Construction method for patching of refractory materials of furnace top of heating furnace

A construction method and heating furnace technology, applied in the direction of lining repair, etc., can solve problems such as long shutdown time, inability to repair furnace top refractory materials, and inability to effectively solve problems, and achieve the effect of saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

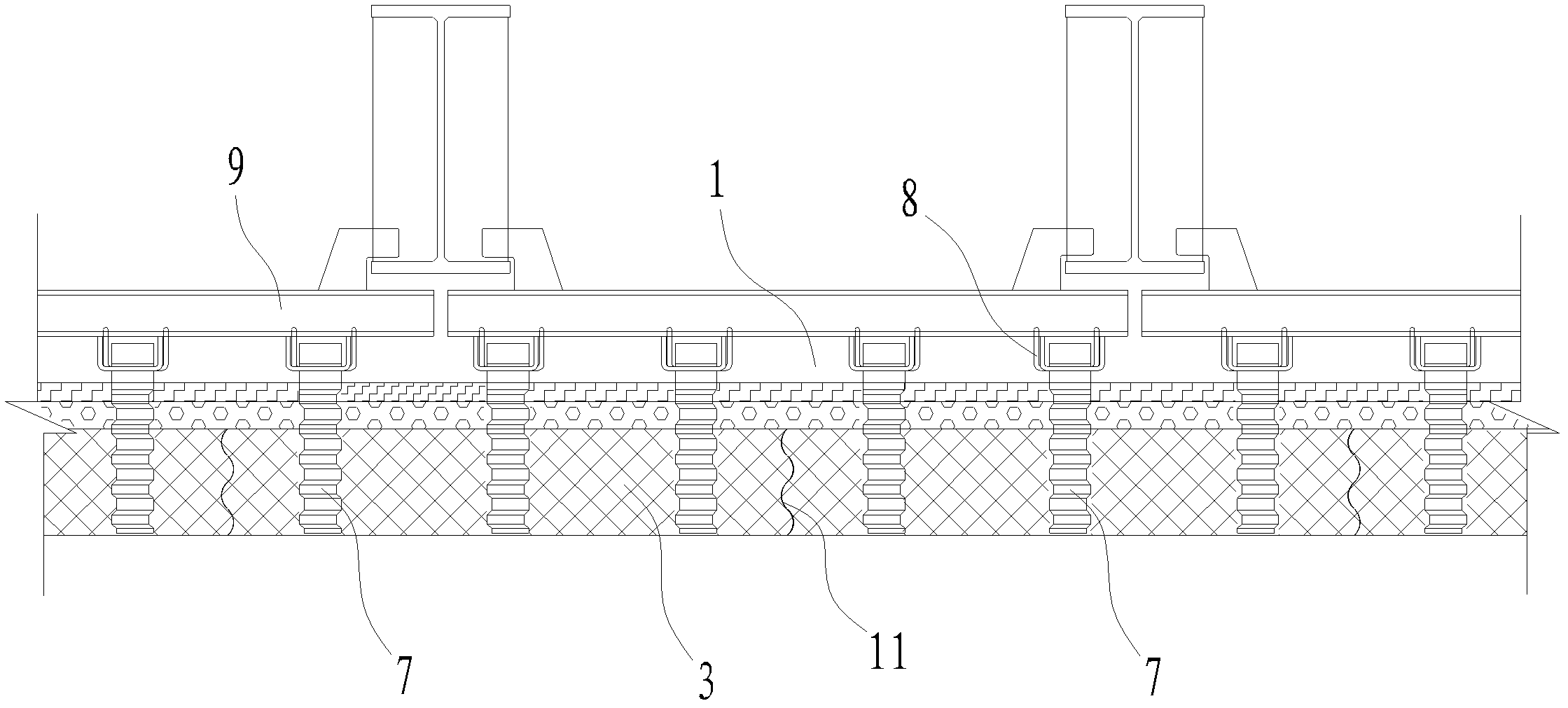

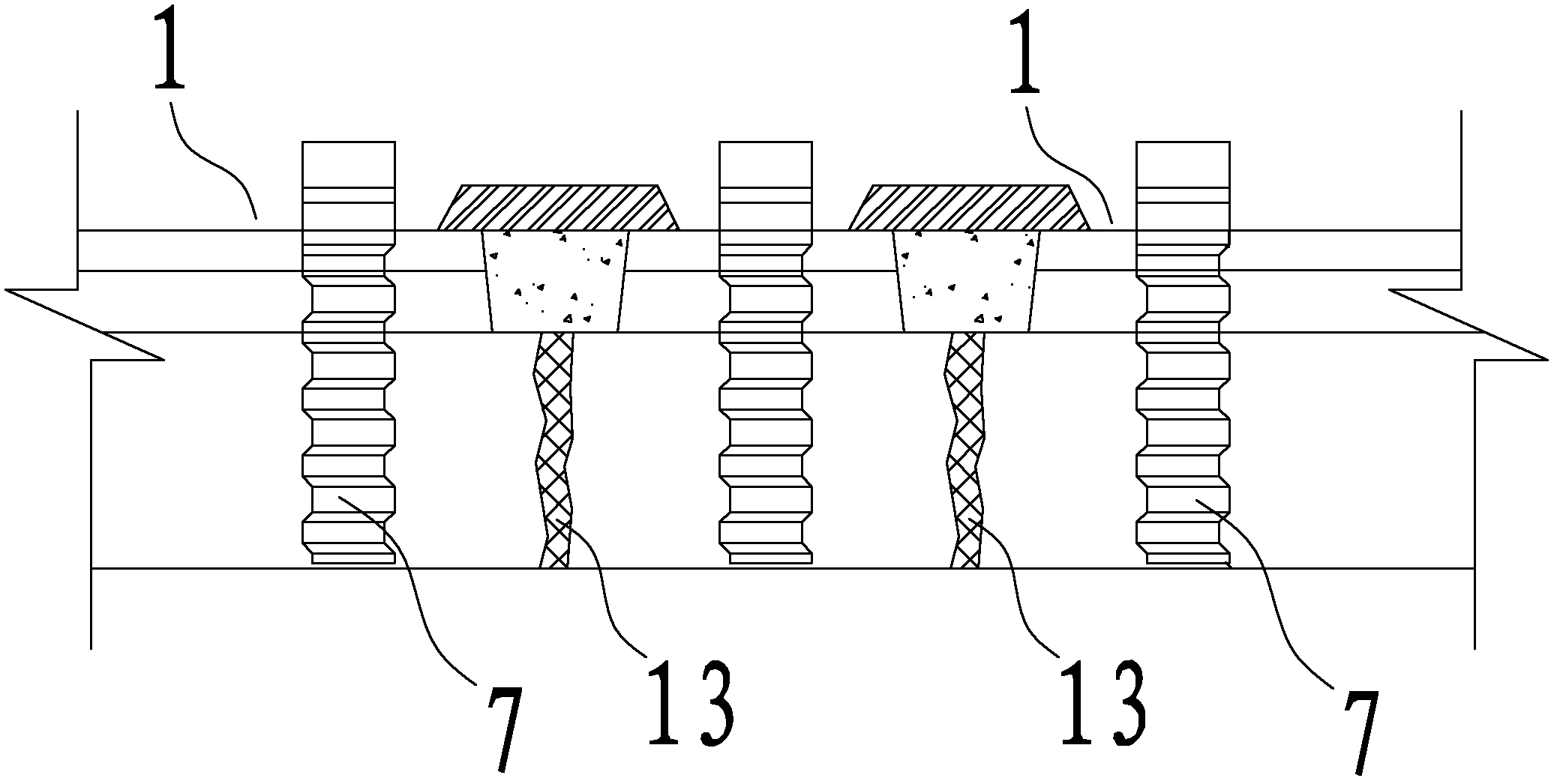

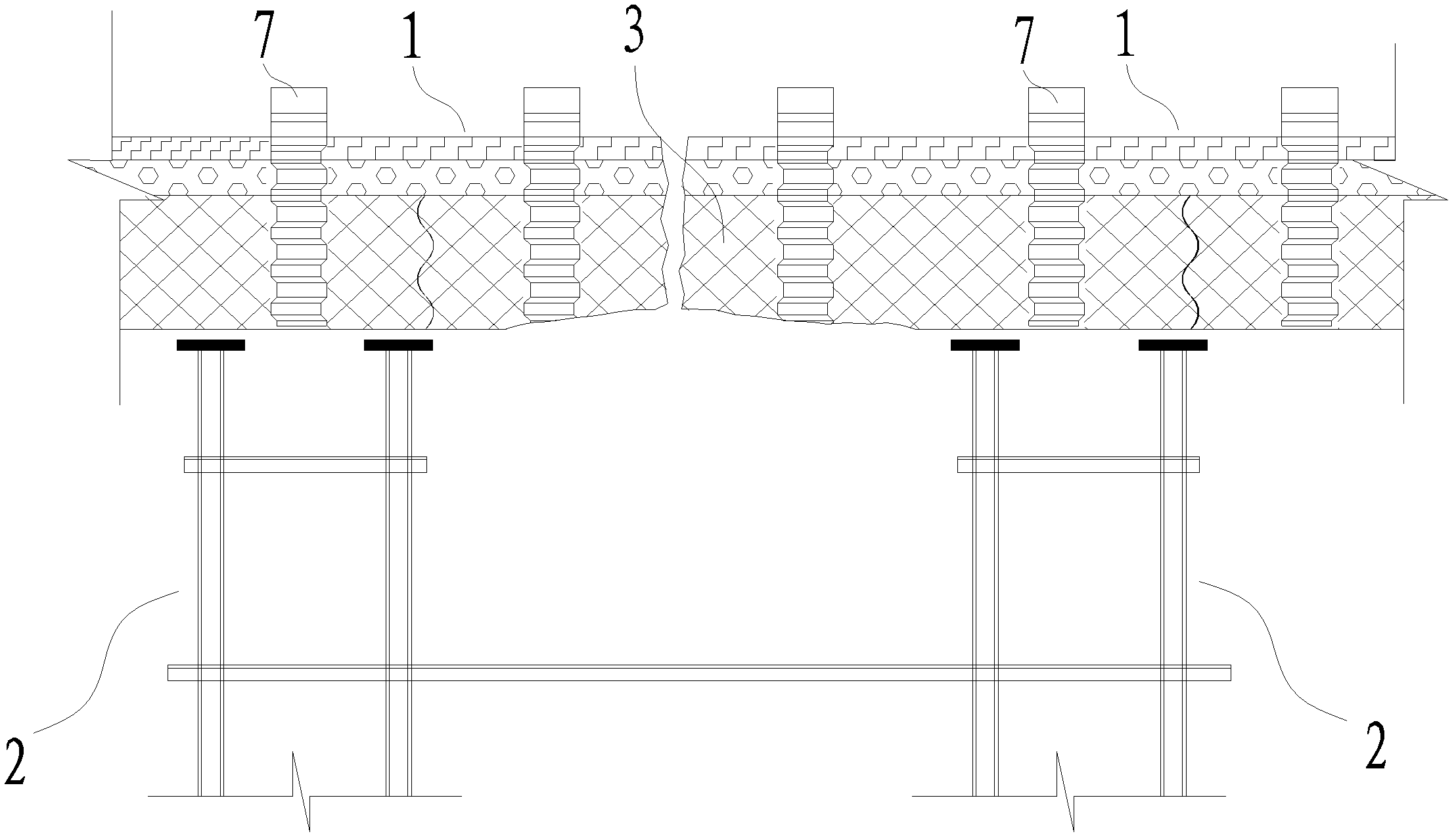

[0030] Such as Figure 3 to Figure 7 Shown is a low investment cost provided by the present invention, long service life after the completion of the construction method for digging and repairing refractory materials on the top of the heating furnace. The construction method includes the following steps,

[0031] 1) Stop the furnace and lower the furnace temperature below 45 degrees;

[0032] 2) Erection of a furnace roof support frame, in the furnace, erect a furnace roof support frame 2 for the area of the furnace roof that needs to be repaired, to firmly support the furnace roof 1;

[0033] 3) Chiseling and repairing the slope surface, chiseling off the furnace roof refractory material 3 that needs to be repaired due to cracking and falling off, and forming a repairing slope surface 4 around the repair area;

[0034] 4) formwork support, under the furnace roof 1 where the furnace roof refractory material 3 is chiseled and the repair slope surface 4 is formed, the pouring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com