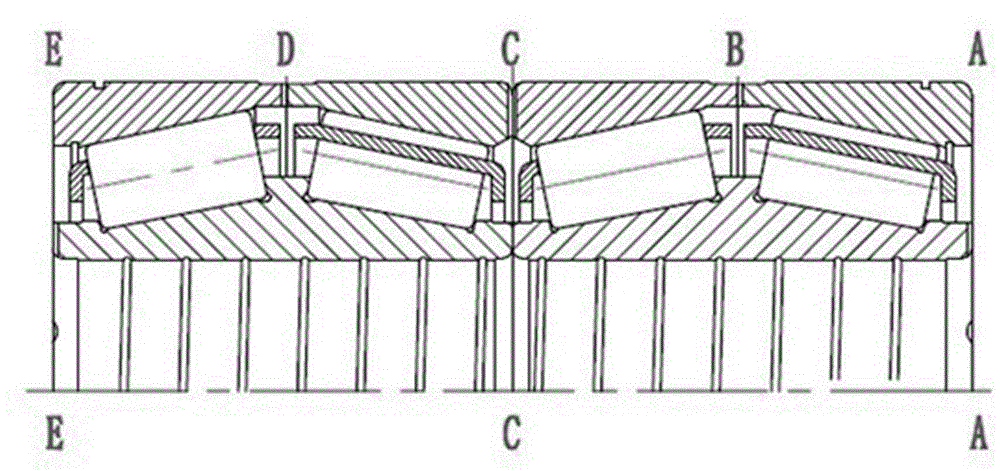

Method for fitting and measuring axial clearance of spacer-free four-column tapered roller bearing

A tapered roller bearing, axial clearance technology, applied in measuring devices, instruments, etc., can solve the problems of large human error, many parts, and no mature measurement methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A combined measurement method for the axial clearance of four-row tapered roller bearings without a spacer, including the following steps:

[0032] Step 1: Set the dimensional tolerance of the outer ring AB and ED end faces as a, the outer ring BC and DC end face dimensional tolerance as b, the inner ring end face dimensional tolerance as c, and the clearance as A ~ B.

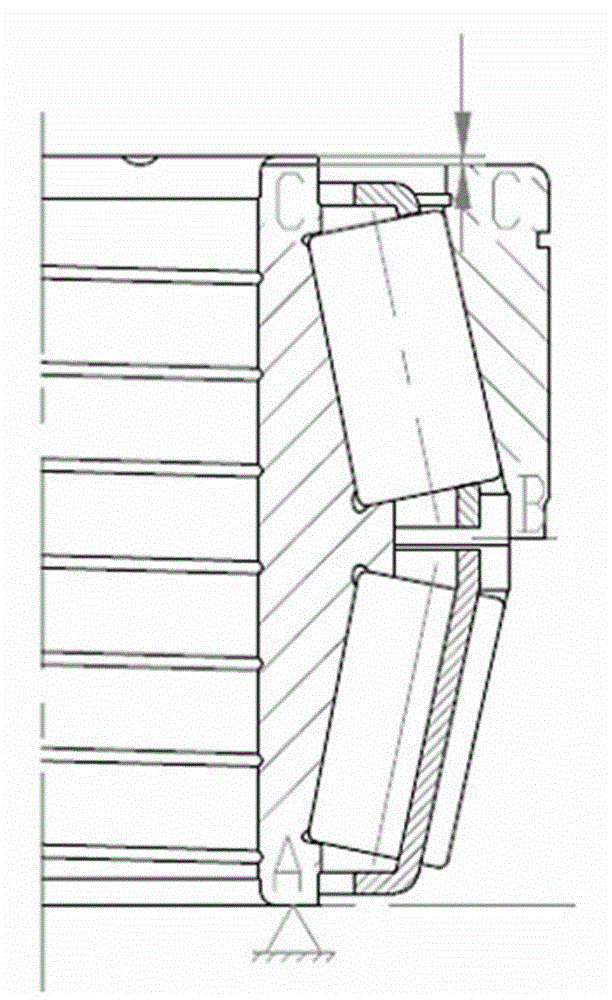

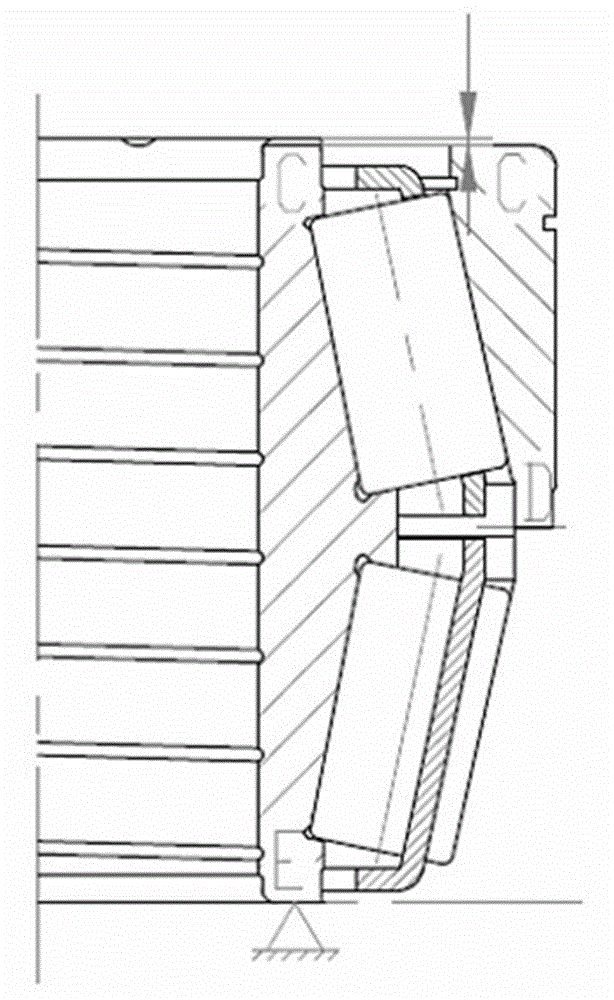

[0033] Step two:

[0034] First, measure the C surface of the inner ring, the A surface of the inner ring and the E surface of the inner ring;

[0035] Taking the end face of the inner ring as the reference zero position, measure that the end face of the outer ring is lower than the end face of the inner ring A / 2 ~ B / 2, namely -A / 2 ~ -B / 2.

[0036] If the measured value is greater than -A / 2, under the condition of ensuring the assembly height, grind the end face C of the outer ring to -A / 2 ~ -B / 2;

[0037] If the measured value is less than -B / 2, grind the end surface C of the inner ring to -A / 2 ~ -B / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com