the thickness of the blade changes from the middle to the edge in a streamlined shape, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com