Non-contact valve plate flatness detection device and method

A flatness detection, non-contact technology, applied in measurement devices, mechanical measurement devices, optical devices, etc., can solve the problems of inability to meet the buyer's product quality inspection, inefficient detection methods, and poor reliability of detection results. Compact structure, high speed stability and small motion error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

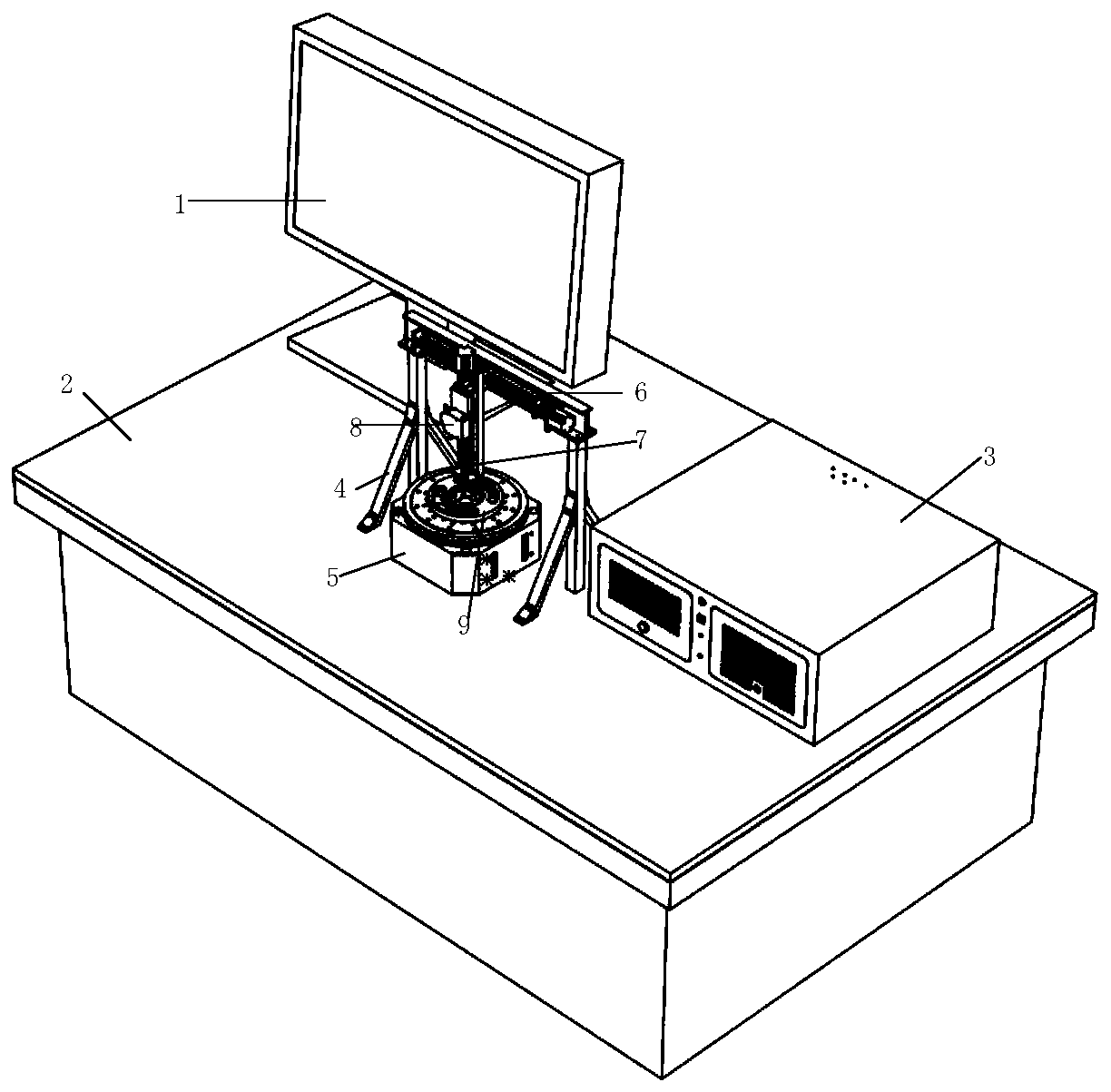

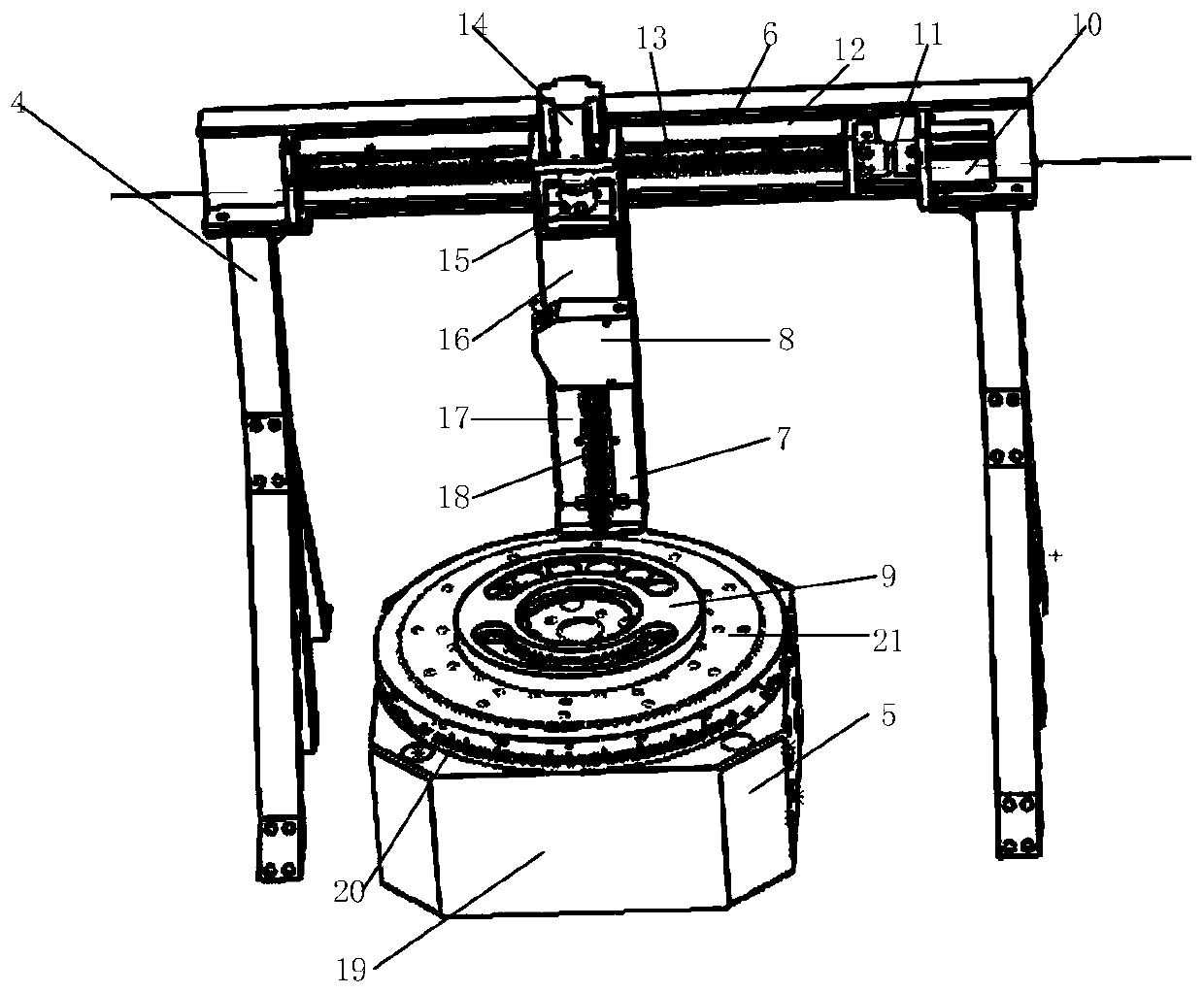

[0035] like figure 1 , 2As shown, the distribution plate 9 is placed on the air-floating turntable 5, the gantry 4 and the air-floating turntable 5 are placed on the marble table 2, the X-guiding rail is fixed on the gantry frame, and the Z-guiding rail is fixed on the X-guiding rail slider 13, the Z guide rail 7 slides with the X guide rail slider 13, and the laser displacement sensor 8 is installed on the Z guide rail connecting plate 16, through the Z direction motor 14 and the Z direction coupling 15, along with the Z guide rail slider 16 Swipe up and down. The industrial computer 3 controls the corresponding motors 10 and 14 by controlling the motion control card, and then controls the movement of the X guide rail, the Z guide rail and the air bearing turntable.

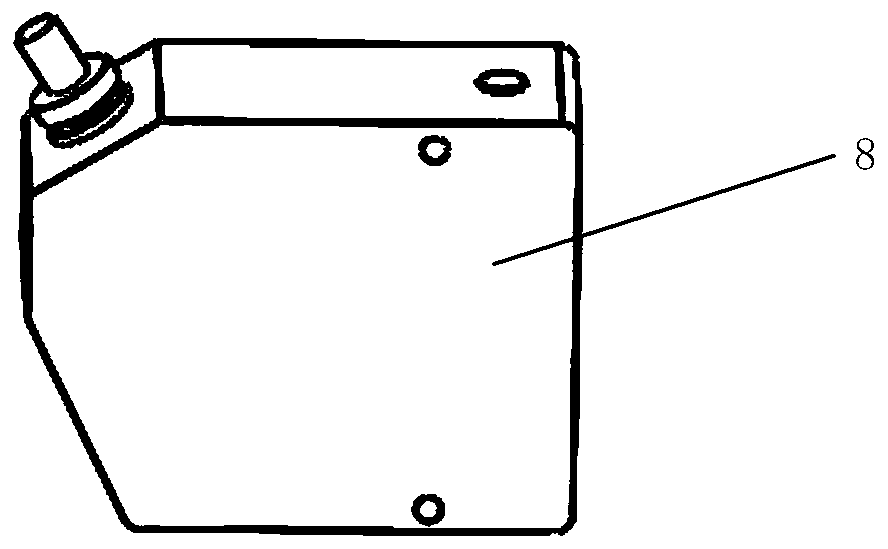

[0036] like image 3 As shown, the general structure of the laser displacement sensor is shown in the figure, and the measurement accuracy is 0.2 μm.

[0037] like Figure 4 As shown, the test bench and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com