gear

A gear and tooth surface technology applied to gears. It can solve the problems of limited gear volume, short service life of amorphous alloys, and high use costs of amorphous alloys, so as to avoid machining and improve hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

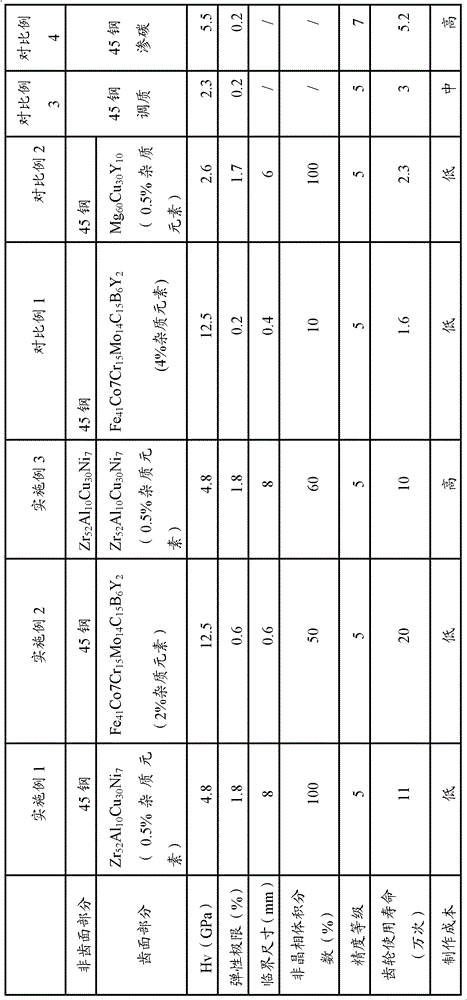

Embodiment 1

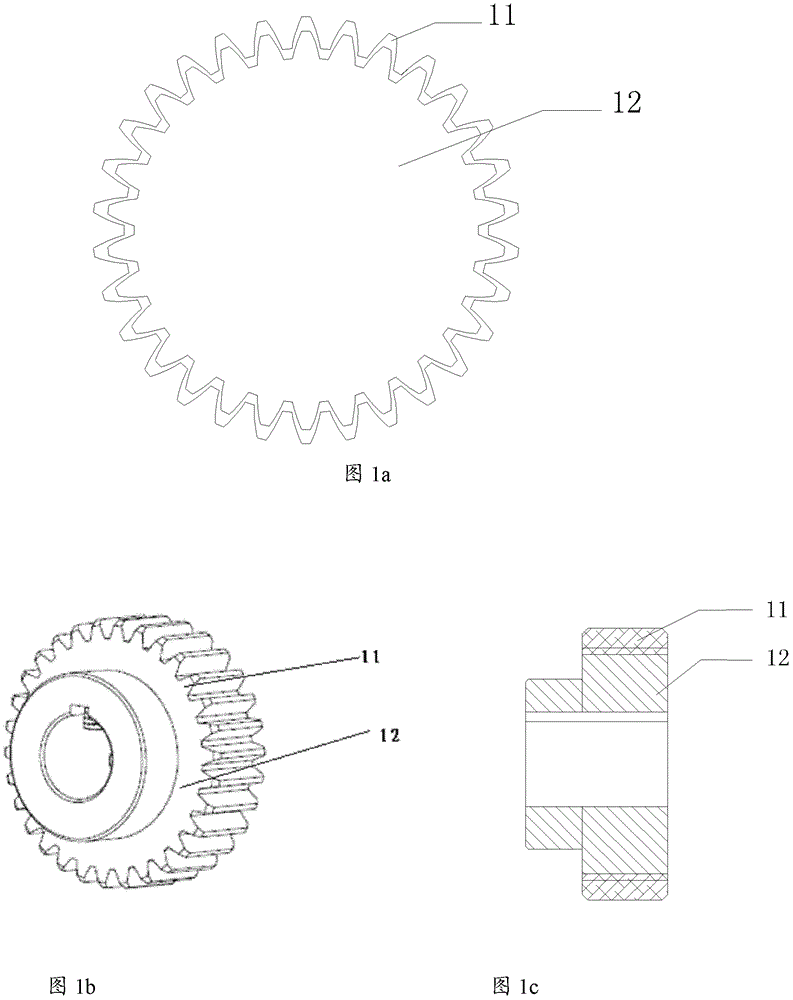

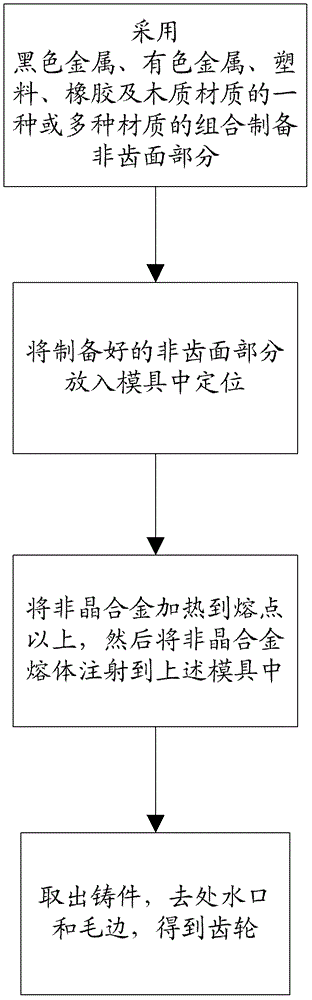

[0050] First, use 45-gauge steel to prepare the non-tooth surface portion. Specifically, blanking, punching, machining, and quenching and tempering are sequentially performed to obtain figure 1 The non-toothed portion 12 in the gear shown in .

[0051] Then, the prepared non-tooth surface portion is placed in a die-casting mold and positioned.

[0052] Next, the amorphous alloy Zr 52 Al 10 Cu 30 Ni 7 Heated to above the melting point, the superheat is 200 degrees Celsius, and protected by inert gas, and then Zr 52 Al 10 Cu 30 Ni 7 The melt is injected into the above-mentioned mold, thereby coating the tooth surface portion 11 formed of the amorphous alloy on the outside of the non-tooth surface portion 12 .

[0053] Finally, the casting is taken out, the nozzle and the burrs are removed, and the tooth shape is finely ground to obtain the gear of the embodiment of the present invention.

Embodiment 2

[0055] Except that the amorphous alloy material used is Fe 41 Co 7 Cr 15 Mo 14 C 15 B 6 Y 2 The gears were prepared in the same manner as in Example 1 except for (containing 2 at% of impurity elements).

Embodiment 3

[0057] The amorphous alloy Zr 52 Al 10 Cu 30 Ni 7 Heated to above the melting point, the superheat is 200 degrees Celsius, and protected by inert gas, and then Zr 52 Al 10 Cu 30 Ni 7 The melt is injected into a die-casting mold to form gears made entirely of amorphous alloys.

[0058] Finally, the casting is taken out, the nozzle and the burrs are removed, and then the tooth shape is finely ground to obtain the gear of the embodiment of the present invention.

[0059] In addition, for comparison, the above-mentioned gears were also prepared according to the following method using conventional materials, conventional processes and techniques other than the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com