Optical pickup device, optical disk device, and method of producing same

An optical pickup device, optical disc device technology, applied in the manufacture of optical heads, recording/reproducing by optical methods, optical recording heads, etc., to achieve the effect of preventing electrostatic damage and removing short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0032] First Embodiment: Structure of Optical Pickup Device

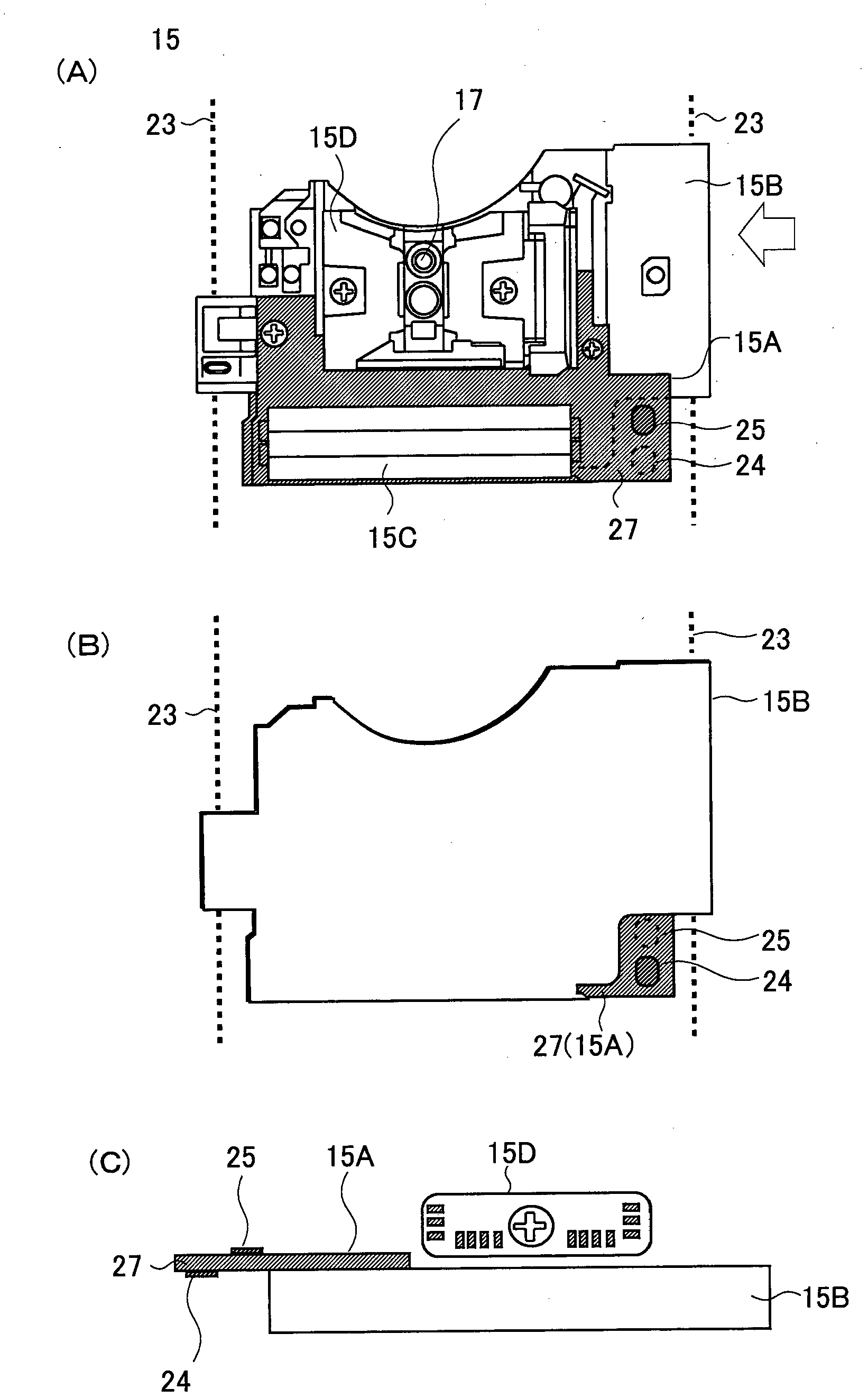

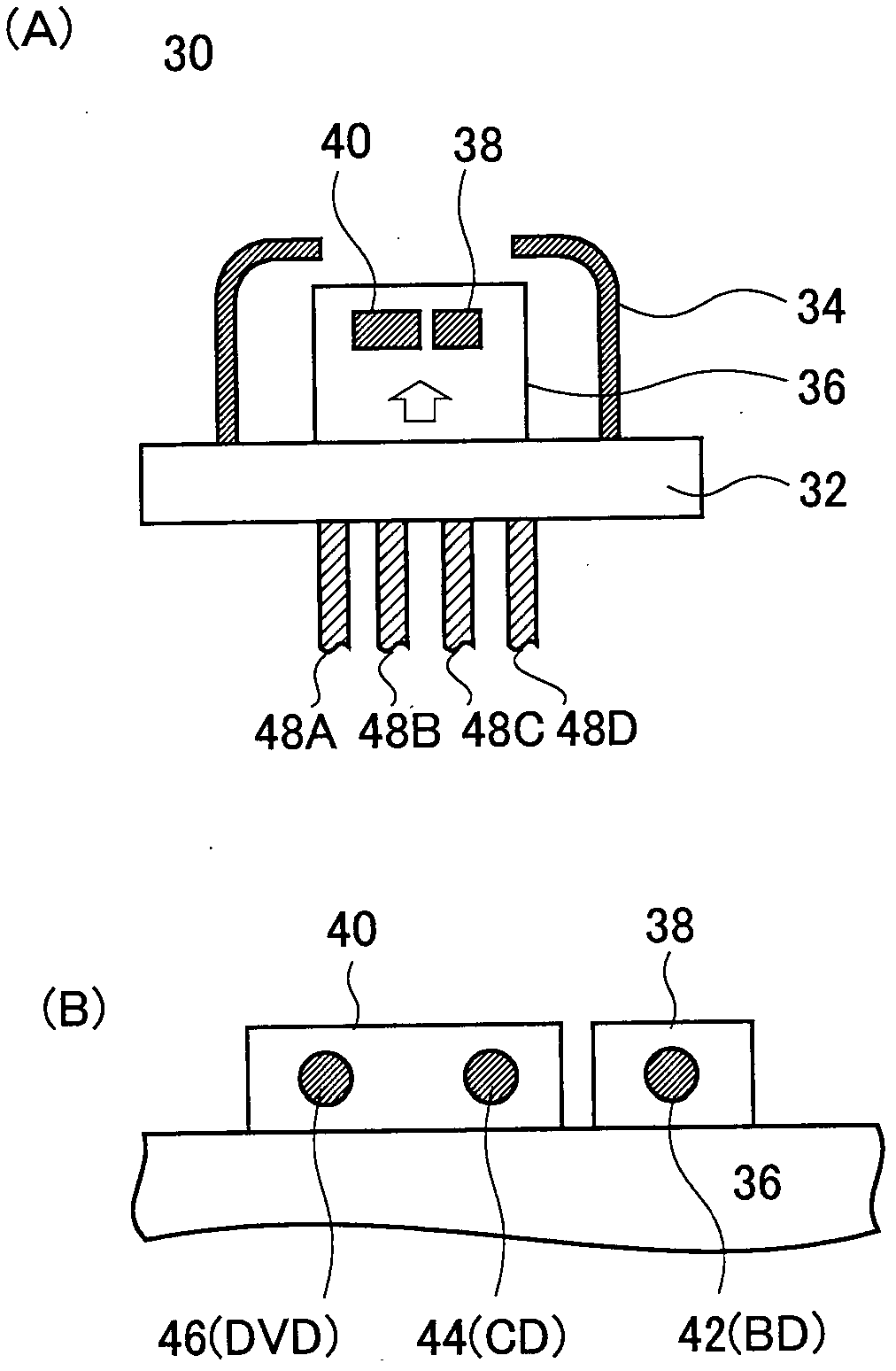

