Method of and apparatus for detecting cracks in piezoelectric element

A piezoelectric element and detection unit technology, applied in the measurement of electrical variables, measurement devices, material analysis by electromagnetic means, etc. Piezoelectric element cracks and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described with reference to the drawings. Each embodiment applies a voltage at the resonant frequency of the piezoelectric element through the electrodes, the piezoelectric element is interposed between the electrodes, the dielectric loss tangent between the electrodes is measured under the applied voltage, and according to the measured dielectric Loss tangent, detects whether the piezoelectric element has one or more cracks (hereinafter simply referred to as "cracks").

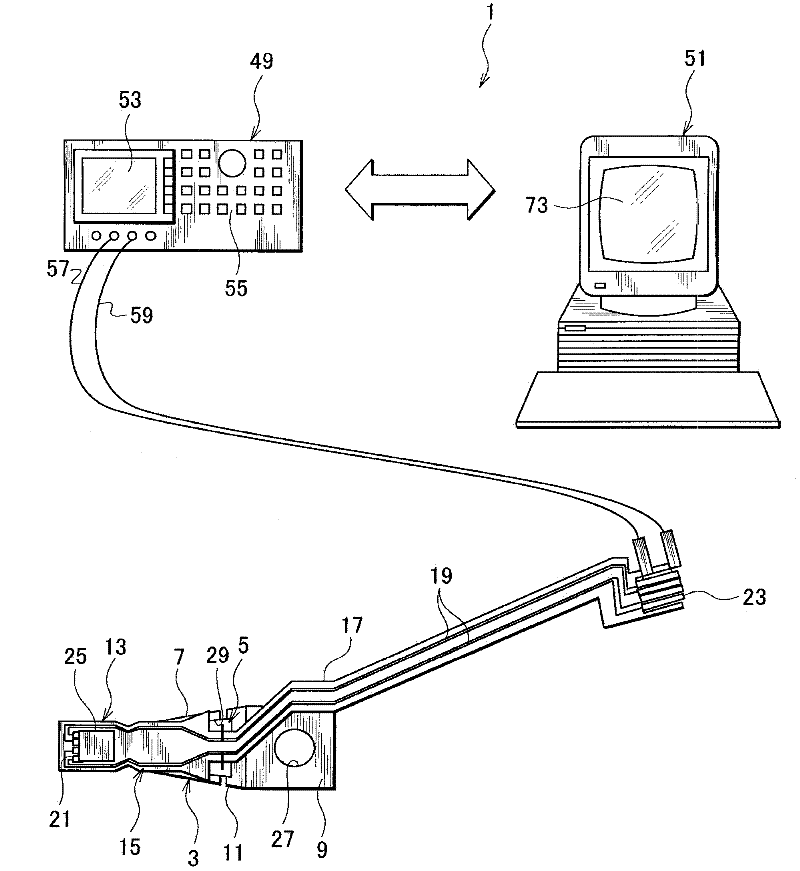

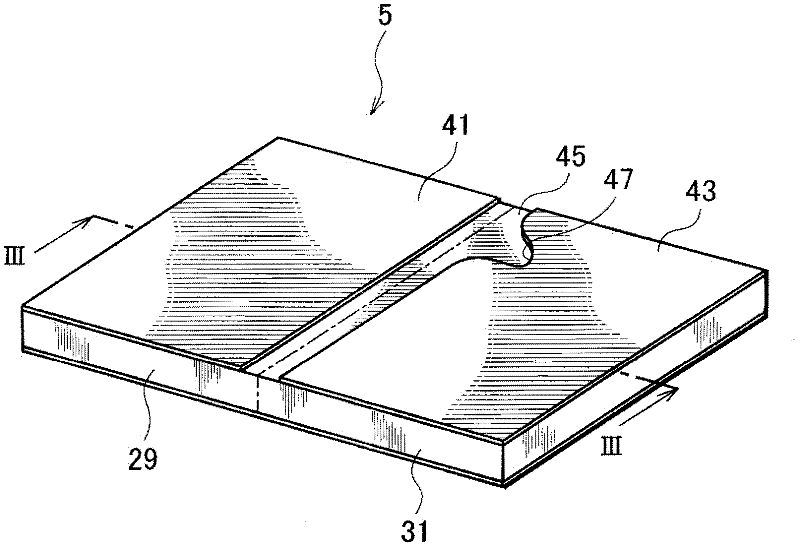

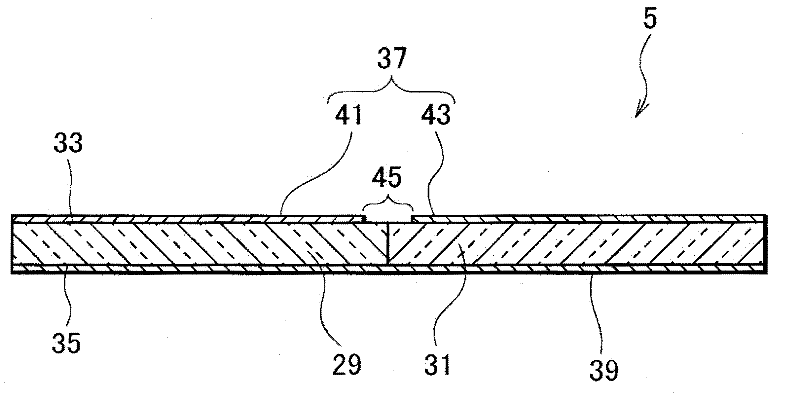

[0031] figure 1 is a schematic view showing the apparatus for detecting a crack in a piezoelectric element and the head suspension 3 according to the first embodiment of the present invention.

[0032] figure 1 , the crack detection apparatus 1 detects whether or not the piezoelectric element 5 fitted in the head suspension 3 has a crack. First, examples of the piezoelectric element 5 and the head suspension 3 will be described.

[0033] The head suspens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com