Functional switching set of servo actuator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

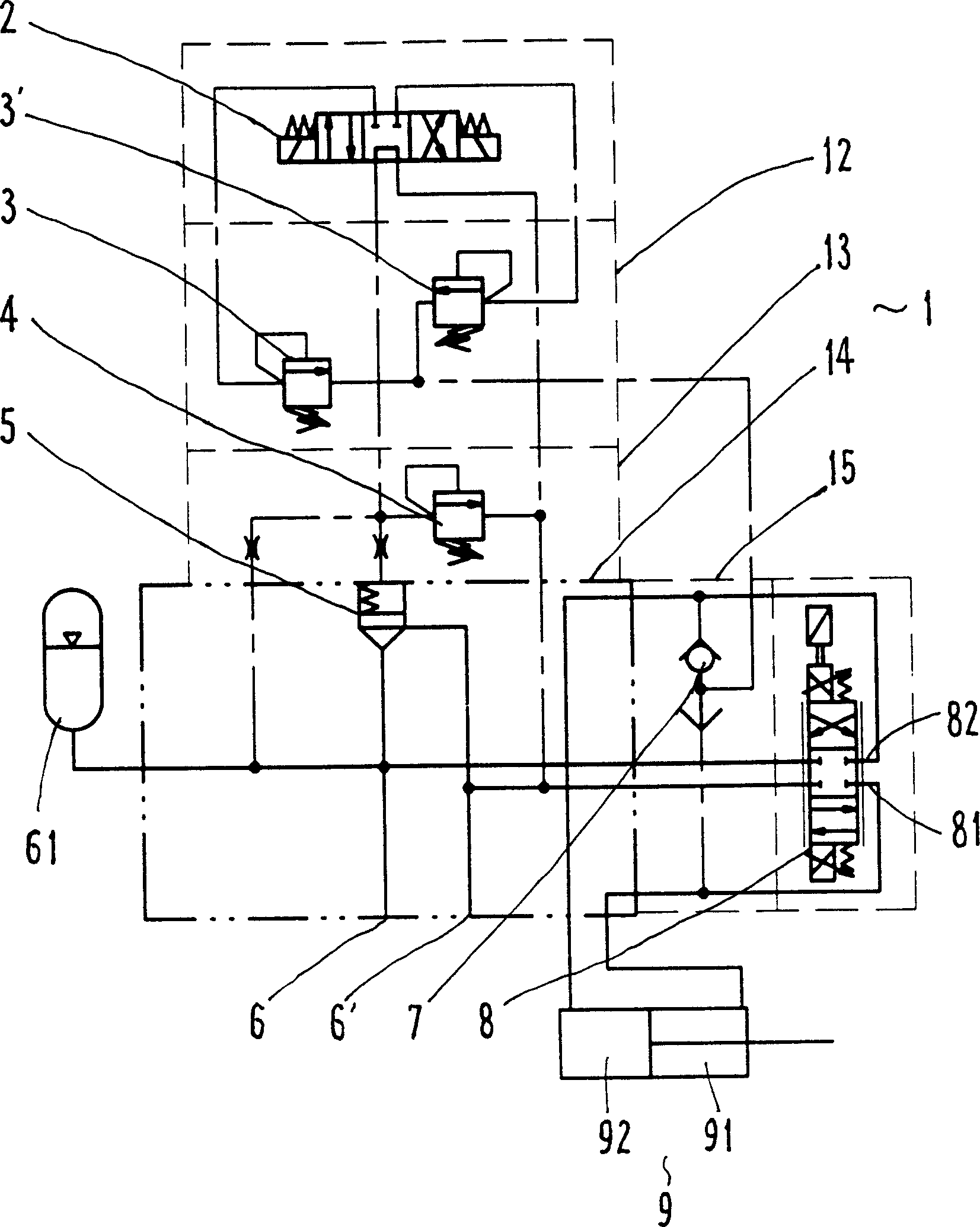

[0011] refer to figure 1 , the servo actuator function valve group is a combined valve block 1, which is composed of each valve block 12, 13, 14, 15, and each valve block 12, 13, 14, 15 is fixed as a whole with bolts, and its interior is provided with The flow passages of various valve parts can be connected, which can reduce the adverse influence of pipeline effects on the frequency response of the system.