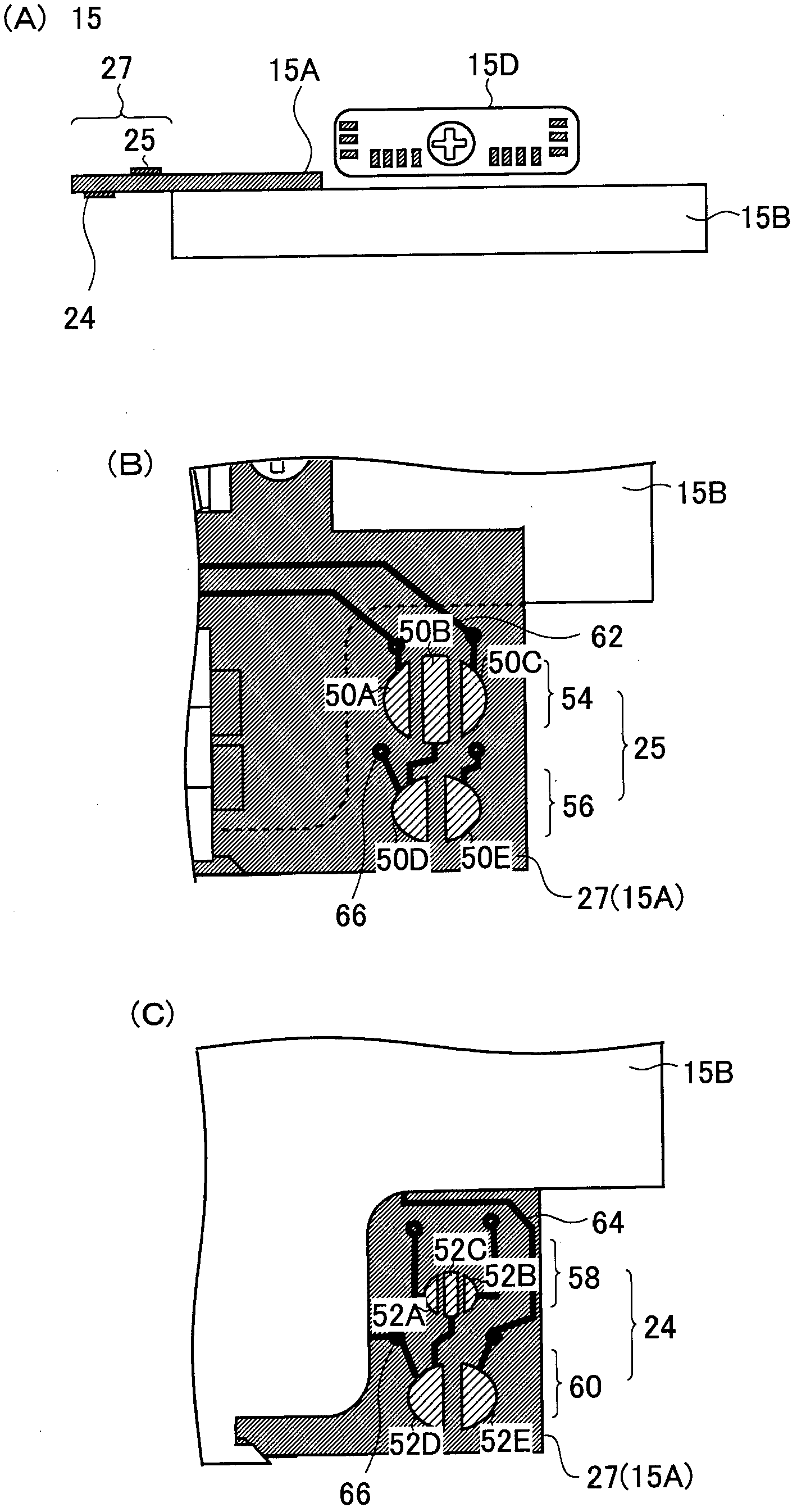

[0033] refer to Figure 1 ~ Figure 4 , to describe the structure of the optical pickup device of the present technical solution. figure 1 is a diagram showing an optical pickup device 15, figure 2is a diagram showing a laser device built in an optical pickup device, image 3 and Figure 4 It is a figure which shows the short-circuit part which is the gist of this invention.

[0034] First, refer to figure 1 The optical pickup device 15 will be described. figure 1 (A) is a top view of the optical pickup device 15 viewed from above, figure 1 (B) is a perspective view viewed from above, figure 1 (C) is from the side ( figure 1 A view of the optical pickup device observed in the direction indicated by the arrow in (A). In addition, in figure 1 Among the components of (A), the front side is referred to as the front side and the back side is referred to as the back side with respect to the sheet.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com