Cutting blade

A technology of cutting blades and blades, applied in cutting tools, cutting equipment, gardening, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

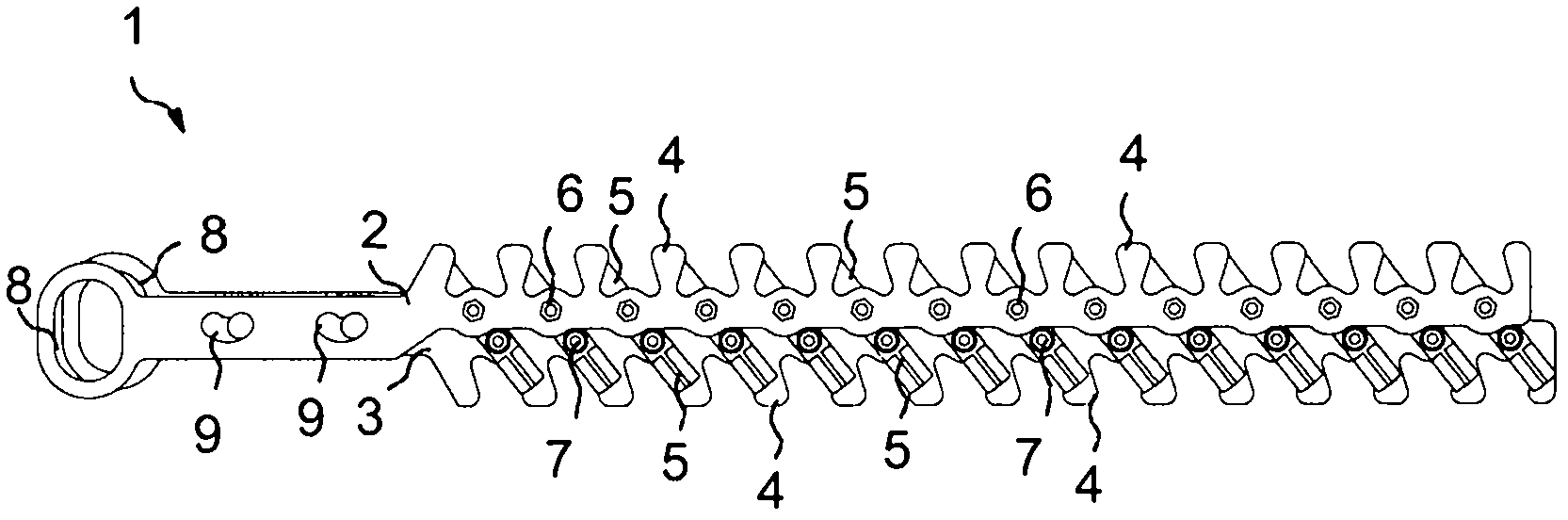

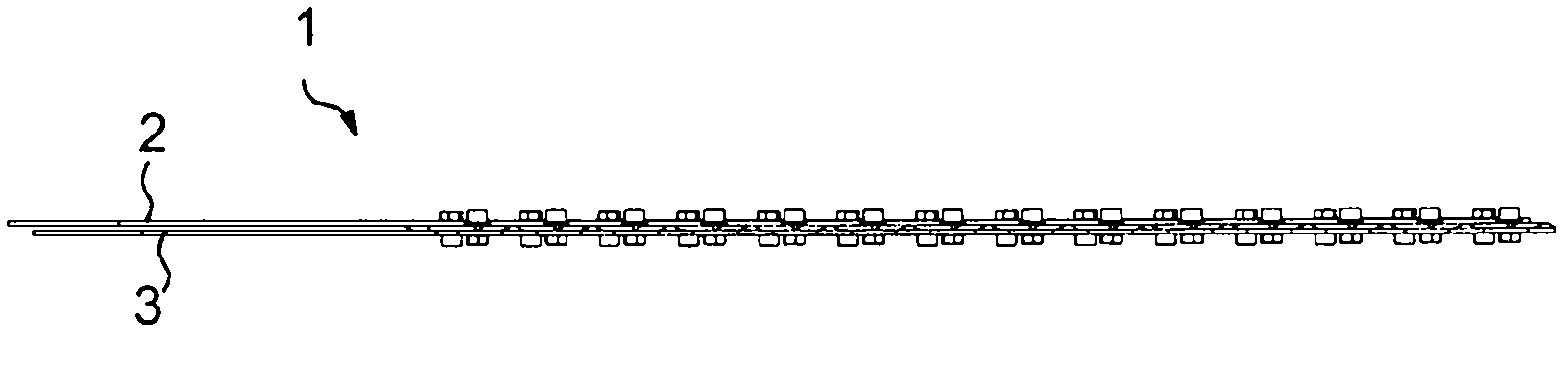

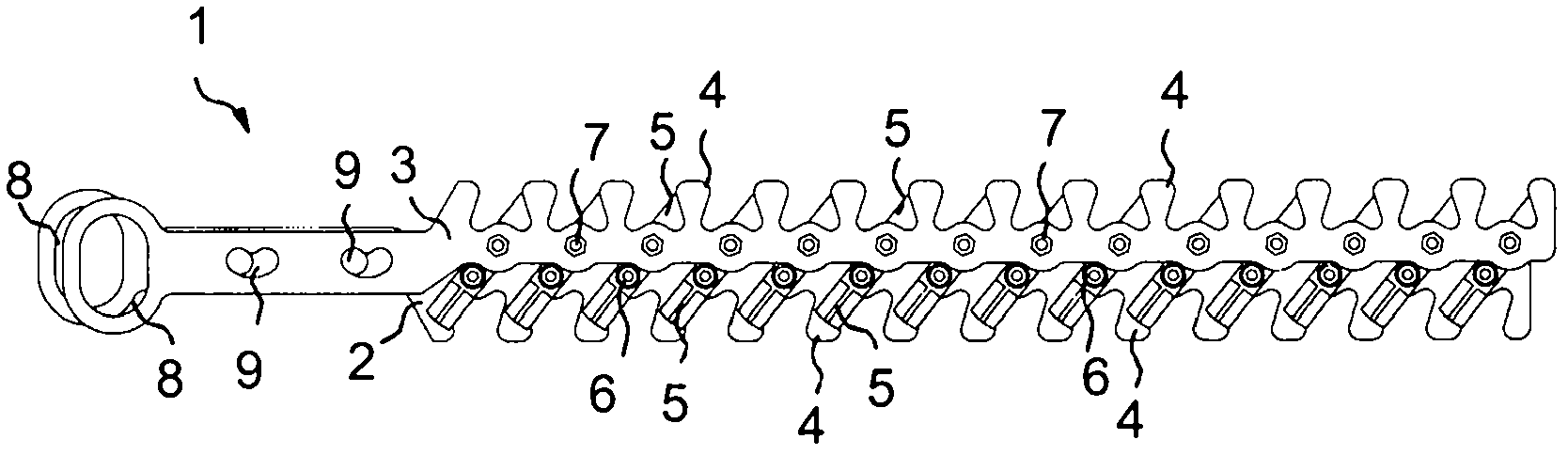

[0018] Figures 1 to 5 A first embodiment of a cutting insert 1 is illustrated. The cutting insert 1 comprises a first elongated frame part 2 and a second elongated frame part 3 . These frame sections may be made of suitable durable material such as steel. As is evident from the figures, the first frame part 2 and the second frame part 3 are arranged substantially parallel to each other.

[0019] There are projections 4 protruding from the first frame part 2 and the second frame part 3 in the transverse direction. These protrusions 4 cooperate with the blades 5 attached to the first and second frame parts 2 and 3 when the cutting blade 1 is in use, for example when cutting bushes.

[0020] The cutting insert 1 comprises a plurality of inserts 5 which, in the embodiment of the figures, are formed from generally rectangular pieces of a suitable material such as steel. Each blade 5 may be formed from a single piece whereby its upper end (as sharpened as possible) cooperates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com