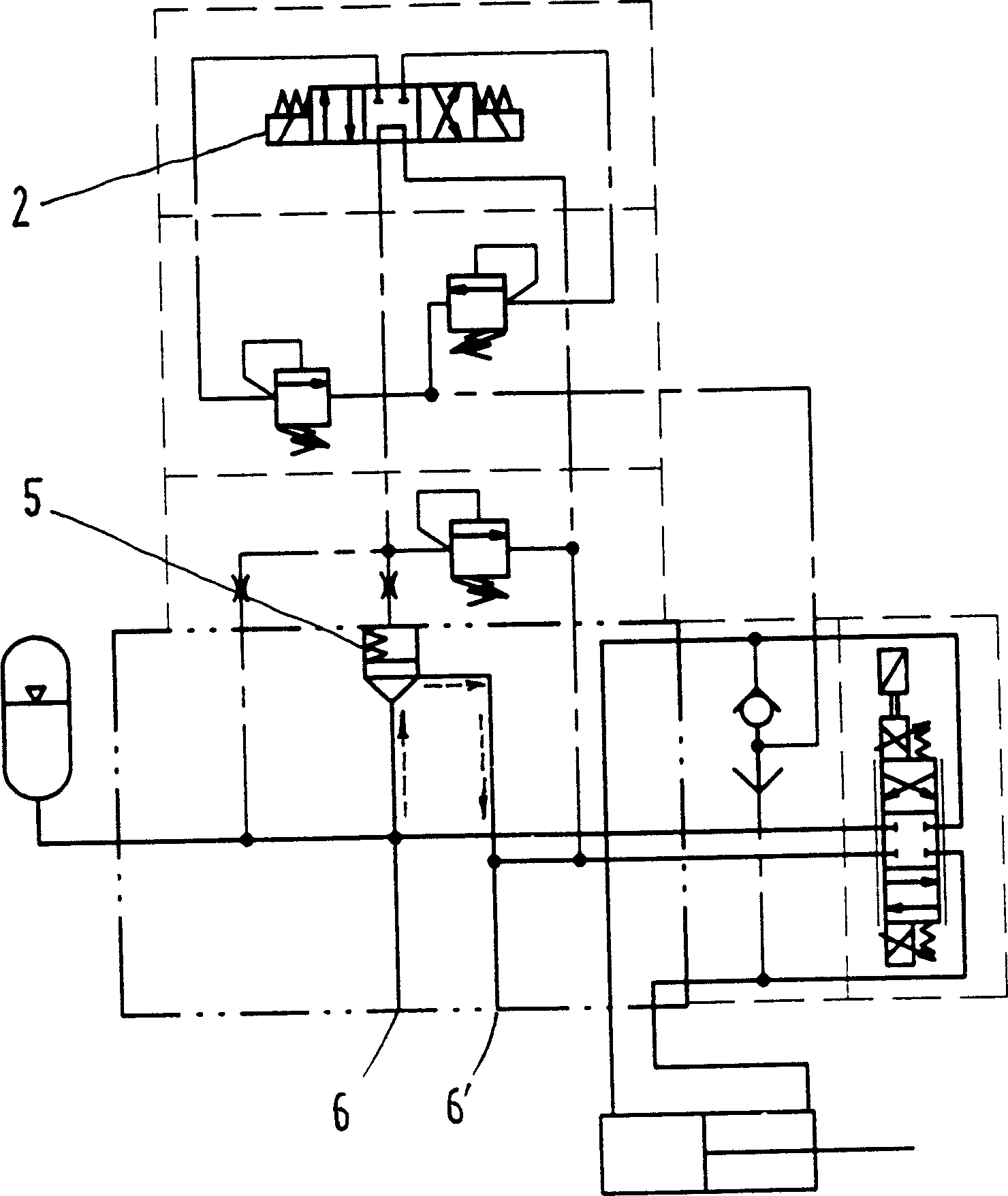

[0012] An electromagnetic reversing valve 2 is arranged on the valve block 12, and the electromagnetic reversing valve 2 is respectively connected with three overflow valves 3, 3', 4, pressure compensator 5 and oil return port 6', and the electromagnetic reversing valve 2 is a system Unloading valve and compensating pressure selection valve, when the valve is de-energized and in the neutral position, the entire flow of the system returns to the oil tank through the pressure compensator, such as figure 2 As shown by the dotted arrow, the unloading of low pressure and ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com