Hand pump for pumping fluids, and filter system for fluids, comprising a hand pump

A filter system, manual pump technology, applied to parts of pumping devices for elastic fluids, liquid fuel engines, pumps with flexible working elements, etc., can solve the problems of limited displacement height, unused, etc., to achieve simple Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

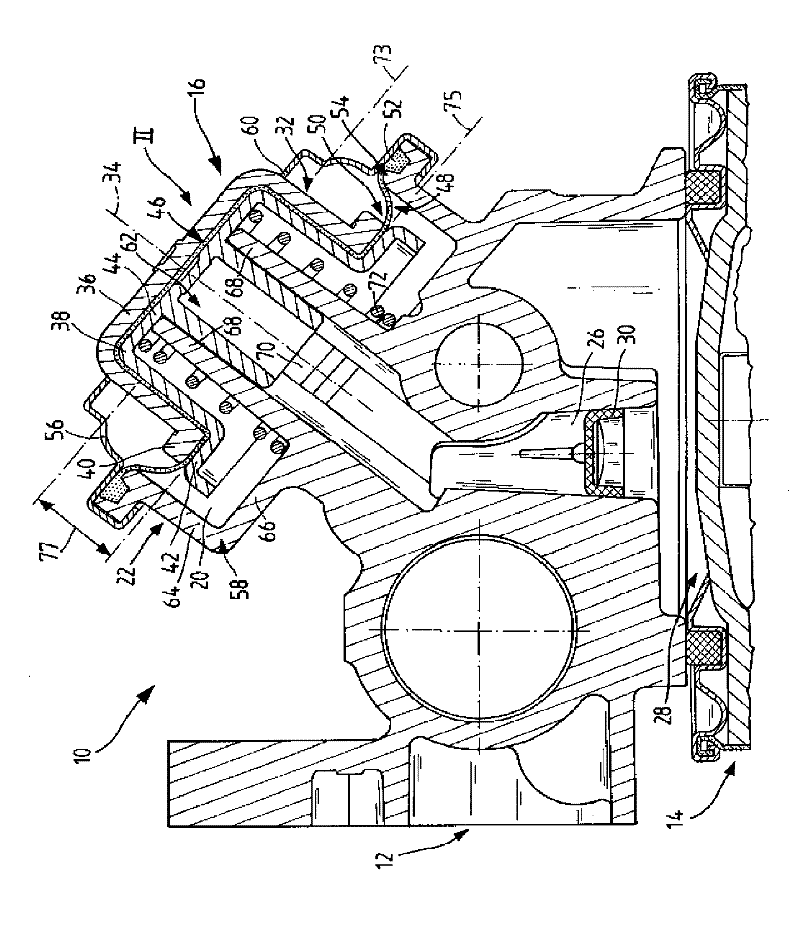

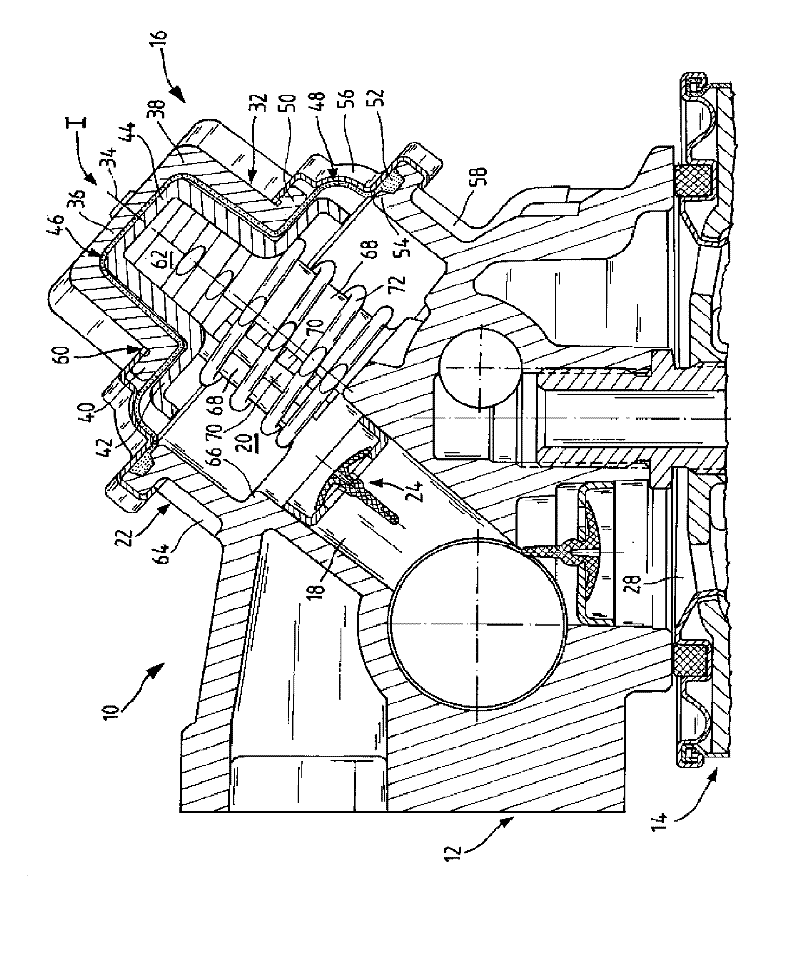

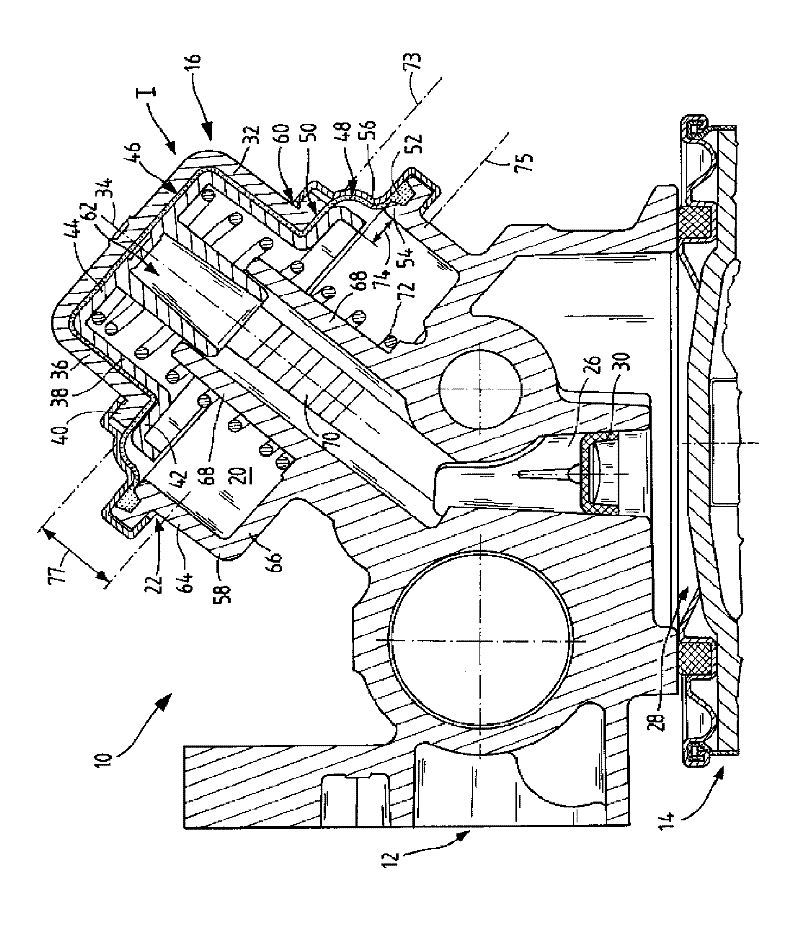

[0021] exist figure 1 A detail of a fuel filter system 10 for a motor vehicle internal combustion engine is shown in . The fuel filter system 10 comprises a filter head 12 on which a replacement filter 14 which is not of interest here is mounted.

[0022] A manual pump 16 is integrated in the filter head 12 . The hand pump 16 is used to manually draw fuel from the fuel tank, for example after replacing the replaceable filter 14 or before restarting the internal combustion engine when the fuel tank is emptied.

[0023] A suction line 18 of a hand pump 16 is arranged inside the filter head 12 . exist image 3 The suction pipe 18 is seen in the sectional view of . The suction line 18 is connected to a fuel supply line (not shown in the drawing) from the fuel tank and opens into a pump chamber 20 of a pump housing 22 of the hand pump 16 . An inlet non-return valve 24 is arranged in the intake line 18 , which opens to draw fuel into the pump chamber 20 .

[0024] exist figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com