Multi-type universal coaxial dynamometer bench for engine

An engine and dynamometer technology, applied in the field of dynamometer benches, can solve the problems of difficulty in ensuring the coaxiality of the engine, the installation size is not adjustable, and the space occupied, etc., and achieves low input cost, convenient height adjustment, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

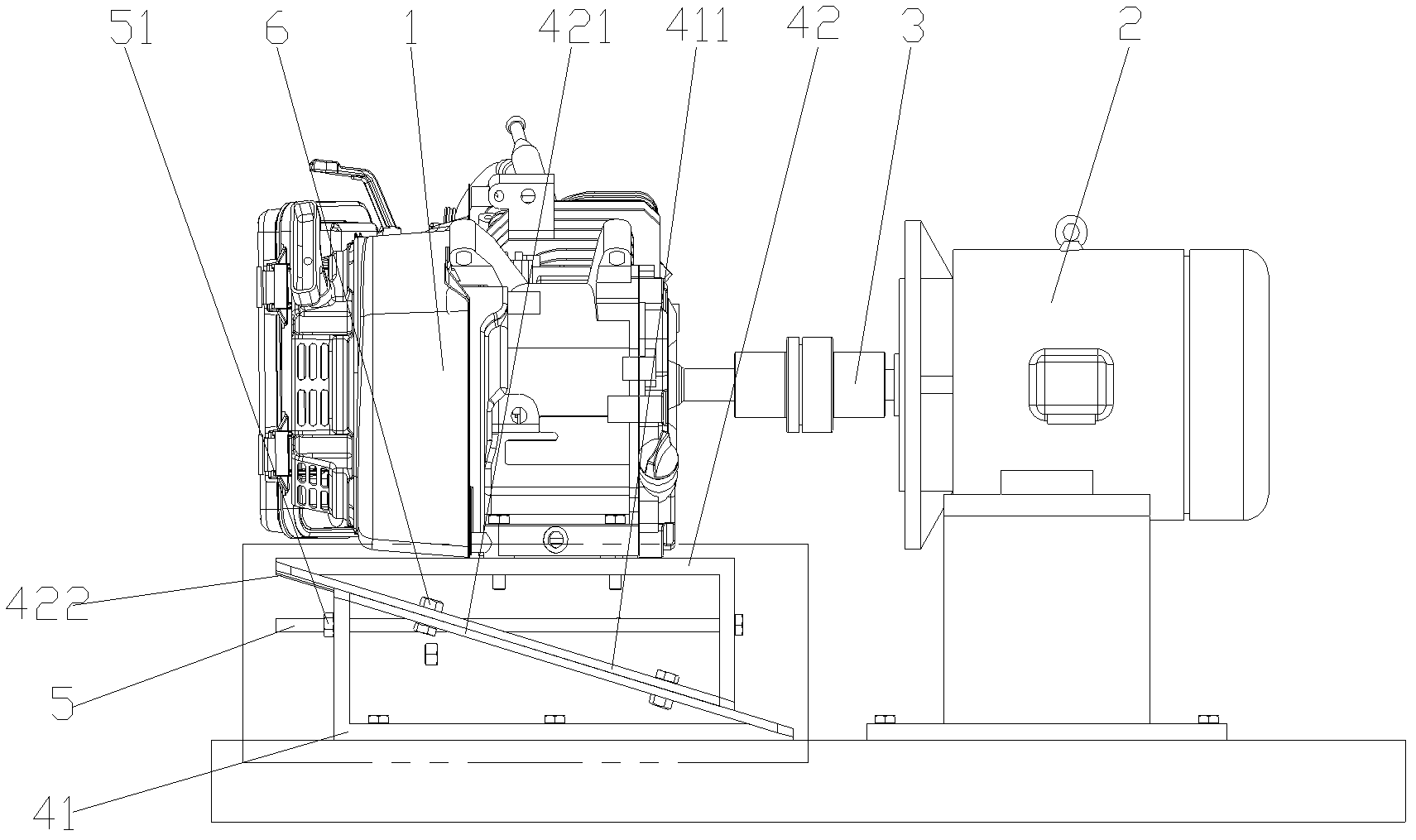

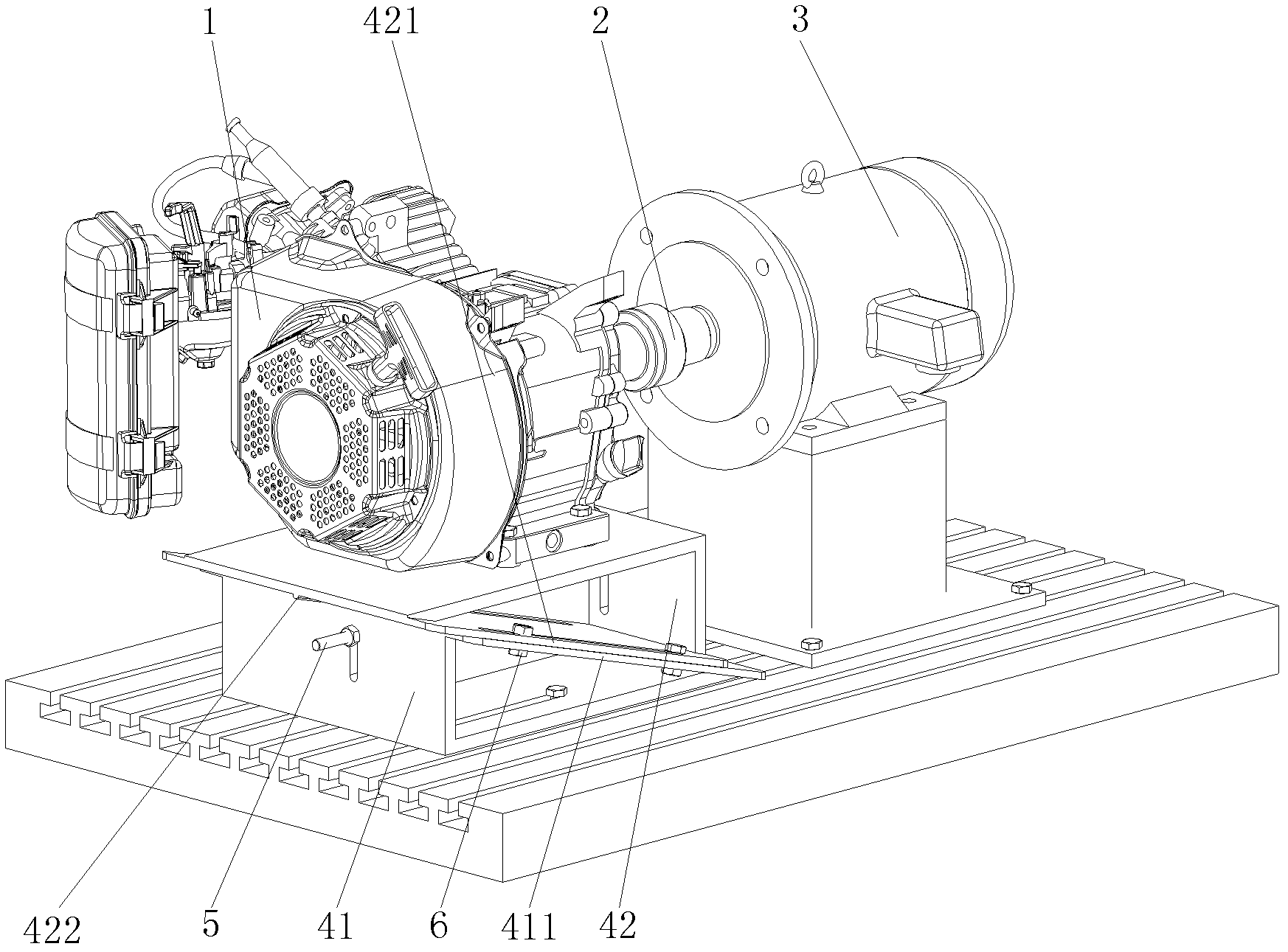

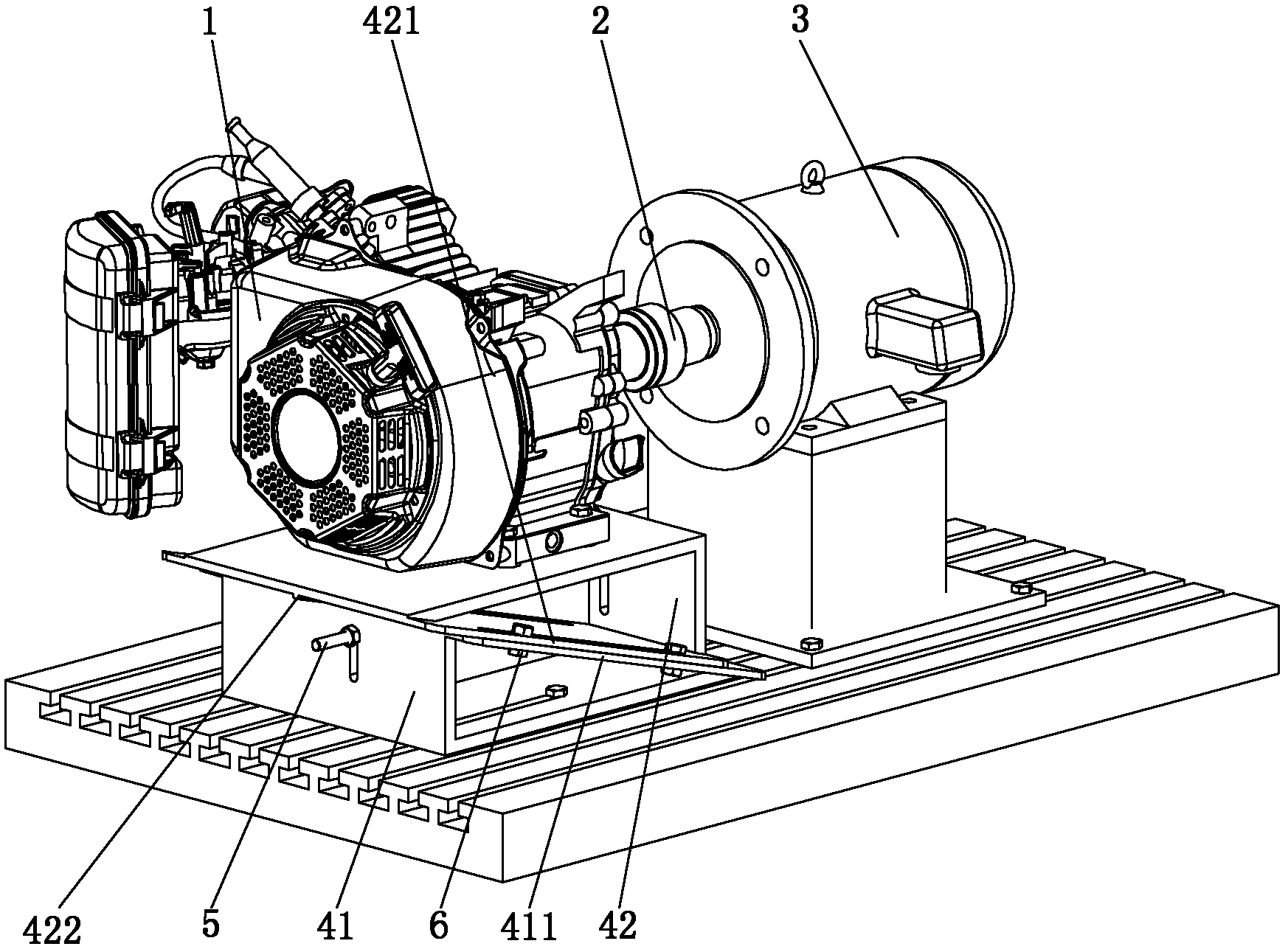

[0010] Such as figure 1 or figure 2 As shown, the multi-model universal coaxial dynamometer bench of the present invention includes a dynamometer 1 and an engine 2, and the dynamometer 1 is connected with the engine 2 by a shaft coupling 3, and it also includes a dynamometer The supporting platform 4, the dynamometer 1 is fixed on the dynamometer supporting platform 4, the dynamometer supporting platform 4 includes two right-angled triangular platforms 41 and 42 with the same inclination angle, and one of the triangular platforms 42 is reversed by its slope 421 On the inclined plane 411 of another triangular stand 41, two inclined planes 411, 421 are provided with more than three screw holes, and the two inclined planes 411, 421 are fixed by more than three screws 6, wherein the inverted triangular stand 42 is formed by The guide rail 422 on the slope 421 slides along the slope 411 of the other triangular stand 41 .

[0011] The two triangular stands 41, 42 are transversely...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap