Lithium ion battery and manufacturing method thereof

A technology of lithium-ion batteries and manufacturing methods, which is applied in the manufacture of electrolyte batteries, secondary batteries, final product manufacturing, etc., can solve the problems of increasing the production cost of lithium-ion batteries, wasting aluminum-plastic films, etc., and achieve the elimination of aluminum-plastic films, Improved safety and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

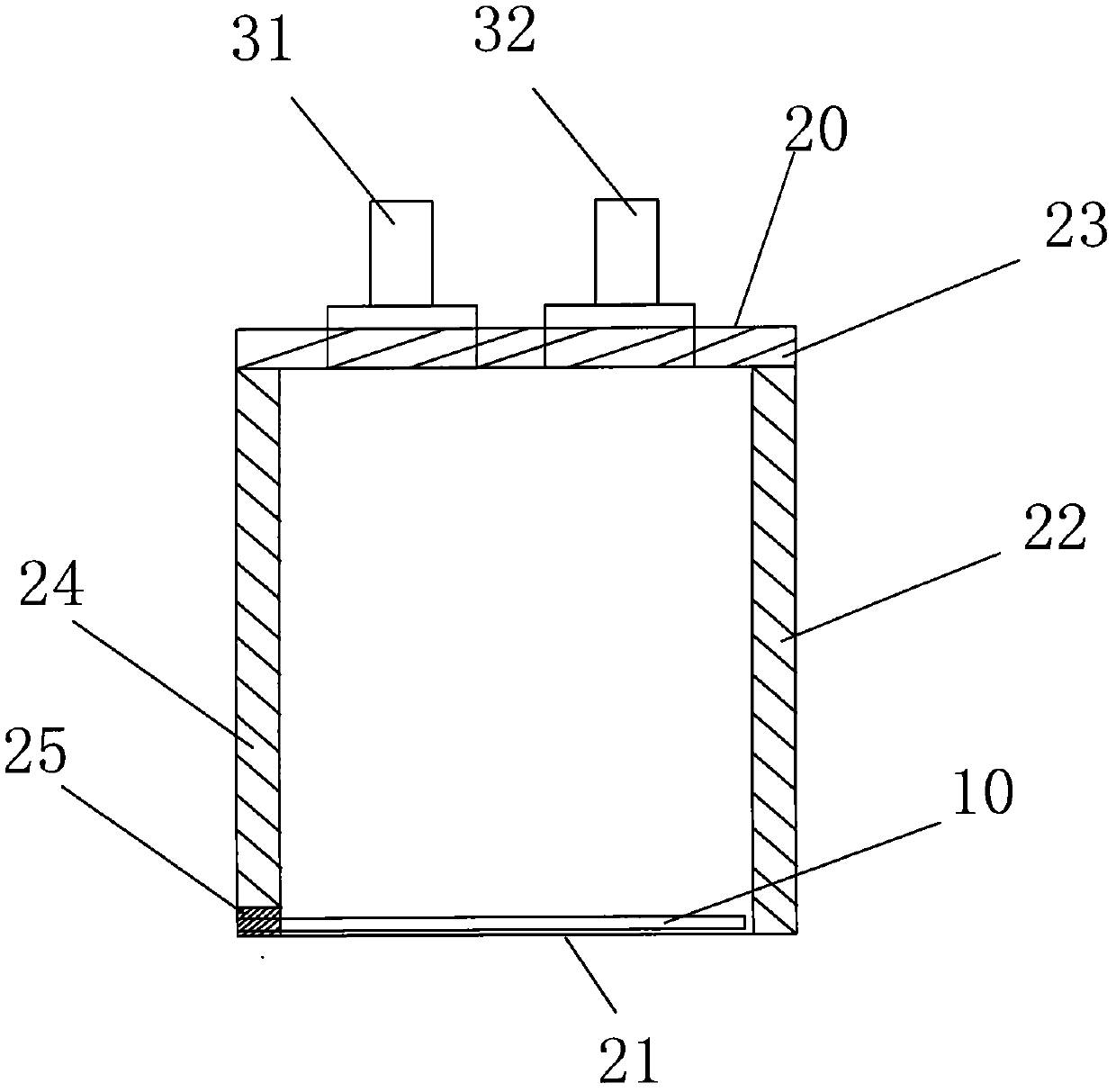

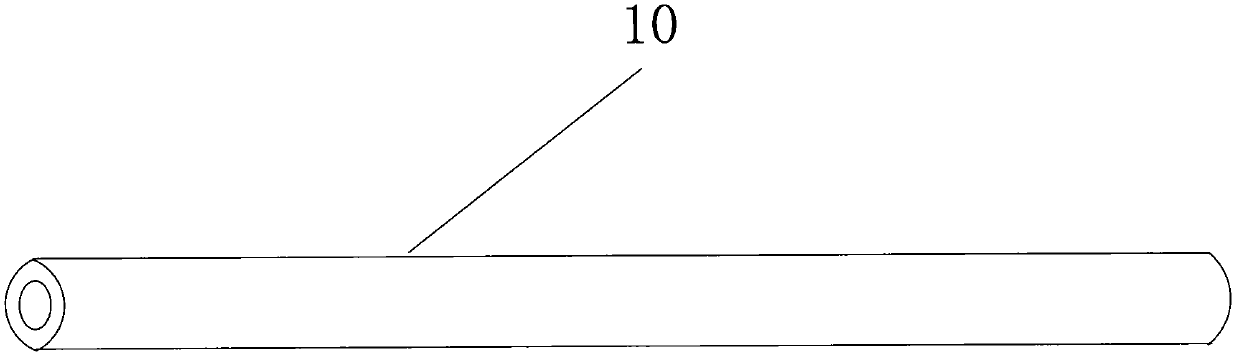

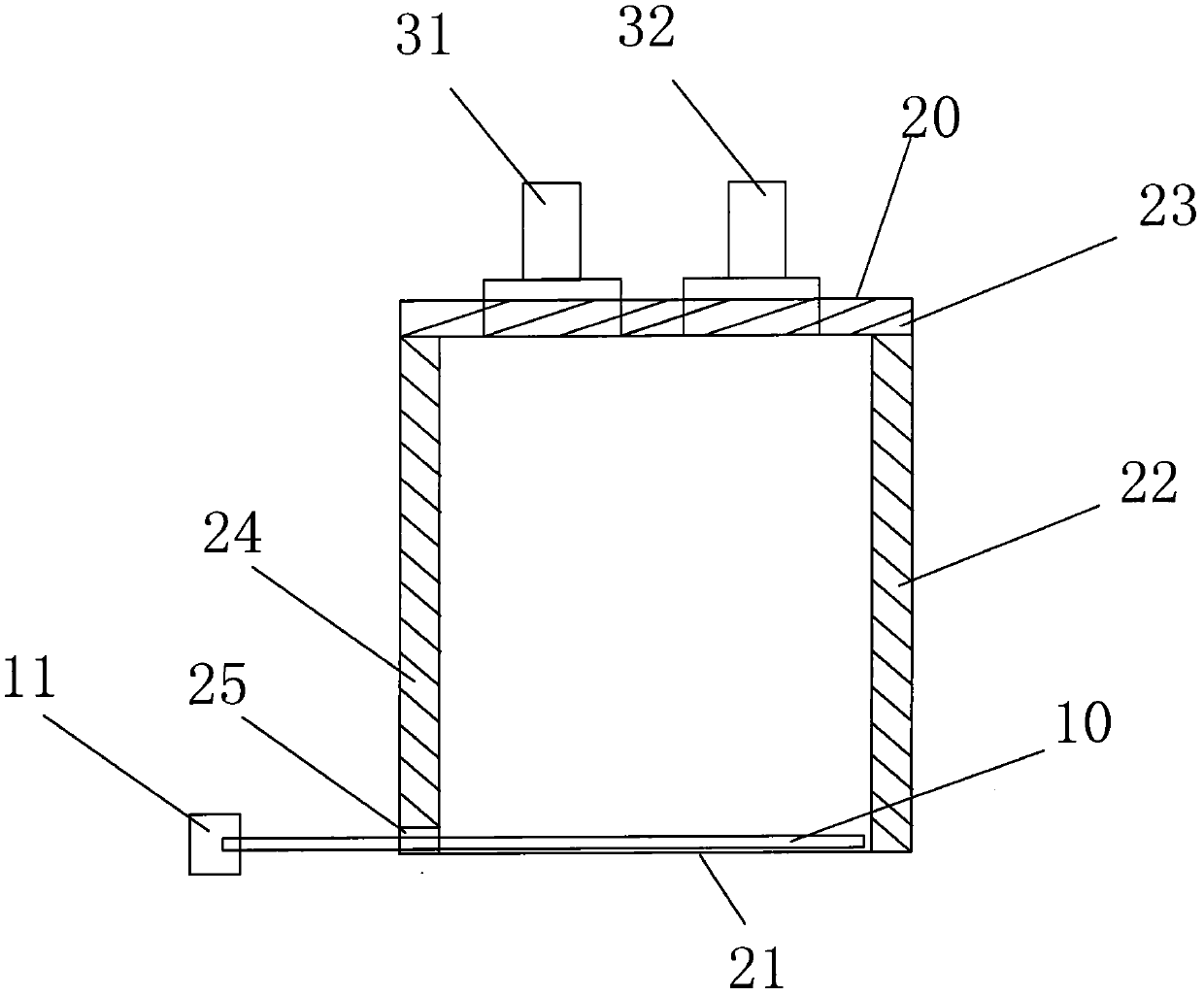

[0035] The lithium-ion battery structure of the preferred embodiment of the present invention is as figure 1 shown, see also figure 2 , which includes a sealed casing 20, the casing 20 is provided with a cell, and the outer surface of the casing 20 is provided with a positive tab 31 and a negative tab 32 connected to the cell. An air duct 10 is also provided inside the housing 20 , and a sealed hole 25 is provided on the housing 20 . One end of the airway tube 10 is opened in the shell 20, and the other end of the airway tube 10 is open to the hole 25 on the shell 20. The diameter of the hole 25 is suitable for the diameter of the airway tube 10, and the pressure of the sealing part of the hole 25 is lower than that of the shell. 20 other sealing parts. In this way, when the gas inside the battery casing 20 generates a relatively high pressure, the sealing part of the opening of the air duct 10 can be opened earlier than other parts on the casing 20, so that the gas is disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com